What is Cow Dung Organic Fertilizer?

Definition and Composition

Cow dung organic fertilizer is a high-quality fertilizer made from cow dung as the main raw material. As a herbivorous animal, cows have feces rich in organic matter, minerals and microorganisms. When making it, fresh cow dung is first collected and then fermented under controlled temperature, humidity and ventilation conditions to kill harmful substances such as pathogens and parasite eggs, promote the decomposition and transformation of organic matter, and then crushed, screened, granulated and processed according to demand.

Historical Use in Agriculture

Cow dung organic fertilizer is rich in nutrients, with an organic matter content of 20%-30%, nitrogen, phosphorus and potassium contents of approximately 0.3%-0.45%, 0.15%-0.25%, 0.1%-0.15% respectively, and also contains a variety of trace elements. It has many advantages, can improve soil structure, enhance ventilation and water retention capacity, provide comprehensive and balanced nutrients for plants, promote growth, improve yield quality, and enhance soil microbial activity. It is environmentally friendly and pollution-free and can reduce costs. It is widely used in various crops in agricultural planting, such as vegetables and fruits, and can be used as base fertilizer and topdressing. It is also used in horticultural landscape and forestry production. However, you must use it in moderation. It can be combined with chemical fertilizers, and the appropriate fertilization method should be selected according to the crops and soil conditions.

Importance of Organic Fertilizers in Sustainable Farming

Environmental Benefits

- Avoid fecal pollution: If the large amount of cow dung produced by cattle farming is not handled properly, it will cause serious pollution to the surrounding environment, such as soil pollution, blocking rivers, and emitting foul odors. Making cow dung into organic fertilizer can reduce such pollution from the source and improve the environmental sanitation of the farm and its surroundings.

- Soil ecological restoration: Long-term use of chemical fertilizers can easily lead to soil compaction and decreased fertility. Cow dung organic fertilizer is rich in organic matter and various nutrients, which can increase the organic matter content of the soil, improve the soil structure, make the soil loose and porous, improve the soil's water and fertilizer retention capacity and aeration, and is conducive to the growth and reproduction of microorganisms in the soil, promote the balance and stability of the soil ecosystem, and repair the damaged soil ecology.

- Reduce chemical pollution: Excessive use of chemical fertilizers and pesticides can cause water pollution, soil pollution, and agricultural product pollution. Cow dung organic fertilizer has comprehensive and mild nutrients, which can replace chemical fertilizers to a certain extent and reduce the amount of chemical fertilizers used, thereby reducing the risk of eutrophication of water bodies caused by fertilizer loss and chemical pollution of soil and agricultural products, and protecting the ecological environment and biodiversity.

- Promote carbon cycle: During the fermentation and use of cow dung organic fertilizer, organic matter will be decomposed and transformed, and part of the carbon will be fixed in the soil, which will help increase the carbon storage of the soil and reduce the emission of greenhouse gases such as carbon dioxide. It has a positive effect on mitigating climate change and promoting the carbon cycle and balance of the agricultural ecosystem.

Comparison with Chemical Fertilizers

Ingredients:

- Organic fertilizer: mainly derived from organic matter such as animal and plant residues, feces, and compost, with complex and diverse ingredients. Taking the common cow dung organic fertilizer as an example, in addition to containing a large amount of organic matter (usually around 20% - 30%), it also contains a large number of elements such as nitrogen (N), phosphorus (P₂O₅), and potassium (K₂O), with contents of about 0.3% - 0.45%, 0.15% - 0.25%, and 0.1% - 0.15%, respectively, as well as calcium, magnesium, sulfur, iron, zinc, manganese and other trace elements. In addition, it also contains rich microbial communities, such as bacteria, fungi, actinomycetes, etc.

- Chemical fertilizer: It is a fertilizer made by chemical synthesis or ore processing, with relatively simple ingredients and clear nutrient content. For example, the nitrogen content of urea is as high as about 46%, the nitrogen content of diammonium phosphate is about 18%, the phosphorus content is about 46%, and the potassium content of potassium sulfate is about 50% - 52%. Chemical fertilizers mainly provide macronutrients such as nitrogen, phosphorus, and potassium, and contain less or no trace elements.

Fertilizer effect:

- Organic fertilizer: The fertilizer effect is slow and lasting. The nutrients in organic fertilizers exist in an organic state and need to be decomposed and transformed by soil microorganisms before they can gradually release nutrients that can be absorbed by plants. Therefore, after organic fertilizers are applied to the soil, the fertilizer effect is not obvious in the short term, but they can provide nutrients to plants for a long time to meet the needs of the entire growth cycle of plants.

- Chemical fertilizers: The fertilizer effect is fast. Most of the nutrients in chemical fertilizers are fast-acting and can be directly absorbed and utilized by plants. After being applied to the soil, they can provide plants with a large amount of nutrients in a short period of time, allowing plants to grow and develop rapidly. For example, during the vigorous growth period of plants, topdressing with nitrogen fertilizers such as urea can make plant leaves turn green quickly and grow faster.

Environmental impact:

- Organic fertilizer: Environmentally friendly. During the production and use of organic fertilizer, it can reduce greenhouse gas emissions and contribute to carbon emission reduction. Moreover, the organic matter in organic fertilizer can be decomposed and utilized by soil microorganisms, and no harmful substances will remain in the soil, which will not pollute the soil ecological environment and water environment.

- Fertilizer: May cause environmental pollution. Fertilizers consume a lot of energy and resources during production and emit certain greenhouse gases. During use, if excessive or unreasonable application is used, the nutrients in the fertilizer are easily lost to the water body, resulting in eutrophication of the water body, causing algae to multiply in large numbers, and destroying the aquatic ecological balance. In addition, some components in fertilizers may accumulate in the soil, causing potential harm to the soil ecological environment.

Impact on soil:

- Organic fertilizer: It can improve soil structure. The organic matter in organic fertilizers can increase the aggregation of soil, form a good aggregate structure in the soil, and improve the air permeability, water permeability and water retention of the soil. Long-term application of organic fertilizer can also improve the buffering capacity of the soil, regulate the soil pH, and make the soil more suitable for plant growth.

- Fertilizer: Long-term and large-scale application of fertilizer may cause soil compaction. Due to the high nutrient content and large application amount of fertilizer, it is easy to accumulate salt in the soil, destroy the soil aggregate structure, make the soil compact, and deteriorate the air permeability and water permeability. At the same time, long-term partial application of a certain fertilizer may also cause an imbalance in soil pH.

Nutritional Profile and Benefits of Cow Dung Fertilizer

Essential Nutrients in Cow Manure

There are many benefits of using cow dung as fertilizer. It is rich in nutrients such as nitrogen, phosphorus, potassium and organic matter. It can fertilize the soil, improve soil structure, increase water and fertilizer retention capacity, promote plant growth, and is green and environmentally friendly. It can reduce the use of chemical fertilizers, reduce environmental pollution, and increase soil microbial activity and improve soil fertility.

Nitrogen, Phosphorus, and Potassium Content

- Cow dung: Fresh cow dung usually contains about 14.5% organic matter, nitrogen content between 0.30% - 0.45%, phosphorus content between 0.15% - 0.25%, and potassium content between 0.10% - 0.15%.

- Cow dung organic fertilizer: There is little specific data on the nitrogen, phosphorus and potassium content of cow dung organic fertilizer, but generally speaking, its nutrient content will change after fermentation and other treatments. According to some data, the nitrogen content of cow dung organic fertilizer is about 0.32%, the phosphorus content is 0.25%, and the potassium content is 0.16%.

Presence of Micronutrients

There are many trace nutrients in cow dung. Here are some of the main trace nutrients and their roles in cow dung:

Iron (Fe):

Iron is an element necessary for the synthesis of chlorophyll in plants and participates in photosynthesis and respiration of plants. Although the iron content in cow dung is not high, it can provide plants with a certain amount of iron, which helps plant leaves remain green and promotes normal growth and development of plants.

Zinc (Zn):

Zinc plays an important role in the synthesis of plant growth hormones and the regulation of enzyme activity. It can promote plant growth and development, enhance plant stress resistance, and improve plant resistance to diseases and pests. The zinc element in cow dung can meet part of the plant's demand for zinc and help plants thrive.

Manganese (Mn):

Manganese is involved in plant photosynthesis, nitrogen metabolism, and redox processes. It has an important impact on plant growth, pollen germination, and seed formation. An appropriate amount of manganese can improve the photosynthesis efficiency of plants and promote plant growth and reproduction. Cow dung contains a certain amount of manganese, which can provide plants with this important trace nutrient.

Copper (Cu):

Copper is a component of many oxidases in plants and participates in plant respiration and photosynthesis. It has an impact on plant growth, reproduction and stress resistance. The copper element in cow dung can help plants maintain normal physiological functions and improve their stress resistance.

Boron (B):

Boron plays an important role in the synthesis and stabilization of pectin substances in plant cell walls, and helps plant cells to elongate and divide. It also participates in the reproductive process of plants and has an important impact on the growth and fertilization of pollen tubes. The boron element in cow dung helps promote the flowering and fruiting of plants and improve the yield and quality of crops.

Molybdenum (Mo):

Molybdenum is a component of plant nitrate reductase and nitrogenase, and is essential for plant nitrogen metabolism and nitrogen fixation. It can help plants convert nitrates into ammonia and promote the absorption and utilization of nitrogen by plants. For some leguminous plants, molybdenum can also promote the nitrogen fixation of rhizobia and improve soil fertility. The molybdenum element in cow dung can provide plants with this key nutrient element and promote plant nitrogen nutrition.

Advantages of Using Cow Dung as Fertilizer

Soil Health Improvement

Improve soil physical properties

- Increase soil porosity: After the organic matter in cow dung organic fertilizer decomposes in the soil, it can form humus, which can promote the formation of soil particles into aggregates and increase soil porosity. Studies have shown that long-term application of cow dung organic fertilizer can increase the total porosity of the soil by 10% - 20%, and the ventilation porosity by 5% - 10%, making the soil more loose and breathable, which is conducive to the growth and breathing of plant roots.

- Improve soil water retention: The formation of aggregate structure enhances the water holding capacity of the soil. Cow dung organic fertilizer can increase the field water holding capacity of the soil by 20% - 30%, which means that the soil can store more water, reduce water evaporation and loss, and provide more sufficient water supply for plant growth, especially in arid areas or dry seasons. This effect is more obvious.

Improve soil chemical properties

- Increase soil nutrient content: Cow dung organic fertilizer is rich in nitrogen, phosphorus, potassium and other macroelements as well as a variety of trace elements. Generally speaking, every 1,000 kg of cow dung organic fertilizer contains 3-5 kg of nitrogen (N), 2-3 kg of phosphorus (P₂O₅), 1-2 kg of potassium (K₂O), and trace elements such as iron, zinc, manganese, and boron. These nutrients are gradually released in the soil, providing continuous nutritional support for plant growth and increasing soil fertility.

- Regulating soil pH: Cow dung organic fertilizer is weakly alkaline and has a certain improvement effect on acidic soil. Long-term application of cow dung organic fertilizer can increase the pH value of acidic soil by 0.5-1.0 units, making it closer to the pH range suitable for plant growth, thereby improving the effectiveness of nutrients in the soil and promoting plant absorption of nutrients.

- Enhance soil fertility retention: The organic colloids and humus in organic fertilizers carry a large amount of negative charge, which can absorb cations in the soil, such as ammonium ions and potassium ions, and reduce the loss of these nutrients. Studies have found that after applying cow dung organic fertilizer, the cation exchange capacity of the soil can be increased by 20% - 30%, which greatly enhances the soil's fertilizer retention capacity and enables the soil to better preserve and supply nutrients.

Enhancement of Soil Structure and Aeration

- Increase aggregate stability: Soil aggregates are the basic units of soil structure, and their stability affects the physical, chemical and biological properties of the soil. Studies have shown that long-term application of cow dung organic fertilizer can significantly improve the stability of soil aggregates. For example, a study found that after 10 years of continuous application of cow dung organic fertilizer, the content of water-stable aggregates larger than 0.25 mm in the soil increased by 20% - 30% compared with the control soil without organic fertilizer. This is because the organic matter in cow dung organic fertilizer decomposes into humus under the action of soil microorganisms, and humus can bind soil particles together through cementation to form stable aggregates.

- Enhance soil aeration: Promote root growth: Good soil aeration is essential for the growth and development of plant roots. Cow dung organic fertilizer improves soil structure, increases soil porosity, and provides more oxygen for plant roots, thereby promoting root growth and development. Studies have found that in soils where cow dung organic fertilizer is applied, the volume and weight of plant roots can increase by 20% - 30% compared with control soils. The growth of the root system further improves the soil structure and increases the aeration of the soil, forming a virtuous cycle.

- Favorable to microbial activity: Improved soil aeration is conducive to the activity of aerobic microorganisms in the soil. These microorganisms play an important role in decomposing organic matter and converting nutrients. For example, in well-aerated soil, the number of aerobic bacteria can increase by 30% - 50% compared to poorly aerated soil. The activity of microorganisms can not only promote the release of nutrients in cow dung organic fertilizer and improve soil fertility, but also produce some organic matter, further improve soil structure and enhance soil aeration.

Promotion of Beneficial Microbial Activity

- Increase the number and activity of soil microorganisms: Cow dung organic fertilizer provides a rich food source and a good living environment for soil microorganisms, and can significantly increase the number of microorganisms such as bacteria, fungi, and actinomycetes in the soil. For example, after applying cow dung organic fertilizer, the number of bacteria in the soil can increase by 1-2 orders of magnitude, and the number of fungi can increase by 50%-100%. These microorganisms carry out various biochemical processes in the soil, such as decomposing organic matter, converting nutrients, and synthesizing humus, thereby improving the fertility and activity of the soil.

- Promote the growth of beneficial microorganisms in the soil: Beneficial microorganisms in cow dung organic fertilizer, such as rhizobia, phosphate-solubilizing bacteria, potassium-solubilizing bacteria, etc., can form a symbiotic relationship with plant roots and help plants absorb nutrients. For example, rhizobia can fix nitrogen in the air and provide nitrogen sources for plants; phosphate-solubilizing bacteria and potassium-solubilizing bacteria can convert insoluble phosphorus and potassium in the soil into forms that can be absorbed by plants. Studies have shown that after applying cow dung organic fertilizer, the relative abundance of beneficial microorganisms in the soil can increase by 10% - 20%, which helps improve the nutritional status of plants and enhance their ability to resist diseases and pests.

Reduction in Soil Erosion

- Cow dung organic fertilizer provides rich nutrients for plants and is conducive to the growth and development of vegetation. The increase in vegetation coverage can effectively block the direct impact of rainwater on the soil, slow down the runoff speed, and reduce the possibility of soil erosion.

- Related studies have shown that on land where cow dung organic fertilizer is applied, vegetation coverage can be increased by 20% - 30%, and soil erosion can be reduced by 40% - 50% accordingly. For example, in the restoration of some degraded grasslands, after the application of cow dung organic fertilizer, the height, density and biomass of grassland vegetation have increased significantly, the surface has been effectively covered, and soil erosion has been effectively controlled.

Methods of Processing Cow Dung into Organic Fertilizer

1. Traditional Processing Methods

Aerobic Composting

- Composting operation process: first collect cow dung and try to reduce its moisture content. Spread the cow dung evenly on the ground with a thickness of about 15-20 cm. Loose materials such as straw and rice straw can be added appropriately to improve air permeability. Then cover it with a layer of soil about 10 cm thick to maintain temperature and humidity.

- Fermentation process: Aerobic fermentation is divided into three stages: heating, high temperature continuation and decomposition. In the initial stage, the heating stage is medium temperature, mesophilic microorganisms use organic matter to reproduce in large quantities, and the temperature continues to rise. When the temperature rises to above 45℃ and enters the high temperature maintenance stage, the activity of thermophilic microorganisms is enhanced, soluble organic matter is continuously decomposed, and complex organic matter such as hemicellulose, cellulose and protein are rapidly decomposed. When the compost enters the decomposition stage, the activity of microorganisms decreases, the heat generated decreases, and the temperature of the pile decreases. At this time, only natural ventilation is required.

- Time and effect: Under normal circumstances, cow dung composting needs to be fermented for about 3 months to achieve good results. After composting, the organic matter in cow dung is decomposed and converted into stable humus, becoming high-quality organic fertilizer that can effectively improve soil structure and increase soil fertility.

Anaerobic Composting

- Anaerobic digestion process: First, use a solid-liquid separator to separate the collected cow dung to obtain cow dung cakes with low moisture content. Then put the cow dung cakes into an anaerobic digester, add an appropriate amount of water and microbial preparations, and make the cow dung cakes fully contact with microorganisms. Then, by adjusting the temperature, humidity, oxygen concentration and other conditions in the digester, the organic matter in the cow dung cakes is decomposed into biogas and liquid fertilizer.

- Product utilization: The generated biogas is a clean energy that can be used for power generation, heating or cooking. Liquid fertilizer is rich in nutrients and can be used to irrigate plants or make organic fertilizer to achieve effective utilization of resources.

- Note: Anaerobic digestion requires special equipment and technology, and has high requirements for site conditions and operation management. However, this method can efficiently treat cow dung, reduce environmental pollution, and achieve dual output of energy and fertilizer.

2. Modern Processing Methods

1. Vermicomposting

- Principle: Earthworms move in cow dung, decomposing and transforming organic matter in cow dung through processes such as ingestion, digestion and excretion. The intestines of earthworms contain rich microbial communities, which work synergistically with earthworms to accelerate the decomposition of complex organic matter in cow dung and transform it into nutrients that are more easily absorbed by plants.

- Processing process: First, a suitable site needs to be prepared, which can be an indoor container such as a plastic box, a wooden box, etc., or a special outdoor composting site. Then, the collected cow dung is preliminarily treated to adjust its humidity and air permeability. Generally, the humidity is kept at around 60% - 70%. Next, earthworms are introduced into the cow dung. The number of earthworms is determined according to the amount of cow dung and the treatment target. Usually, 1000 - 2000 earthworms can be placed in each square meter of compost. During the composting process, the cow dung should be turned regularly to ensure oxygen supply, and the temperature should be controlled at around 20 - 25℃, which is the suitable temperature range for earthworm growth and activity. After a period of time (usually 2-3 months), the earthworms will transform the cow dung into black, soft, earthy-scented vermicompost.

- Advantages: Compared with the traditional cow dung composting method, vermicomposting has many advantages. It can more effectively decompose the organic matter in cow dung and increase the nutrient content of fertilizer. Vermicompost is rich in nitrogen, phosphorus, potassium and various trace elements, and these nutrients exist in a form that is easily absorbed by plants. At the same time, the odor produced during vermicomposting is small and the pollution to the environment is small. In addition, vermicomposting can improve soil structure, increase soil aeration, water retention and fertilizer retention, and is conducive to the growth and development of plant roots.

- Application: The vermicompost obtained from vermicomposting is a high-quality organic fertilizer that can be widely used in agricultural production, horticultural planting and other fields. It can be directly applied to the soil to provide comprehensive nutrition for plants, promote plant growth, and increase the yield and quality of crops. In flower planting, vermicompost is also an ideal cultivation substrate that can make flowers grow strong and bright.

2. Use of Advanced fermentation process

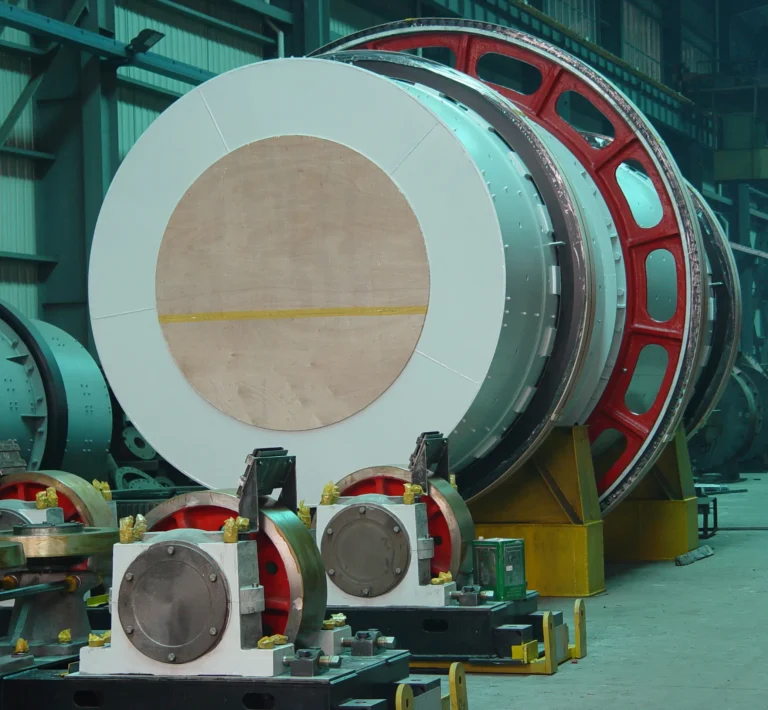

Cow dung organic fertilizer fermentation and granulation process

- Cow dung collection:

Fresh cow dung is collected from the cattle farm through dung scrapers, conveyor belts and other equipment. The water content of cow dung is required to be 70%-80%. Too high water content will affect subsequent fermentation. It can be stored in a dung storage tank for a short time to drain water.

- Addition of auxiliary materials:

In order to adjust the carbon-nitrogen ratio and improve the material structure, add straw powder, sawdust and other auxiliary materials. Generally, cow dung: auxiliary materials = 3:1 - 5:1 (volume ratio) is mixed to make the carbon-nitrogen ratio of the mixed material reach 25-30:1, which is conducive to microbial fermentation. For example, when processing 10 cubic meters of cow dung, 2-3.3 cubic meters of straw powder are added.

- Crushing:

The mixed material is crushed with a hammer mill to make the material particle size ≤5mm, increase the specific surface area of the material, and accelerate the fermentation process.

- Pile building:

The crushed material is piled into a strip pile with a height of 1.2-1.5 meters, a bottom width of 2-3 meters, and a length determined by the site. Leave a 1-1.5 meter passage between the windrows to facilitate the turning operation.

- Inoculation of microbial agents:

Adding high-efficiency composite microbial agents, such as agents containing Bacillus, actinomycetes, etc., at a weight of 0.1%-0.2% of the material can speed up the fermentation and improve the fermentation effect.

- Turning the pile:

In the early stage of fermentation, the pile is turned once every 2-3 days with a compost turner to ensure oxygen supply and even fermentation of the material. In the middle stage of fermentation (temperature reaches above 50°C), the pile is turned once every 3-5 days. The entire fermentation cycle is about 10-15 days. When the pile temperature begins to drop, the color of the material becomes darker and there is no obvious odor, indicating that the fermentation is completed. The compost turner here is Compost Turners, and common ones are crawler compost turners and wheel compost turners. The crawler compost turner has a large ground contact area and is suitable for relatively soft and humid composting sites. Its turning depth can reach 0.8-1.2 meters, and its working efficiency is to process 100-300 cubic meters of material per hour. Wheeled compost turners are highly maneuverable and easy to transfer. The compost turning width is generally 2-4 meters, and 80-200 cubic meters of materials can be processed per hour. Through compost turning, the materials are fully exposed to the air, which promotes the reproduction of aerobic microorganisms and accelerates the fermentation process.

- Secondary fermentation (aging):

The materials after primary fermentation are moved to a cool and ventilated place, piled 0.8-1 meters high, and secondary fermentation is carried out for a period of 15-20 days. This stage allows the materials to further mature and stabilize, reduce harmful microorganisms and volatile substances, and improve the quality of fertilizers.

- Fine crushing and screening:

Although the materials after secondary fermentation have been initially decomposed, there are still large differences in particle size, which requires further crushing. Choosing a claw crusher or a double-roll crusher can achieve more refined crushing. The claw crusher has high crushing efficiency and can further refine the material to a particle size range of 1-3mm; the double-roll crusher can produce more uniform and more precise particles, so that the final material particle size is mostly concentrated around 2mm. After the material is crushed, it enters the vibrating screen, and the mesh size is usually 10-12. The vibrating screen here is the Screening Machines. After screening, the screened material (particle size > 2mm) is automatically returned to the crusher through the screw conveyor for re-crushing, ensuring that all materials meet the requirements of subsequent processing and the uniformity of product particle size, laying the foundation for the accuracy of subsequent batching and mixing. The common vibrating screen has a processing capacity of 5-20 tons per hour, and the screening efficiency is 85%-95%.

Accurate batching and mixing: According to the nutrient content standard of the target fertilizer, nitrogen, phosphorus, potassium and other fertilizers and trace element additives are accurately added. Taking the production of organic fertilizer with a total nitrogen, phosphorus and potassium nutrient content of ≥40% as an example, assuming that the ratio of nitrogen (N), phosphorus (P₂O₅), and potassium (K₂O) is 15:15:10, it is calculated that about 260kg urea (nitrogen 46%), 326kg diammonium phosphate (nitrogen 18%, phosphorus 46%), and 172kg potassium sulfate (potassium 50%) need to be added to each ton of finished organic fertilizer. In addition, in order to meet the needs of different soils and crops for trace elements, appropriate amounts of additives such as borax and zinc sulfate need to be added. A high-precision electronic scale is used in the batching process to ensure that the error of the addition amount of each raw material is controlled within ±0.1%. All raw materials are put into a double-shaft paddle mixer, which has high mixing efficiency and good mixing uniformity. The mixing time is set to 15-20 minutes. Through regular sampling and testing, the coefficient of variation of material uniformity is guaranteed to be ≤5%, ensuring that the nutrient content of each part of the fertilizer is consistent. - Efficient granulation:

The granulation process can be done with a disc granulator or an extrusion granulator, both of which belong to Granulators. The disc granulator uses a rotating disc to gradually aggregate the material into balls under the action of centrifugal force, friction and gravity. Its ball formation rate is ≥85%, and the particle size of the produced particles is between 2-4mm, which is relatively round. During operation, the disc speed is generally controlled at 25-35r/min, and the material stays in the disc for about 3-5 minutes. In order to improve the granulation effect, a proper amount of water can be sprayed on the material through a nozzle or low-pressure steam can be introduced to keep the material humidity at 12%-15% to improve the particle forming effect. The extrusion granulator uses mechanical pressure to squeeze the material through a die to form columnar particles, which are then cut to obtain fertilizer particles of the required length. The particles produced by this method have higher strength and can better meet the requirements of transportation and storage, especially for products sold over long distances. The pressure parameters of the extrusion granulator are adjusted according to the material characteristics and particle requirements, generally controlled at 5-10MPa, and the particle cutting length can be accurately set to ensure that the product particle size is consistent. The disc granulator has an hourly output of 1-5 tons, and the extrusion granulator has an hourly output of 0.5-3 tons.

- Deep drying:

The fertilizer after granulation contains a certain amount of moisture and needs to be dried. A rotary dryer is used to achieve heat transfer by countercurrent contact between hot air and materials. This rotary dryer is called Dryers. The temperature in the dryer is controlled at 80-120℃. The temperature in the front section is higher to accelerate the evaporation of water, and the temperature in the back section is slightly lower to avoid excessive drying of the material or nutrient loss. The residence time of the material in the dryer is controlled by adjusting the feed speed and the drum speed, generally 15-30 minutes. The dryer is equipped with a hot air blower, and the hot air temperature can be adjusted according to the drying conditions of the material, and the thermal efficiency can reach 60%-70%. The moisture content of the fertilizer at the outlet is monitored in real time through an online moisture detector to ensure that the final moisture content drops below 10%, which meets the requirements of national standards, ensures stable product quality, and prevents caking and deterioration during storage. The processing capacity of the rotary dryer can usually process 3-10 tons of materials per hour.

- Rapid cooling:

The temperature of the fertilizer after the dryer is high and needs to be cooled in time. The cooler adopts air cooling, using the fan to introduce cold air from the outside, and fully contact with the hot fertilizer to achieve heat exchange. This type of cooling equipment belongs to the category of Coolers. During the cooling process, the temperature of the fertilizer drops rapidly from 80-120℃ to 30-40℃. The cooling time is controlled at 8-12 minutes to avoid the fertilizer absorbing moisture in the air due to too long cooling time. Multi-layer guide plates are set in the cooler to make the fertilizer more evenly distributed during the cooling process and the cooling effect more stable. The temperature of the cooled fertilizer is suitable, which is convenient for subsequent screening, impurity removal and packaging operations, and can effectively extend the shelf life of the product. The processing capacity of the cooler matches that of the dryer, and can process 3-10 tons of materials per hour.

- Screening and impurity removal:

The cooled fertilizer is screened again by a vibrating screen, and the mesh size is generally 8-10 meshes, mainly to remove a small amount of large particles or mixed impurities that may be produced during the production process, such as incompletely crushed straw segments, metal debris caused by equipment wear, etc. Screening Machines are used again here to further ensure the appearance quality of the product, improve the product grade, and make the product more in line with market sales standards.

- Measuring and packaging:

Automatic quantitative packaging scales are used for packaging, and this type of equipment is Packaging Machines. The packaging scale has high precision, and the weight error of each bag is controlled within ±0.5kg. The packaging material is a moisture-proof woven bag with good moisture-proof performance, which can effectively prevent the fertilizer from being affected by moisture during storage and transportation. The sealing process uses heat sealing or seaming to ensure that the seal is firm and does not leak. The packaged products are neatly stored in batches in a cool, dry warehouse. The warehouse floor needs to be raised by 10-20cm to prevent the products from directly contacting the ground and getting wet. The products are stored in accordance with the first-in-first-out principle for easy management and sales, waiting to be shipped out of the factory. The automatic quantitative packaging scale can pack up to 5-20 tons per hour, and different models can be selected according to the production scale.

3. Use of Advanced Machinery

Compost Turners

- Efficient turning: Tongli compost turning machine has a large turning width and depth, and can handle a large area of cow dung compost at one time. For example, its turning width can reach 3-5 meters, and its depth can reach 0.8-1.2 meters, which greatly improves the efficiency of compost turning, enables cow dung compost to fully contact the air, and accelerates the aerobic fermentation process.

- Even mixing: The equipment uses special turning knives and stirring devices to evenly mix cow dung with added microbial agents, auxiliary materials, etc. Through precise knife design and speed control, it ensures that the compost material is evenly mixed during the turning process, which is conducive to the uniform distribution of microorganisms in the compost, promotes the consistency of fermentation, and improves the quality of compost.

- Intelligent control: Equipped with an advanced intelligent control system, it can automatically adjust the frequency and speed of turning according to the fermentation stage and process requirements of the compost. For example, in the early stage of compost fermentation, a higher turning frequency can be set, 2-3 times a day, to promote the full entry of oxygen into the compost; as the fermentation progresses, the turning frequency is gradually reduced to 2-3 times a week. This intelligent control not only improves the composting effect, but also saves labor costs.

- Environmentally friendly design: Taking environmental factors into consideration, the Tongli compost turner generates less noise and dust pollution during operation. It adopts a closed design to reduce the flying of dust, and is equipped with advanced noise reduction devices to control the equipment operating noise below 70 decibels, which meets environmental protection standards and reduces the impact on the surrounding environment.

Granulators

- Multiple granulation methods are available: Tongli granulator provides multiple granulation methods, such as disc granulation, drum granulation and extrusion granulation, etc. The appropriate granulation method can be selected according to different cow dung organic fertilizer formulas and product requirements. For example, disc granulation is suitable for producing granular fertilizers with uniform particle size and high strength. The roundness of the particles is good, which is conducive to the packaging and storage of fertilizers; extrusion granulation is suitable for producing organic fertilizer particles with high nutrient content and high density, which can meet the needs of different users for fertilizer particle characteristics.

- High-precision granulation: The equipment has high-precision granulation control technology, which can accurately control the particle size and shape of the particles. By adjusting the parameters of the granulator, such as disc speed, material addition amount, water spray flow rate, etc., various specifications of organic fertilizer particles with a particle size between 2-5 mm can be produced, and the particle size error is controlled within ±0.5 mm, ensuring the consistency and stability of the product.

- High production efficiency: Tongli granulator has a high production capacity and can meet the needs of large-scale cow dung organic fertilizer production. Taking the disc granulator as an example, its output can reach 3-5 tons per hour, and it can run continuously and stably, which greatly improves production efficiency and reduces production costs.

- Strong durability: The key components of the granulator are made of high-quality wear-resistant materials, such as the granulating disc, drum lining and extrusion die, which have high wear resistance and corrosion resistance. These components have undergone a special heat treatment process, and their hardness and toughness have been optimized. They can withstand long-term high-intensity work, reduce the frequency of equipment maintenance and replacement, and increase the service life of the equipment.

Dryers and Coolers

- Efficient drying: Tongli dryer adopts advanced heat exchange technology, which can quickly and effectively remove moisture from cow dung organic fertilizer particles. Its drying temperature can be flexibly adjusted between 50-80℃, and the appropriate drying temperature can be selected according to different material characteristics and production requirements. For example, for cow dung organic fertilizer particles with high water content, a higher temperature (70-80℃) can be used for rapid drying first, and then the temperature can be gradually reduced to 50-60℃ for low-temperature drying to ensure that the nutrients in the fertilizer are not destroyed. The dryer has a large production capacity and can process 3-8 tons of organic fertilizer particles per hour, reducing the moisture content of the material from 30%-40% to below 10%-15%, meeting the packaging and storage requirements of the product.

- Uniform drying: A reasonable material conveying system and ventilation system are designed inside the equipment to ensure that the organic fertilizer particles are heated evenly during the drying process. By adopting a multi-layer flip drying structure or a rotary drying drum, the material is constantly tumbling and moving during the drying process, avoiding local overheating or uneven drying. At the same time, the ventilation system can timely discharge the water vapor generated during the drying process, ensure the consistency of the drying effect, and improve the product quality.

- Good cooling effect: Tongli cooler uses air cooling or water cooling to quickly cool the dried organic fertilizer particles. The air-cooled cooler uses forced ventilation to make the cold air fully contact with the hot particles to achieve rapid cooling; the water-cooled cooler uses circulating water to cool the particles, which has higher cooling efficiency. The temperature of the cooled organic fertilizer particles can be reduced to below 30°C, which is convenient for subsequent packaging and storage. The cooling speed of the cooler is fast, and a large number of organic fertilizer particles can be cooled to a suitable temperature in a short time, ensuring the continuity of production.

- Energy-saving design: The design of the dryer and cooler fully considers energy-saving factors. The use of efficient heating elements and insulation materials reduces heat loss and energy consumption. At the same time, the ventilation system and water circulation system of the cooler use energy-saving motors and intelligent control systems, which automatically adjust the operating parameters according to the temperature and flow of the material, realize the rational use of energy, and reduce production costs.

Screening Machines

- Precise screening: Tongli screening machine adopts high-precision screen and advanced screening technology, which can accurately grade and screen cow dung organic fertilizer particles according to different particle sizes. The aperture specifications of the screen are complete, and the appropriate screen can be selected according to product requirements, such as 2 mm, 3 mm, 4 mm, etc. The screening machine has high screening efficiency and can accurately separate particles whose particle size does not meet the requirements, making the particle size distribution of the product more uniform, improving the quality and market competitiveness of the product.

- High processing capacity: The equipment has a large screening area and a high screening speed, which can meet the needs of large-scale production. Its screening processing capacity per hour can reach 5-10 tons, and it can operate continuously and stably, ensuring the rapid screening and grading of organic fertilizer particles on the production line. At the same time, the feed and discharge ports of the screening machine are reasonably designed, which is convenient for the transportation and collection of materials and improves production efficiency.

- Durability and reliability: The main components of the screening machine are made of high-quality wear-resistant materials, such as screens, vibration motors and frames, which have high wear resistance and corrosion resistance. The vibration motor adopts advanced technology and high-quality bearings, with stable operation, low noise and long service life. The equipment has a reasonable structural design, strong anti-seismic performance and stability, and can operate reliably for a long time in harsh production environments, reducing equipment maintenance and downtime.

- Intelligent control: Equipped with an intelligent control system, it can automatically adjust the parameters of the screening machine such as vibration frequency, amplitude and feed speed according to production needs. The screening of the material is monitored in real time through sensors. When the screening effect is found to be unsatisfactory, the system will automatically adjust the relevant parameters to ensure the stability of the screening quality. This intelligent control function not only improves the screening efficiency and quality, but also reduces the difficulty and labor intensity of manual operation.

Packaging Machines

- High-precision metering: Tongli packaging machine adopts advanced metering device, which can accurately measure and control the weight of each bag of cow dung organic fertilizer. The metering accuracy can reach within ±0.1 kg, ensuring the accuracy and consistency of product packaging weight. Whether it is a small package (such as 1 kg, 5 kg) or a large package (such as 25 kg, 50 kg), accurate metering can be achieved to meet the needs of different users.

- Multiple packaging forms: Support multiple packaging forms, such as valve bag packaging, open bag packaging and woven bag packaging. Valve bag packaging has the characteristics of good sealing and fast packaging speed, which is suitable for automated packaging production lines; open bag packaging is convenient for users to take fertilizer when using it, which is suitable for some customers who have special requirements for packaging forms; woven bag packaging has the advantages of high strength and good moisture resistance, which is suitable for long-distance transportation and storage. The packaging machine can automatically complete different forms of packaging according to the user's choice, which improves the packaging adaptability and market competitiveness of the product.

- High-speed packaging: It has a high packaging speed and can meet the packaging needs of large-scale production. Generally speaking, the packaging speed of the packaging machine can reach 200-500 bags per hour, and the specific speed depends on the packaging specifications and material characteristics. By adopting advanced automatic control systems and efficient packaging mechanisms, the rapid transportation, metering and packaging of materials are realized, which greatly improves production efficiency and reduces the labor intensity and cost of manual packaging.

- High degree of automation: Tongli packaging machine realizes fully automated operation from material transportation, metering, packaging to sealing and labeling. The equipment is equipped with advanced sensors and control systems, which can automatically detect the position and status of materials and realize a series of actions such as automatic bagging, filling and sealing. At the same time, it can also be seamlessly connected with upstream production equipment and downstream palletizing equipment to form a complete automated packaging production line, which improves the automation level and overall efficiency of production. In addition, the packaging machine also has automatic fault diagnosis and alarm functions, which is convenient for operators to find and deal with problems in time, ensuring the smooth progress of the packaging process.

Application Techniques for Cow Dung Fertilizer

1. Preparing Cow Dung for Use

Adjust humidity: Appropriate humidity is one of the key factors in cow dung fermentation. Generally speaking, the initial humidity of cow dung is around 70% - 80%, while the humidity range suitable for fermentation is 50% - 60%. Therefore, the humidity of cow dung needs to be adjusted according to the actual situation. If the humidity is too high, some dry straw, sawdust and other absorbent materials can be added to reduce the humidity; if the humidity is low, water can be sprayed appropriately. For example, for every 1000 kg of cow dung, if the humidity is higher than 60%, 100 - 200 kg of straw can be added to adjust the humidity.

Drying and Aging

- Add microbial agents: In order to speed up the fermentation of cow dung and improve the fermentation effect, some special microbial agents are usually added. These agents contain a variety of beneficial microorganisms, such as Bacillus, actinomycetes, yeast, etc., which can decompose organic matter in cow dung and convert it into nutrients that are more easily absorbed by plants. Generally, 0.5-1 kg of microbial agent is added to every cubic meter of cow dung. The agent can be thoroughly mixed with the cow dung to promote the reproduction and growth of microorganisms in the cow dung.

- Natural drying: Spread the preliminarily treated cow dung in a well-ventilated and sunny place for natural drying. The site is preferably a cement floor for easy collection and cleaning. The thickness of the cow dung is generally 20-30 cm, which is conducive to air circulation and water evaporation. In sunny weather, after 3-5 days of drying, the humidity of the cow dung can be reduced to about 30%-40%. For example, in the hot summer season, the sun is strong and the water evaporates quickly, so the drying time will be relatively short; while in winter or rainy weather, the drying time will be extended.

- Mechanical drying: For large-scale cow dung treatment, mechanical drying methods are often used, such as rotary dryers, airflow dryers, etc. These drying equipment can quickly and effectively reduce the humidity of cow dung. Taking the rotary dryer as an example, the drying temperature is generally controlled at 80-120℃, and the residence time of cow dung in the dryer is 1-2 hours. After drying, the humidity of the cow dung can be reduced to 10%-20%, which greatly improves the drying efficiency and is not affected by weather conditions.

Creating Cow Dung Cakes

- Raw material mixing: Mix the aged cow dung with an appropriate amount of binder (such as starch, bentonite, etc.) evenly. The function of the binder is to make the cow dung better shaped. Generally speaking, 5-10 kg of binder is added to every 100 kg of cow dung. At the same time, some other additives such as trace elements, water retaining agents, etc. can be added as needed to improve the quality and fertilizer efficiency of cow dung cakes. For example, adding an appropriate amount of trace elements such as boron and zinc can meet the needs of plants for these trace elements and promote the growth and development of plants.

- Molding and production: Put the mixed raw materials into the mold for pressing to make cow dung cakes. The shape and size of the mold can be designed according to actual needs. Common cow dung cakes are round, square, etc., with a diameter of 5-10 cm and a thickness of 2-3 cm. Pay attention to controlling the pressure during the pressing process so that the cow dung cake has a certain hardness and strength for easy handling and storage. Usually mechanical pressing is used, which has high production efficiency. For example, a hydraulic briquetting machine can produce 500-1000 cow dung cakes per hour.

- Drying and packaging: The finished cow dung cakes need to be dried again to remove the residual moisture and prevent mold and deterioration. Natural drying or mechanical drying can be used to reduce the humidity of the cow dung cakes to less than 10%. The dried cow dung cakes can be packaged, usually in plastic bags or woven bags. The weight of each bag depends on market demand. Common specifications include 5 kg, 10 kg, and 20 kg. The packaged cow dung cakes can be put on the market as finished organic fertilizers for soil improvement and plant fertilization in agricultural production.

2. Preparing Cow Dung for Use

Soil Incorporation

Before planting, spread the cow dung organic fertilizer evenly on the surface, and then mix it into the soil by plowing, rotary tillage, etc. The mixing depth is generally about 20-30 cm to ensure that the organic fertilizer is fully mixed with the soil. The application amount is different for different soil types and crops. For example, in sandy soil, due to its poor fertilizer and water retention capacity, the application amount can be appropriately increased, generally 3-5 tons per mu; while in clay soil, 2-3 tons per mu is sufficient. For crops with large fertilizer requirements such as vegetables, the application amount can be appropriately increased; for some crops that are resistant to barrenness, the application amount can be relatively reduced.

Top Dressing

Principle: During the growth period of plants, according to the growth stage and fertilizer requirements of crops, cow dung organic fertilizer is applied to the soil surface or around the plants to supplement the nutrients needed in the growth process of crops and meet the nutritional needs of crops in different growth periods.

- Strip application: Dig a ditch between the rows of crops, apply cow dung organic fertilizer into the ditch, and then cover with soil. The depth of the ditch is generally 10-15 cm. Water it in time after fertilization to promote the dissolution and absorption of nutrients. This method is suitable for row-sown crops such as wheat and corn.

- Hole application: Dig holes around the plants, apply organic fertilizer into the holes, and then cover with soil. The depth and diameter of the holes are generally 10-15 cm, and the amount of fertilizer per hole depends on the type of crop and its growth conditions. This method is suitable for crops with large plant spacing such as fruit trees and vegetables.

- Broadcasting: Spread the cow dung organic fertilizer evenly on the soil surface, and then combine it with tillage and watering to allow nutrients to penetrate into the soil. Broadcasting is suitable for densely planted crops or crops with shallow root distribution, but when broadcasting, care should be taken to avoid direct contact between the fertilizer and the plant to avoid burning the leaves and roots.

Liquid Fertilizer Preparation and Use

- Preparation: The collected cow dung is pre-treated to remove impurities such as stones and plastics. Then, the cow dung is mixed with water in a certain ratio, usually between 1:3 and 1:5. Then, an appropriate amount of microbial agents are added, which can accelerate the decomposition and fermentation process of the cow dung. During the fermentation process, it is necessary to stir regularly to ensure the supply of oxygen and promote the growth and metabolism of microorganisms. The fermentation time is generally 7 to 14 days, depending on the ambient temperature and the activity of the microorganisms. After the fermentation is completed, the liquid part is separated from the solid residue by filtering or centrifugation, and the resulting liquid is the cow dung liquid fertilizer.

- Use: Cow dung liquid fertilizer can be used for irrigation, foliar spraying, etc. When used for irrigation, it can be diluted and applied to the soil through drip irrigation, sprinkler irrigation and other systems. When used for foliar spraying, the liquid fertilizer needs to be further diluted, usually between 500 and 1000 times, to avoid damage to plant leaves. The spraying time is generally chosen in the morning or evening, and avoid strong sunlight to prevent the fertilizer from evaporating too quickly or burning the leaves.

Steps to Create Cow Dung Liquid Fertilizer

- Raw material collection and pretreatment: Collect fresh cow dung and try to avoid mixing too much debris. Dry the cow dung or mechanically dehydrate it to reduce its water content to about 50% - 60% for subsequent processing.

- Mixing and adding water: Mix the pretreated cow dung and water in a suitable proportion to make the water content of the mixture reach 70% - 80%. This water content range is conducive to the activity of microorganisms and the fermentation process.

- Add microbial agents: Add 0.5-1 kg of microbial agents per ton of cow dung, and evenly spread the agents on the cow dung mixture. Microbial agents contain a variety of beneficial microorganisms, such as Bacillus, lactic acid bacteria, yeast, etc., which can decompose organic matter in cow dung and produce various nutrients.

- Fermentation: Put the cow dung mixture with added agents into the fermentation tank for aerobic fermentation. During the fermentation process, the compost should be turned regularly, generally every 1-2 days, to ensure sufficient oxygen supply, promote the rapid reproduction of microorganisms and the decomposition of organic matter. The fermentation temperature will gradually increase, generally reaching 50-60℃ within 3-5 days, and maintain this temperature for a period of time to kill pathogens and parasite eggs in cow dung. The entire fermentation process lasts 7-14 days.

- Solid-liquid separation: After the fermentation is completed, solid-liquid separation is performed using filtering equipment or centrifuges. The separated solid part can be further made into solid organic fertilizer, while the liquid part is the original liquid of cow dung liquid fertilizer.

- Dilution and storage: Dilute the original liquid to a suitable concentration according to different purposes of use. If it is not used temporarily, the liquid fertilizer should be stored in a cool, ventilated place, away from direct sunlight to prevent deterioration.

Benefits of Liquid Application

- Fast nutrient absorption: The nutrients in liquid fertilizer exist in the form of ions or small molecules, which can be quickly absorbed by the plant roots and quickly meet the needs of plant growth and development. Compared with solid fertilizers, liquid fertilizers do not need to go through the dissolution and conversion process after being applied to the soil, and are directly absorbed and utilized by plants, which greatly improves the utilization efficiency of nutrients. For example, in vegetable planting, the use of cow dung liquid fertilizer for foliar spraying can make vegetable leaves greener in a short time and significantly accelerate the growth rate.

- Precision fertilization: The nutrient content and proportion of liquid fertilizers can be accurately adjusted according to the nutrient requirements of different crops and different growth stages to achieve precise fertilization. Through irrigation systems or spraying equipment, fertilizers can be accurately applied to the roots or leaf surfaces of plants, avoiding fertilizer waste and pollution to the environment. For example, at different stages of fruit tree growth, the formula of liquid fertilizers can be adjusted according to their needs for nutrients such as nitrogen, phosphorus, and potassium to provide the most suitable nutrient supply for fruit trees and improve the yield and quality of fruits.

- Improve soil structure: During irrigation, liquid fertilizer can penetrate into the soil evenly, improve the physical structure of the soil, increase the porosity and air permeability of the soil, and facilitate the growth and development of plant roots. At the same time, the organic matter and microorganisms in the liquid fertilizer can promote the reproduction of beneficial microorganisms in the soil, enhance the fertility of the soil and its ability to retain water and fertilizer. Long-term use of cow dung liquid fertilizer can make the soil more loose and fertile, and improve the sustainable utilization of the soil.

- Reduce environmental pollution: Compared with traditional solid fertilizers, the application amount of liquid fertilizer is relatively small, and it can be fully absorbed and utilized by plants, reducing the residue and loss of fertilizer in the soil, thereby reducing the risk of pollution to the water body and soil environment. In addition, during the preparation of cow dung liquid fertilizer, it is fermented to reduce the odor and harmful substances in the cow dung, making it more environmentally friendly.

- Improve crop quality: Liquid fertilizer can provide crops with a comprehensive and balanced nutrient supply, promote the growth and development of crops, and improve the resistance of crops to diseases and pests and stress. Crops fertilized with liquid fertilizers have brighter colors, better taste, and richer nutrition, and their quality has been significantly improved. For example, in strawberry cultivation, using cow dung liquid fertilizer for drip irrigation makes the strawberry fruits bigger, sweeter, and higher in vitamin C, which is deeply loved by consumers.

3. Application Rates and Timing

- Fertilizer application amount: The application amount of cow dung organic fertilizer needs to be determined according to factors such as soil fertility, crop type, and target yield. Generally speaking, for soil with medium fertility, 2000-3000 kg of cow dung organic fertilizer can be applied per mu when planting vegetables; for planting grain crops such as wheat and corn, the application amount per mu is about 1500-2000 kg. If the soil fertility is low, the application amount can be appropriately increased; if the fertility is high, the amount can be reduced. For example, when planting tomatoes in soils lacking nitrogen, phosphorus, and potassium, with a target yield of 5000 kg per mu, according to the soil nutrient test results and the nutrient requirements of tomatoes, it may be calculated that 3000 kg of cow dung organic fertilizer may be needed per mu to provide sufficient nitrogen, phosphorus, potassium and other trace elements.

- Fertilization time: Cow dung organic fertilizer is usually applied to the soil as a base fertilizer before planting. For annual crops, such as corn planted in spring, you can evenly spread cow dung organic fertilizer on the surface before ploughing in spring, and then plow it into the soil to fully mix the fertilizer with the soil, which is conducive to the crops absorbing nutrients in the fertilizer in the early growth stage. For perennial fruit trees, such as apple trees, you can dig a trench near the drip line of the crown after the fruit is harvested in autumn, apply cow dung organic fertilizer, and then cover it with soil. Fertilization in autumn is conducive to the root system of fruit trees absorbing nutrients before winter, enhancing the tree's vigor, and laying the foundation for growth and fruiting in the next year.

Recommendations for Different Crops

- Leafy vegetables: such as cabbage and spinach, mainly require nitrogen fertilizer, and also require an appropriate amount of phosphorus and potassium. Cow dung organic fertilizer is rich in nitrogen and a variety of trace elements, which is very suitable for leafy crops. Before planting leafy vegetables, the cow dung organic fertilizer is fully decomposed and evenly spread on the soil surface, and then plowed into the soil, with an application rate of about 2000-2500 kg per mu. During the growth period of leafy vegetables, topdressing can be carried out according to the growth situation. Each time, an appropriate amount of decomposed cow dung organic fertilizer liquid or biogas slurry is applied, which helps the growth of leaves and improves yield and quality.

- Fruits and vegetables: such as tomatoes and cucumbers, have a relatively balanced demand for nitrogen, phosphorus and potassium during the growth process, and also have certain requirements for trace elements such as calcium and magnesium. Before planting fruit and vegetable crops, basal fertilizer should be applied heavily, and 2500-3000 kg of decomposed cow dung organic fertilizer should be applied per mu, and an appropriate amount of chemical fertilizer should be used. During the flowering and fruiting period, phosphorus and potassium fertilizers can be added, and cow dung organic fertilizer liquid can be sprayed on the leaves to supplement trace elements, which helps to improve the fruit setting rate and fruit quality. For example, during the flowering period of tomatoes, spraying 0.2% - 0.3% cow dung organic fertilizer liquid on the leaves can promote flower bud differentiation and fruit development.

- Root and tuber crops: such as radish and potatoes, have relatively high requirements for phosphorus and potassium, which is conducive to the expansion of roots and tubers. Before planting root and tuber crops, mix cow dung organic fertilizer with the soil thoroughly, and apply about 1500 - 2000 kg per mu. During the root and tuber expansion period, phosphorus and potassium fertilizers and decomposed cow dung organic fertilizer liquid can be applied to promote root and tuber growth. For example, during the potato tuber expansion period, 500 - 800 kg of decomposed cow dung organic fertilizer liquid per mu can be applied to increase potato yield and starch content.

Seasonal Considerations

- Spring: The temperature gradually rises and the soil begins to thaw. It is the season for most crops to be planted. Applying cow dung organic fertilizer at this time can improve soil structure, increase soil fertility, and provide a good soil environment for crop growth. Since the soil humidity in spring is relatively high, you should pay attention to choosing cow dung organic fertilizer with high maturity and moderate water content to avoid affecting the root growth of crops due to heat generated by fertilizer fermentation.

- Summer: The temperature is high, the rainfall is large, and the soil microbial activity is vigorous. When applying cow dung organic fertilizer in summer, you should pay attention to prevent the fertilizer from over-fermenting in a high temperature and high humidity environment, producing harmful gases and high temperature to cause damage to crops. You can use a small amount of fertilization method multiple times, and pay attention to timely covering the soil after fertilization to avoid exposing the fertilizer to the sun. For some vegetables that grow in summer, such as eggplants, peppers, etc., cow dung organic fertilizer can be used in combination with chemical fertilizers during topdressing in summer to meet the nutrient needs of crop growth.

- Autumn: It is the season for crop harvest and an important period for soil nutrient supplementation. Applying cow dung organic fertilizer in autumn can increase the organic matter content of the soil, improve the soil's ability to retain water and fertilizer, and lay the foundation for the growth of crops in the next year. For perennial fruit trees and flowers, applying basal fertilizer in autumn is very critical, and it is generally carried out after the fruit is harvested and before the leaves fall. At this time, the growth of the aboveground parts of fruit trees and flowers gradually slows down, and the root system still has a strong absorption capacity. The application of cow dung organic fertilizer is conducive to the root system to absorb nutrients, accumulate nutrients, enhance the plant's cold resistance, and promote the differentiation and growth of flower buds in the next year.

- Winter: The temperature is low and the activity of soil microorganisms is weakened. In winter, for some crops that hibernate in the open field, such as winter wheat, cow dung organic fertilizer can be applied as wax fertilizer before hibernation to keep warm, retain moisture, and increase soil nutrients. Spreading cow dung organic fertilizer evenly on the surface of the wheat field can form a protective film, reduce soil heat loss, and prevent wheat seedlings from being frozen. At the same time, as the soil temperature slowly rises in winter, cow dung organic fertilizer gradually decomposes to provide nutrients for the growth of wheat seedlings in spring. For facility agriculture, when applying cow dung organic fertilizer in the greenhouse in winter, it is important to control the amount and time of fertilizer application to avoid excessive concentration of harmful gases such as ammonia in the room due to poor ventilation, which may affect crop growth. Fertilizer can be applied in the morning on sunny days, and ventilation can be carried out in time to reduce indoor humidity and harmful gas concentration.

Case Studies and Success Stories

- Case of a farm in Shandong: A large farm in Shandong uses Tongli cow dung organic fertilizer production line products for vegetable planting. The farm composts the collected cow dung and applies it to the tomato planting area. After a comparative test of a planting season, the average height of the tomato field using cow dung organic fertilizer reached 1.5 meters, which was 10-15 cm higher than the control field using ordinary fertilizer. The fruiting rate of tomatoes also increased significantly, with an average of 15-20 fruits per plant, while the average number of fruits per plant in the control field was 12-15. Moreover, the tomatoes grown with cow dung organic fertilizer taste better, the sweetness increased by 2-3 degrees, the price was higher in the market, and the economic benefits were significantly improved.

- Case of a ranch in Inner Mongolia: A ranch in Inner Mongolia mainly raises dairy cows, and cow dung treatment has always been a problem in the past. Later, the ranch introduced a set of Tongli cow dung organic fertilizer production equipment to convert cow dung into organic fertilizer and use it for pasture planting in the ranch. After a period of use, it was found that the growth rate of the grass was significantly accelerated, with an average weekly growth height of 3-4 cm, 1-1.5 cm higher than the area where cow dung organic fertilizer was not used. The protein content of the grass also increased from the original 12%-15% to 15%-18%, effectively improving the milk production and quality of dairy cows. According to statistics, the average daily milk production of dairy cows increased from the original 25-30 liters to 30-35 liters, and the calcium content and milk fat rate in the milk also increased to a certain extent, bringing considerable economic and environmental benefits to the ranch.

Examples from Various Regions

- Northeast China: In some rice-growing areas in Heilongjiang, farmers apply cow dung organic fertilizer to rice fields. Since the soil in Northeast China is fertile but the winter is cold, cow dung organic fertilizer not only provides rich nutrients for rice, but also improves soil structure and enhances soil insulation performance. According to statistics from local agricultural departments, after using cow dung organic fertilizer, the per-acre yield of rice increased from the original 500-550 kg to 550-600 kg, the thousand-grain weight of rice increased by 2-3 grams, and the taste and glossiness of rice also improved significantly, making it more competitive in the market.

- South China: Some orchards in Guangdong use cow dung organic fertilizer to grow fruits such as lychees and longans. The climate in South China is hot and humid, and the soil is highly acidic. The application of cow dung organic fertilizer helps to regulate soil pH and increase soil organic matter content. After years of practice, the fruit setting rate of litchi and longan in orchards using cow dung organic fertilizer has increased by 15% - 20%, the fruit size is uniform, the sweetness has increased by 3 - 5 degrees, and the storage resistance of the fruit has also been enhanced, which has greatly increased the market value of the fruit.

- Northwest region: In some arid areas of Gansu, cow dung organic fertilizer is used for cotton planting. Cow dung organic fertilizer can improve the soil's ability to retain water and fertilizer, reduce water evaporation, and enhance the drought resistance of cotton. According to local growers, after using cow dung organic fertilizer, the height of cotton plants increased by 10 - 15 cm, the number of bolls per plant increased by 2 - 3, and the fiber length of cotton increased from the original 28 - 30 mm to 30 - 32 mm, the quality was significantly improved, and the amount of irrigation water was reduced, achieving the effect of water saving and increased production.

Impact on Crop Yield and Quality

- Improve crop yield: Cow dung organic fertilizer is rich in macronutrients such as nitrogen, phosphorus, potassium, and a variety of trace elements, which can provide comprehensive nutrients for crop growth. For example, in wheat planting, the rational application of cow dung organic fertilizer can increase the number of wheat ears per mu by 10% - 15%, and the number of grains per ear by 5% - 10%, thereby significantly increasing wheat yield. In addition, cow dung organic fertilizer can also improve soil structure, increase soil aeration and water retention, create a good environment for crop root growth, promote root development, and improve the crop's ability to absorb nutrients and water, thereby increasing crop yield.

- Improve crop quality: Cow dung organic fertilizer can improve the quality of agricultural products. Taking apples as an example, apples grown with cow dung organic fertilizer have bright colors, smooth fruit surfaces, sugar content that can be increased by 2 - 4 degrees, vitamin C content that can be increased by 10% - 20%, and taste more delicious. In vegetable planting, cow dung organic fertilizer can reduce the nitrate content in vegetables and improve the safety and nutritional value of vegetables. At the same time, cow dung organic fertilizer can enhance the crops' resistance to diseases and pests, reduce the use of pesticides, make agricultural products greener and more environmentally friendly, and meet consumers' demand for high-quality agricultural products.

Potential Challenges and Considerations

- Changes in raw material properties: The water content and nutrient content of cow dung will vary depending on factors such as the cattle's feed and breeding environment. For example, the water content of cow dung produced by a herd that mainly feeds on silage may be higher, reaching 70% - 80%, which will affect the fermentation process and effect of composting. It is necessary to adjust the moisture to the appropriate range (50% - 60%) by adding dry materials such as rice husks and sawdust.

- Long composting cycle: Cow dung composting usually takes 2 - 3 months or even longer to reach a stable state of maturity. During this process, it is necessary to regularly monitor parameters such as temperature, humidity and oxygen content of the compost to ensure that the fermentation proceeds normally. If the temperature is too high (over 65°C), it may kill beneficial microorganisms, and if it is too low (below 40°C), the fermentation speed will slow down.

- Product quality control: To produce high-quality cow dung organic fertilizer, it is necessary to strictly control the fertilizer's nutrient content, pH value, heavy metal content and other indicators. For example, the total content of nitrogen, phosphorus and potassium in high-quality cow dung organic fertilizer should be above 5%, the pH value should be between 6.5 and 7.5, and the heavy metal content should meet the relevant national standards, otherwise it may cause pollution to the soil and crops.

Handling and Safety Measures

- Material handling safety: In the process of producing cow dung organic fertilizer, a large amount of materials are involved, such as cow dung, straw, etc. When using equipment such as loaders and conveyor belts, operators must strictly abide by the operating procedures to prevent mechanical injury accidents. At the same time, the equipment should be maintained and inspected regularly to ensure its normal operation. For example, the brake system and hydraulic system of the loader should be checked regularly to prevent material falling or equipment loss of control due to failure.

- Dust and noise protection: A large amount of dust and noise will be generated in processes such as crushing and screening. Operators should wear protective equipment such as dust masks and earplugs to protect the respiratory system and hearing. Ventilation and dust removal equipment should be installed in the workshop to reduce the dust concentration. If a bag dust collector is used, the dust concentration in the workshop can be controlled below 10mg/m³, which meets the national occupational health standards. At the same time, sound insulation and shock absorption measures should be taken for equipment with high noise, such as crushers and fans, to control the noise level in the workshop below 85 decibels.

- Fire and explosion prevention measures: During the composting fermentation process, flammable gases such as methane will be generated. Therefore, the composting site should be equipped with good ventilation facilities to prevent the accumulation of flammable gas. At the same time, it is forbidden to carry out open flame operations near the composting site, and fire-fighting equipment such as fire extinguishers and fire hydrants should be equipped and regularly inspected and maintained. In addition, electrical equipment should be explosion-proof to prevent fire or explosion accidents caused by electrical sparks.

Pathogen Management

- High temperature composting kills pathogens: High temperature composting is an effective method to kill pathogens in cow dung. During the composting process, by controlling the temperature, humidity and oxygen content of the pile, the temperature of the pile is raised to 55℃ - 65℃ and maintained for a certain period of time (usually 7 - 10 days), which can effectively kill pathogens such as Escherichia coli, Salmonella, and Ascaris eggs. Studies have shown that under high temperature conditions above 55℃, the mortality rate of Escherichia coli and Salmonella can reach more than 99%, and the mortality rate of Ascaris eggs can also reach more than 95%.

- Pathogen detection and monitoring: Regular pathogen detection of compost raw materials, intermediate products and finished products is an important measure to ensure the quality and safety of cow dung organic fertilizer. Microbial culture, molecular biology and other methods can be used to detect the type and number of pathogens. For example, the number of Escherichia coli groups in each gram of compost product should not exceed 100, and Salmonella should not be detected. Once the pathogens are found to exceed the standard, timely measures should be taken to deal with them, such as extending the composting time, adjusting the composting conditions, or harmlessly treating the products.

- Hygiene management measures: Keeping the production environment clean and hygienic is the key to preventing the spread and breeding of pathogens. Production workshops and composting sites should be cleaned and disinfected regularly, and disinfectants such as bleaching powder and hydrogen peroxide can be used for spraying. At the same time, it is necessary to strengthen the hygiene management of operators, requiring operators to wear work clothes, gloves and masks, etc., to prevent operators from becoming the medium of pathogen transmission.

Odor Control

- Source control: Reasonable adjustment of cattle feed formula can reduce the generation of volatile organic compounds (VOCs) in cattle manure, thereby reducing odor from the source. For example, increasing the digestibility of protein in feed can reduce the emission of malodorous substances such as sulfur compounds. Studies have found that by optimizing the feed formula, the odor intensity of cattle manure can be reduced by 20% - 30%.