What Is Granulated Potash?

Granulated potash, also known as granular potassium fertilizer, granulated potassium chloride, or granulated potassium sulfate, is a widely used chemical fertilizer in agriculture. Its primary components are potassium chloride (KCl) or potassium sulfate (K₂SO₄), typically appearing as white or gray granules. This granular potash fertilizer form provides excellent fluidity, allowing for even distribution during application, and it has high solubility, which promotes efficient plant uptake. Chemically, granular K-fertilizer exhibits strong stability, gradually releasing potassium ions into the soil, ensuring a long-lasting fertilization effect while minimizing volatilization and decomposition.

In agricultural applications, granulated potassium fertilizer plays a crucial role. Potassium is an essential macronutrient for plant growth and development, actively participating in vital physiological processes such as photosynthesis, respiration, carbohydrate metabolism, and nutrient transportation. The appropriate use of granular KCl fertilizer or granulated SOP fertilizer can strengthen plant stems, enhance lodging resistance, and significantly boost both yield and quality. Moreover, potassium-rich fertilizers, such as granulated muriate of potash (MOP) or sulfate of potash (SOP) granules, improve plant resilience against drought, extreme temperatures, and various environmental stresses while enhancing disease and pest resistance.

Granular potassium-based fertilizers offer flexibility in application. They can be used as a base fertilizer before sowing or transplanting, evenly spread over the soil and plowed in; as topdressing during plant growth, applied around the plant and watered for quick dissolution; or, in some cases, as a seed fertilizer, though caution is needed to prevent direct contact between potash granules and seeds to avoid damage. Overall, granulated potash fertilizer holds a vital position in modern agriculture, and its proper application is key to securing high crop yields and sustainable farming.

6 Types of granulated potash

1. Muriate of Potash (MOP) Granules

Muriate of Potash (MOP) Granules are potassium chloride granules, which are one of the most common types of potash fertilizers. The main component is potassium chloride (KCl). Its potassium content is usually high, generally about 60% in terms of potassium oxide (K₂O), which makes it an efficient fertilizer for supplementing potassium. Potassium chloride granules are mostly white or slightly light yellow in appearance, with regular shapes, good fluidity and physical stability, and are easy to store and mechanized fertilization. It is easily soluble in water and can quickly provide potassium nutrition to plants, promote plant photosynthesis, and enhance stress resistance. However, because it contains chloride ions, it may have adverse effects on chlorine-sensitive crops such as tobacco, potatoes, and grapes. It is not suitable for large-scale application, but it has a good effect on chlorine-tolerant crops such as hemp and cotton.

2. Sulfate of Potash (SOP) Granules

Sulfate of Potash (SOP) Granules refers to potassium sulfate granules, which are mainly composed of potassium sulfate (K₂SO₄). Potassium sulfate granules generally contain 50%-54% potassium (measured in K₂O), and also contain about 18% sulfur, which can provide two important nutrients for crops. It often appears as white or light yellow crystalline granules, has low hygroscopicity, is not easy to agglomerate, and has stable chemical properties. Potassium sulfate granules can slowly release potassium ions and sulfate ions in the soil. Potassium ions help plant growth and development, such as promoting fruit enlargement and improving quality, while sulfate ions participate in a variety of physiological processes in plants. They are suitable for all kinds of soils and crops, especially crops that are sensitive to chlorine and crops that require more sulfur, such as onions and garlic vegetables. Using them in acidic soils can also reduce soil acidity and improve the soil environment.

3. Potassium Magnesium Sulfate (K-Mag, Langbeinite) Granules

Potassium Magnesium Sulfate (K - Mag, Langbeinite) Granules also known as potassium magnesium alum granules. It is a multi-element potash fertilizer, the main components of which include potassium, magnesium, and sulfur. It usually contains about 22% potassium (measured in K₂O), about 11% magnesium (MgO), and about 22% sulfur (S). The granules of potassium magnesium sulfate fertilizer are generally white or off-white in appearance, with regular shapes and good physical properties, making them easy to apply fertilizers. Because it provides a variety of essential elements for plants at the same time, it can meet the needs of crops for different nutrients, and is especially suitable for areas where magnesium and sulfur are deficient in the soil. While increasing crop yields, it can also significantly improve the quality of agricultural products, such as improving the sweetness, color and storage resistance of fruits, enhancing the taste of vegetables, etc., and helping to enhance the stress resistance of crops and improve their adaptability to adverse environments such as drought and low temperatures.

4. Nitrate of Potash (NOP) Granules

Nitrate of Potash (NOP) Granules, the main component of which is potassium nitrate (KNO₃). Potassium nitrate granules contain about 13% nitrogen (N) and about 46% potassium (measured in K₂O), and are a nitrogen-potassium binary compound fertilizer. The appearance is mostly colorless, transparent or white crystalline particles, which are easily soluble in water, absorb heat when dissolved, and have relatively stable chemical properties. It can provide plants with two key nutrients, nitrogen and potassium, at the same time. Nitrogen exists in the form of nitrate (NO₃⁻), which can be absorbed and utilized by plant roots without soil microbial conversion, and has rapid fertilizer effect. Potassium nitrate granules are suitable for a variety of crops, especially in the middle and late stages of crop growth, which can promote fruit enlargement, coloring and sweetening, and improve fruit quality. However, because it contains nitrate nitrogen, nitrogen is easily lost when used in paddy fields and other environments prone to denitrification. It is generally more suitable for application in dry land and crops with higher economic value.

5. Granulated Polyhalite

Polyhalite is a natural mineral with the chemical formula K₂Ca₂Mg (SO₄)₄・2H₂O. It contains potassium, calcium, magnesium, sulfur and other elements. It usually contains about 14% potassium (in terms of K₂O), about 17% calcium (CaO), about 4% magnesium (MgO), and about 11% sulfur (S). Granular polyhalite is grayish white or slightly yellow particles with a certain hardness and good physical stability. As a fertilizer, it can supplement the soil with a variety of trace elements, improve soil structure, increase soil fertility, promote balanced growth of plants, and enhance plant resistance to diseases and pests. Because its nutrient release is relatively slow and the fertilizer effect is long-lasting, it can be used as a base fertilizer, especially in areas with poor soil and lack of a variety of trace elements. It can provide a long-term and stable nutrient supply for crop growth and reduce the number of fertilizer applications.

6. Compound Potash Fertilizers (Blended or Complex Fertilizers)

NPK Granulated Fertilizers (Contain potassium along with nitrogen and phosphorus)

- NPK granular fertilizer (containing potassium as well as nitrogen and phosphorus) is a compound fertilizer that combines the three main nutrients required for plant growth - nitrogen (N), phosphorus (P) and potassium (K) in granular form. The potassium element is partly derived from granulated potash fertilizer (Granulated Potash).

- Granulated potash fertilizers are commonly found in potassium chloride, potassium sulfate and other types, which can efficiently provide potassium nutrients to plants. In NPK fertilizers, nitrogen is mainly involved in the synthesis of plant protein and chlorophyll, allowing plants to flourish and have dark green leaves; phosphorus plays a key role in plant root development, flowering and fruiting, and energy conversion; and potassium provided by granular potash fertilizers can enhance plant resistance to stress, such as lodging resistance, drought resistance, disease resistance, etc., and can also improve photosynthesis efficiency and promote carbohydrate transportation and accumulation.

- The ratio of the three elements in NPK granular fertilizers can be adjusted according to the needs of different crops and soils. Common ratios are 15-15-15, 16-16-16, etc. This fertilizer is suitable for a variety of crops and soil types. It can provide comprehensive and balanced nutrients to meet the needs of plants at different growth stages, reduce the number of fertilizations, improve fertilizer utilization, and achieve increased production and quality.

NK or PK Granulated Fertilizers (Combine potassium with nitrogen or phosphorus)

- NK or PK granular fertilizers (combining potassium with nitrogen or phosphorus) are binary compound fertilizers. NK granular fertilizers combine nitrogen and potassium, of which potassium can be provided by granular potassium fertilizers. Nitrogen promotes plant vegetative growth, makes leaves larger and darker green, improves photosynthesis efficiency, and increases biomass; potassium provided by granular potassium fertilizers enhances plant stress resistance, regulates stomatal opening and closing, reduces water loss, and improves water use efficiency.

- PK granular fertilizers combine phosphorus and potassium. Phosphorus is important for plant root development, flower bud differentiation, and fruit development. It can promote early flowering and early fruiting, and improve fruit quality and yield; potassium provided by granular potassium fertilizers plays the aforementioned stress resistance and other roles.

- NK or PK granular fertilizers are suitable for crops that have specific needs for nitrogen and potassium or phosphorus and potassium, or when the soil lacks these two elements. For example, for leafy crops such as spinach and lettuce, NK fertilizers meet their large demands for nitrogen and potassium, promote leaf growth and improve quality; for root crops such as potatoes and sweet potatoes, PK fertilizers help the root system and tubers to expand. Granular potassium fertilizers provide key potassium support for crop growth.

Coated or Slow-Release Potassium Fertilizers (Enhance potassium availability over time)

- Coated or slow-release potassium fertilizers (which increase the effectiveness of potassium over time) are fertilizers that have been processed with special technology to achieve a slow release of potassium. The raw materials used in its production often include granular potassium fertilizers, which are coated with one or more layers of coating materials such as resins, sulfur, polymers, etc. with different water permeability and air permeability on the surface of granular potassium fertilizer particles to control the release rate of potassium ions from the inside of the fertilizer particles into the soil. In this way, potassium can be continuously supplied at different stages of plant growth to meet long-term needs.

- Compared with ordinary potash fertilizers, coated or slow-release potash fertilizers have obvious advantages: they can reduce the fixation and loss of potassium in the soil and improve the utilization rate of potash fertilizers, because the slowly released potassium ions are evenly distributed in the soil, fully contact with the soil colloids, and are not easily replaced and fixed by other ions in the soil; they can avoid the phenomenon of seedling burning caused by excessive fertilization at one time, which is safer for plant growth; they can also reduce the number of fertilizations and reduce labor costs.

- Coated or slow-release potash fertilizers are suitable for all kinds of soils and crops, especially for crops with long growth cycles and stable potassium requirements, such as fruit trees, cotton, and corn. They are effective in continuously providing an appropriate amount of potassium throughout the growing season, helping to increase crop yields and quality and reduce environmental pollution. Among them, granular potash fertilizers are used as the basic raw materials. After coating and other treatments, they play a longer-lasting and stable potassium supply role.

Top 11 Uses for Granulated Potash:

Food

The food industry has a variety of applications for granular potassium fertilizers made from potassium carbonate. In most cases, it is used as a food seasoning to add a unique flavor to the food and stimulate the taste buds of consumers. For example, in some pickled foods, adding a proper amount of granular potassium fertilizer can adjust the flavor and make it taste mellower. In the beer brewing process, granular potassium fertilizer also plays an important role. It participates in the chemical reaction of beer brewing, has a positive effect on the taste and foam stability of beer, and can make beer have better quality. In addition, in history, granular potassium fertilizer (potassium carbonate) has been used in the production of baked goods in Germany. Because its properties are similar to baking soda, when making baked goods such as gingerbread, it can optimize the taste of the recipe, make the gingerbread more crispy, and have a richer aroma, adding a unique charm to traditional baked goods.

Soap

Using potassium hydroxide as the starting material, caustic potash (potassium hydroxide) is an important precursor for the preparation of many "potassium soaps". Compared with soaps made from sodium hydroxide, potassium soaps are softer in texture, but less common in the market. Potassium soaps have outstanding solubility advantages. During the liquefaction process, they require less water than sodium soaps, which makes them more efficiently processed during the soap production process. The use of caustic potash is not limited to the field of soap making. It also plays a key role in the manufacture of detergents and dyes. In detergent production, it helps to improve the detergent's ability to remove stains, especially for some stubborn oil stains. It has a good cleaning effect; in dye manufacturing, it participates in related chemical reactions to help dyes better adhere to materials such as fabrics, improving dyeing effects and color fastness.

Water Softener

Using potassium chloride as a raw material, potassium (potassium chloride) provides an environmentally friendly solution for hard water treatment. Compared with sodium chloride, it performs more efficiently in the process of regenerating ion exchange resins. By using potassium (potassium chloride) to treat hard water, the total amount of chloride emissions in sewage or septic tank systems can be effectively reduced, reducing potential harm to the environment. In some places with high water quality requirements, such as water treatment systems in high-end residential areas, certain water use links in industrial production, etc., using potassium (potassium chloride) as a water softener can not only ensure that the water quality meets the corresponding standards, but also reduce the pressure and cost of subsequent sewage treatment, with good economic and environmental benefits.

Deicing agent (snow melting and ice melting)

With potassium chloride as the main raw material, potassium (potassium chloride) is the core ingredient of deicing agent products. It is often used to remove snow and ice from various surfaces such as roads and building entrances in winter. Compared with other chemicals used for deicing, it has unique advantages. On the one hand, it can quickly and effectively melt ice and snow, ensuring the smooth flow of roads and the safety of pedestrians and vehicles; on the other hand, in the process of melting ice and snow, it can provide fertilizer for grass and other vegetation near the treated surface. As the ice and snow melt, potassium will be integrated into the soil, providing nutrients for vegetation growth, promoting the healthy growth of vegetation, and reducing the damage caused to surrounding vegetation by deicing in winter.

Glass manufacturing

In the glass manufacturing process, glass manufacturers often use granular potassium (potassium carbonate) as a flux. Its main function is to reduce the melting temperature of the glassmaking mixture, which can not only reduce energy consumption and production costs, but also improve production efficiency. Due to the unique properties of potassium, it can give glass excellent transparency, which makes granular potassium indispensable in the manufacture of glass products with extremely high transparency requirements, such as eyeglass lenses, which can give the wearer a clearer vision; glassware, which improves its beauty and texture; TV and computer monitors, which bring users a better visual experience.

Fertilizer

- Plants cannot grow healthily without the three key nutrients of nitrogen, phosphorus and potassium. Granular potash fertilizer is an extremely important member of agricultural fertilizers because it is rich in soluble potassium. Its common raw materials come from a wide range of sources, such as potassium carbonate, potassium chloride, potassium sulfate, etc. Granular potash fertilizer has significant effects in agricultural production. It can optimize the health of plants in all aspects, make the root system stronger, enhance the ability of plants to resist pathogens, and help plants mature smoothly, thereby greatly increasing crop yields. At the same time, it can also significantly improve the appearance and color of agricultural products, making the fruit color more bright and attractive; optimize the texture, making the taste more delicate and delicious, and greatly improving the quality of agricultural products. For example, in orchards, the fruits of fruit trees that apply granular potash fertilizer are larger, brighter in color, and have higher sweetness and juice content.

- Although some potassium elements can be returned to farmland soil by recycling manure and crop residues, most of the key potassium elements still need to be supplemented from the actual needs of agricultural production. At present, there is no efficient potassium supply substitute comparable to potash fertilizer in the commercial field. Therefore, in the agricultural field, granular potash fertilizer has an irreplaceable position. Scientists predict that if there is a lack of fertilizer to increase crop yields, about 33% of the world's regions will face severe food shortages. It can be seen that adding potassium to the soil plays a decisive role in ensuring a sustainable food supply, and granular potash fertilizer can accurately deliver potassium to where plants need it most. In actual application, farmers will choose appropriate granular potash fertilizer products and fertilization methods according to different soil conditions and crop types. For example, in sandy soil, due to poor fertilizer retention, it may be necessary to apply granular potash fertilizer in small amounts and multiple times to ensure that plants continue to obtain sufficient potassium nutrients. 、

Animal feed

In the scope of agricultural use, granular potash fertilizer made from potassium carbonate also has unique applications in animal feed. It can be added to the daily diet of animals as a feed additive to enrich the nutritional content of the feed. When animals ingest feed containing granular potash fertilizer, it can promote the normal growth and development of their bodies and enhance their physical fitness. Not only that, for milk-producing animals, granular potash fertilizer has the additional effect of increasing milk production. For example, in dairy farming, the reasonable addition of this granular potassium fertilizer additive can increase the milk production of dairy cows on the original basis, and the nutritional components in milk such as protein and fat can also remain stable or even increase, improving the quality of milk and the economic benefits of farming.

Aluminum recycling:

Potassium plays a specific role in the aluminum recycling process. Aluminum recycling involves a series of complex processes. The potassium element in granular potash fertilizer can participate in some chemical reactions, which helps to remove impurities from aluminum waste and improve the purity of aluminum, thereby improving the efficiency and quality of aluminum recycling. For example, in some aluminum recycling smelting links, potassium can reduce the surface tension of aluminum liquid and promote the floating separation of impurities, so that the recycled aluminum can better meet the requirements of subsequent processing, providing strong support for the recycling of aluminum resources.

Medicine:

Potassium, as an essential nutrient for the human body, is of great significance in the field of drug manufacturing. Many drugs contain potassium, which is used to maintain normal physiological functions of the human body and treat related diseases. For example, some drugs for the treatment of hypokalemia regulate the body's electrolyte balance by supplementing potassium, and relieve symptoms such as fatigue and arrhythmia caused by low potassium. In some cardiovascular drugs, potassium may also be involved in regulating the normal rhythm of the heart and ensuring heart health.

Magnetic fertilizer: Scientists add magnetic particles to common nitrogen, phosphorus and potassium fertilizers such as granular potash fertilizers to make "magnetic fertilizers". Studies have found that this magnetic fertilizer promotes the photosynthesis of crops. After applying magnetic fertilizer to wheat, wheat yields can increase by 25%, and rice yields can increase by 10%. Using "magnetic fertilizer" on fruit trees such as mandarin oranges not only increases the number of fruits, but also makes them more delicious. The principle is that the process of photosynthesis of chlorophyll in plant leaves under sunlight is related to electromagnetic phenomena. Magnetic fertilizers can affect the electromagnetic properties of chlorophyll, enhance its conductivity, and thus accelerate photosynthesis, promote crop growth and increase yields.

Explosives:

In the field of explosives, potassium is widely used in the production of fireworks, matches and other products. The colorful blooming effect of fireworks and the convenient ignition function of matches are inseparable from the chemical properties of potassium. In the production of fireworks, different potassium compounds are added to the fireworks reagents. They can produce flames of different colors when burning. For example, potassium nitrate can participate in the production of purple flames, bringing people a beautiful visual feast. In the production of matches, potassium compounds such as potassium chlorate are used as oxidants. In combination with other ingredients, they can cause violent reactions under conditions such as friction and achieve ignition.

Magnetic fertilizer:

Scientists add magnetic particles to common nitrogen, phosphorus and potassium fertilizers such as granular potash fertilizers to make "magnetic fertilizers". Studies have found that this magnetic fertilizer promotes the photosynthesis of crops. After applying magnetic fertilizer to wheat, wheat yields can increase by 25%, and rice yields can increase by 10%. Using "magnetic fertilizer" on fruit trees such as mandarin oranges not only increases the number of fruits, but also makes them more delicious. The principle is that the process of photosynthesis of chlorophyll in plant leaves under sunlight is related to electromagnetic phenomena. Magnetic fertilizers can affect the electromagnetic properties of chlorophyll, enhance its conductivity, and thus accelerate photosynthesis, promote crop growth and increase yields.

Production Processes of Granulated Potash

Mining and Extraction

- In the production process of granular potash fertilizer, mining and extraction are the key initial links. Potash mining methods mainly include underground mining, open-pit mining and solution mining. Underground mining is suitable for potash mines with a burial depth of more than 100 meters. In many potash mines in Saskatchewan, Canada, room-and-pillar mining is mostly used.

- During underground operations, a series of structures similar to "rooms" and "pillars" are excavated. The "rooms" are used to mine ore, while the "pillars" are responsible for supporting the roof to ensure safety during the mining process. The ore recovery rate of this mining method is roughly in the range of 60%-70%, and it can effectively mine potash layers with a thickness of 3-10 meters.

- Open-pit mining is mainly aimed at shallow potash mines. Taking some potash mines in Germany as an example, this method has the advantage of relatively low mining costs, can operate large areas of potash mines with suitable thickness, and has extremely high mining efficiency. The daily mining volume can reach tens of thousands of tons. However, open-pit mining is more damaging to the surface environment. Solution mining is to inject fresh water or brine into the underground potash layer to dissolve the potash salt and then extract the potassium-containing solution. Some potash mines in New Mexico, USA, use this method. Solution mining has less disturbance to the environment and is particularly suitable for mining low-grade, deeply buried potash ores that are difficult to mine by conventional means. However, the potassium concentration in the solution extracted by this method is low, and the difficulty and cost of subsequent refining work will increase accordingly. Generally speaking, the potassium content of the extracted solution is about 1%-5%.

Overview of potash mining methods

- After the potash ore is mined, the refining and processing links are carried out in full swing. From potash ore to the final granular potash fertilizer, it takes many complex processes. Taking the common potassium chloride type potash ore as an example, it will first be crushed and ground to crush the mined large pieces of potash ore to a suitable particle size, and then ground into fine powder for subsequent separation operations. Then, the dissolution crystallization method is used to put the ground potash ore into a specific solution, and the potassium salt is dissolved by controlling the temperature, concentration and other conditions, and then the potassium chloride crystals are precipitated through evaporation concentration, cooling crystallization and other steps. In this process, the control of temperature and solution concentration is extremely critical.

- For example, in the evaporation concentration stage, the solution temperature is usually controlled between 80℃-100℃ to ensure evaporation efficiency and avoid impurity crystallization. The obtained potassium chloride crystals are washed and filtered many times to remove impurities and improve purity. After that, in order to make granular potash fertilizer, granulation technology is used, and the common ones are disc granulation and drum granulation.

- During disc granulation, potassium chloride crystals and appropriate amounts of additives, binders, etc. are placed in a rotating disc. By spraying water or other means, the materials are rolled and agglomerated into particles in the disc. The disc speed is generally controlled at 15-30 rpm to ensure uniform particle size.

- Drum granulation is to complete the agglomeration and granulation of materials in a drum. The inclination angle and speed of the drum will affect the quality of granular potassium fertilizer. Generally, the inclination angle is 3°-5° and the speed is 10-20 rpm. After granulation, the granular potassium fertilizer needs to be screened to remove unqualified large particles and fine powder, and finally obtain a product that meets the standards.

Key global production regions

- From a global perspective, potash production is highly concentrated, with the main production areas distributed in Canada, Russia and Belarus. Canada has a dominant position in the global potash production field due to its extremely rich potash reserves and advanced mining technology, and is firmly seated on the throne of the world's largest potash producer. In 2023 alone, Canada's potash production accounted for about 38% of the world's total production. Its potash resources are mainly concentrated in Saskatchewan, where potash reserves account for about 25% of the world's total. In Saskatchewan, there are many large potash mining companies, whose annual production capacity can reach tens of millions of tons. Russia is also an important potash producer in the world, accounting for about 20% of the world's total.

- Russia's main potash producing areas are located in the Ural region and East Siberia. The potash mines in these areas have the significant characteristics of thick ore layers and high grades, and the potassium content of some ore layers even exceeds 20%. Russia uses a variety of mining methods in the process of potash mining to achieve efficient output of potash ore. Belarus also occupies an important position in global potash production, accounting for about 17% of the world's total output.

- The potash resources in Belarus are not only abundant, but also easy to mine. Through continuous optimization of mining and processing technology, the scale of potash production in Belarus is constantly expanding, and the quality of the granular potash fertilizer products produced is stable, and a large number of products are exported to all parts of the world.

Potash Granulation Techniques

Disc Pan granulation process

- Disc granulation is one of the more common technologies. In the disc granulation process, basic materials containing potassium salts, such as potassium chloride, potassium sulfate, etc., are mixed with additives, binders, etc. in a certain proportion and sent into a high-speed rotating disc.

- The disc rotates continuously at a speed of 15 to 30 revolutions per minute, and water is sprayed evenly into the disc. Under the combined action of centrifugal force, friction and gravity, the materials continue to roll and agglomerate in the disc. Smaller particles will gradually absorb the surrounding materials and slowly grow like a snowball, eventually forming granular potassium fertilizers that meet the particle size requirements.

- The advantages of disc granulation are that the equipment has a simple structure and is easy to operate. It can flexibly adjust the size and shape of the particles. The particles produced have good roundness and a relatively concentrated particle size distribution. Usually, more than 80% of the products can be controlled within the ideal particle size range of 2 to 4 mm, which is conducive to the dispersion and dissolution of fertilizers in the soil and improves the efficiency of nutrient release. This technology is applicable to a variety of potassium salt raw materials. Whether it is a single potassium salt or a compound potassium salt formula, it can achieve good granulation effects and is widely used in small and medium-sized potassium fertilizer production enterprises.

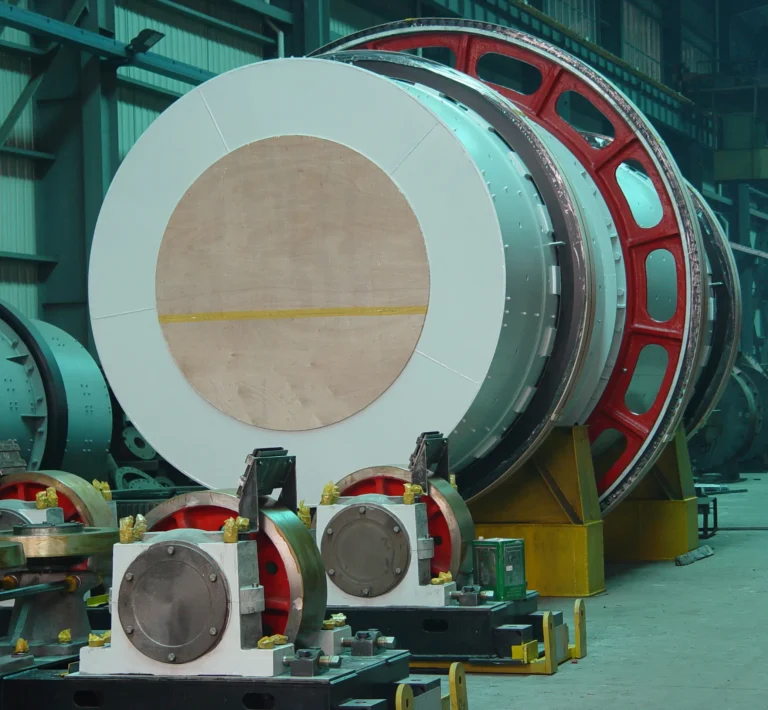

Drum Agglomeration

- Drum granulation technology is also widely used. The drum granulation equipment mainly consists of a tilted and continuously rotating drum, with the tilt angle generally maintained at 3° to 5°. The mixture containing potassium salt enters from the high end of the drum. During the rotation of the drum at a speed of 10 to 20 revolutions per minute, the material slowly moves along the axial direction of the drum while rolling inside the drum. At the same time, the binder solution is sprayed on the material through the nozzle to make the material adhere to each other and agglomerate into particles.

- Drum granulation can handle larger-scale materials with high production efficiency. Its production capacity can generally reach several tons to tens of tons per hour. Moreover, the granular potassium fertilizer particles produced by this technology have good strength and are not easy to break during storage and transportation, which is crucial for fertilizer products that are transported over long distances and stored for a long time. Since drum granulation causes relatively little wear and tear on the equipment and has low maintenance costs, it is quite popular among large-scale potassium fertilizer production enterprises, especially suitable for large-scale industrial production.

Spray granulation

- Spray granulation is a relatively complex but efficient granulation technology. The technology first makes the potassium salt raw material and other additives into a slurry with good fluidity. The concentration of the slurry is usually controlled between 60% and 75% to ensure that it has suitable spraying performance.

- The slurry is sprayed into the granulation tower through a high-pressure nozzle. In the granulation tower, hot air flows upward from the bottom and contacts the slurry sprayed from top to bottom in countercurrent. The slurry evaporates water rapidly under the action of hot air, and the droplets gradually solidify to form particles. The granular potassium fertilizer particles produced by spray granulation are relatively uniform in size, spherical, and have a large specific surface area, which allows the fertilizer to dissolve quickly in the soil, release nutrients quickly, and meet the crop's demand for potassium in a timely manner.

- The production process of spray granulation has a high degree of automation, can achieve continuous production, and has a large production capacity. The annual output of some large-scale spray granulation devices can reach hundreds of thousands of tons. However, this technology has high requirements for equipment, large investment costs, and relatively high energy consumption. It is generally suitable for large-scale potassium fertilizer production enterprises with strong funds and the pursuit of high yields and high-quality products.

Compaction granulation process

- Extrusion granulation technology uses mechanical pressure to extrude pretreated potassium salt materials into particles of a specific shape. First, the potassium salt raw materials are pretreated by crushing and mixing to make their particle size and composition uniform. Then, the material is fed into the extruder. Under the strong pressure of the extruder, the material is extruded through the specific orifice plate of the mold to form a strip-shaped material. These strip materials are then cut into particles of a certain length by a subsequent cutting device.

- The granular potassium fertilizer particles produced by extrusion granulation have high density and strength, good wear resistance and crushing resistance, and excellent stability during storage and transportation. Moreover, this technology has strong adaptability to materials and can handle some potassium salt materials that are more viscous or difficult to form by other granulation methods.

- The extrusion granulation equipment occupies a relatively small area, has a relatively simple production process, and has relatively low energy consumption. It is suitable for potassium fertilizer production scenarios with moderate production scale and high requirements for particle strength. It has unique advantages in the production of some special formulas or special granular potassium fertilizer products.

Benefits of Using Granulated Potash in Agriculture

Enhanced Nutrient UptakeImprovement in root development

Increased resistance to diseases and pests:

Granular potassium fertilizer is effective in enhancing plant resistance to diseases and pests. Potassium can enhance the strength and toughness of plant cell walls, making it difficult for pathogens to invade plant cells. When the potassium content in plants is sufficient, some disease-resistant substances synthesized by plants, such as lignin and phytoalexin, will increase.

Studies have found that in tomato cultivation, the lignin content in the leaves and fruits of tomato plants that were fertilized with granular potassium fertilizer increased by 15%-20% compared with plants that were not fertilized with potassium, and the incidence of common diseases such as leaf mold and early blight was reduced by 25%-35%. At the same time, potassium can also regulate plant metabolism, causing plants to produce certain volatile substances, which have a repellent effect on pests.

For example, in cotton cultivation, the population density of cotton bollworms in cotton fields that were properly fertilized with granular potassium fertilizer was 20%-30% lower than that in cotton fields that were not fertilized with potassium, which effectively reduced the damage of pests to cotton and ensured the yield and quality of cotton.

Improved Crop Yield and Quality

Impact on fruit and flower production

- In terms of fruit production, granular potassium fertilizer has a very prominent effect on improving fruit yield and quality. Potassium is one of the essential macronutrients for plant growth and can effectively promote plant photosynthesis. Studies have shown that after applying granular potassium fertilizer, the photosynthetic efficiency of fruit trees can be increased by 15%-25%.

- Adequate photosynthetic products provide a rich material basis for fruit enlargement and can significantly increase the size and weight of fruits. For example, in apple planting, in orchards where granular potassium fertilizer is reasonably applied, the weight of a single apple can increase by 10%-20% compared with orchards that do not apply it, the horizontal diameter of the fruit increases by 5%-10%, and the yield increases by 15%-30%. Moreover, potassium participates in the metabolism and transportation of carbohydrates in plants, helps accumulate sugars, and improves the taste of fruits. Relevant data show that after using granular potassium fertilizer, the sweetness of grapes can be increased by 1-2 degrees, and the soluble solids content of strawberries can be increased by 1.5%-3%, making the fruit taste sweeter and more delicious.

- In flower production, granular potassium fertilizer has a significant effect on the growth and ornamental value of flowers. Potassium can promote the development of flower roots, make the root system more robust and developed, and enhance the ability of flowers to absorb nutrients and water. It has been observed that the root volume of flowers applied with granular potassium fertilizer can increase by 20%-30% compared with those without potassium application, and the root vitality can increase by 15%-20%. This provides a solid guarantee for the growth of the above-ground part of flowers, making flower plants stronger and the number of flowers more abundant. For example, in rose cultivation, the number of rose flowers treated with potassium increased by 10%-15% compared to those without potassium.

Enhancement of taste, color, and texture

Granular potassium fertilizer also contributes to the appearance and color of fruits. Potassium can promote the synthesis and accumulation of pigments in fruits. Taking citrus as an example, after applying granular potassium fertilizer, the coloring area of citrus fruits increased by 20%-30% compared with orchards without application, the color became brighter, the skin became smoother, the appearance of the fruit became more attractive, and it was easier to be favored by consumers in the market. For some fruits with thin peels, such as cherries, potassium can also enhance the toughness of the peel, reduce the phenomenon of fruit cracking, and increase the commercial rate of the fruit. Studies have shown that reasonable potassium application can reduce the cherry fruit cracking rate by 15%-25%.

Granular potassium fertilizer has a significant effect on improving the color and texture of flowers. Potassium helps the synthesis of pigments such as anthocyanins, making the colors of flowers more vivid and rich. In tulip cultivation, after applying granular potassium fertilizer, the saturation of red, purple and other colors of tulip flowers increased by 15%-20%, and the ornamental value was greatly improved. Moreover, potassium can make the petals of flowers thicker and tougher, and extend the shelf life of flowers. Studies have found that after applying granular potassium fertilizer to carnations, the thickness of petals increased by 10%-15%, and the vase life was extended by 2-3 days, which reduced the loss of flowers during transportation and sales and improved economic benefits.

Soil Health and Sustainability

Role in maintaining soil fertility

Granular potassium fertilizer is essential for maintaining soil fertility. Potassium is a macronutrient essential for plant growth. It can enhance soil microbial activity and increase the activity of nitrification and denitrification bacteria involved in nitrogen conversion by 20%-30%, promote nitrogen cycle, and help improve soil fertility. Different types of granular potassium fertilizers have different effects on soil pH. Potassium sulfate can prevent further acidification of acidic soils and maintain a pH value suitable for crop growth (6.0-7.5). Potassium ions can also cause soil particles to condense into a granular structure. Long-term application can increase the stability of the granular structure by 15%-20%, improve soil ventilation, water permeability, and fertilizer and water retention.

Environmental considerations

From an environmental perspective, the rational use of granular potassium fertilizers has many benefits. Potassium deficiency in the soil will lead to poor plant growth, and farmers are prone to excessive nitrogen fertilizer application, resulting in nitrogen loss and eutrophication of water bodies. Reasonable supplementation of granular potassium fertilizers can increase the utilization rate of nitrogen fertilizers by 10%-15% and reduce the risk of nitrogen pollution. Moreover, potassium enhances plant resistance to stress. In arid areas, applying granular potassium fertilizer can increase crop water use efficiency by 18%-25%, reducing irrigation water. At the same time, it can enhance crop resistance to diseases and insect pests, reduce pesticide use, and benefit ecological environment protection.

Application Guidelines for Granulated Potash

Determining Application Rates

Soil testing and analysis

- Soil testing and analysis is the first step in the rational application of granular potassium fertilizer. Generally, chemical extraction is used to extract potassium from the soil with a specific extractant (such as ammonium acetate solution), and then its content is measured with the help of instruments such as flame photometers. Soil potassium is divided into fast-acting potassium, slow-acting potassium and mineral potassium. Among them, fast-acting potassium can be directly absorbed by crops and is a key indicator of soil potassium supply capacity.

- Generally, when the soil fast-acting potassium content is lower than 80mg/kg, it is considered to be potassium-deficient and granular potassium fertilizer needs to be supplemented in time; when the content is between 80-120mg/kg, it is in the potential potassium deficiency range, and whether to apply fertilizer should be determined based on crop needs and other soil conditions; when it is higher than 120mg/kg, the soil potassium supply is relatively sufficient.

- In addition to potassium content, soil pH, texture, etc. will also affect the effectiveness of potassium. In acidic soil, potassium ions are easily leached, so the application amount of granular potassium fertilizer needs to be appropriately increased; sandy soil has poor fertilizer retention capacity and potassium is easily lost, so the frequency of fertilization and the single amount need to be reasonably adjusted; clay soil is the opposite, it has good fertilizer retention capacity, but the potassium release is slow in the early stage, so it is appropriate to apply fertilizer in advance.

Recommended dosages for various crops

- The recommended dosage of granular potassium fertilizer varies significantly for different crops. Taking common field crops as an example, corn is a potassium-loving crop. In potassium-deficient soil, 150-225kg of potassium chloride (containing about 60% potassium in terms of K₂O) can be applied per hectare as basal fertilizer, and 100-150kg can be applied as topdressing during the large bell mouth stage. This can significantly improve the strength of corn stalks, reduce lodging, increase grain fullness, and increase yield by 10%-20%. For wheat in soil with average fertility, 8-10kg of potassium sulfate (containing about 50% K₂O) per mu as basal fertilizer, and 3-5kg can be applied during the jointing stage. This helps the development of wheat roots, enhances cold and drought resistance, promotes tillering and grain filling, increases protein content, and optimizes quality.

- As for cash crops, cotton has a high demand for potassium. In soils with medium to low potassium content, 10-15kg of potassium sulfate is used as base fertilizer per mu, and 15-20kg is applied during the flowering and bolling period. This can enhance cotton stress resistance, reduce the occurrence of red leaf stem blight, increase cotton fiber length and strength, increase boll weight, and increase yield by about 15%.

- Among vegetables, in soils lacking potassium, 10-12kg of potassium sulfate is applied as base fertilizer per mu for cucumbers, and 2-3kg is applied every 7-10 days during the fruiting period. This can promote the robustness of cucumber plants, increase fruit setting rate, improve fruit taste and appearance, and extend the picking period. For fruit trees such as apple trees, 0.5-1kg of potassium sulfate is applied per plant before budding in spring, and about 0.5kg is applied during the fruit expansion period. This can improve the color, sweetness and storage resistance of apples, enhance the tree's stress resistance, and reduce the occurrence of diseases.

Methods of Application

Broadcasting vs. banding techniques

- In terms of fertilization technology, broadcasting and banding techniques are two common methods. Broadcasting is to spread granular potassium fertilizer evenly on the soil surface and then mix it into the soil through plowing and other methods. This method is easy to operate and is suitable for large areas of farmland with relatively uniform soil fertility.

- For example, in plain areas where wheat is grown on a large scale, broadcasting is often used. However, broadcasting has the problem of relatively low fertilizer utilization rate, because the fertilizer is more dispersed in the soil, and some potassium elements may not be effectively absorbed and utilized by the crop roots. According to research, the utilization rate of granular potassium fertilizer in the current season under broadcasting is about 30% - 35%.

- Banding is to concentrate granular potassium fertilizer on the crop sowing row or one side of the plant to form a narrow fertilization belt, generally 5 - 10 cm away from the seeds or plants, and about 8 - 15 cm deep. This method can bring the fertilizer closer to the crop roots and improve the root absorption efficiency of potassium elements.

- Taking corn planting as an example, strip application of granular potassium fertilizer can make the potassium ion concentration around the corn root system 2-3 times higher than that of broadcast application, and the fertilizer utilization rate can be increased to 40%-45%. Especially in soils with uneven fertility or where potassium is easily fixed, the advantages of strip application are more obvious, allowing limited fertilizers to play a greater role, promoting crop growth and increasing yields.

Timing and frequency of application

Timing

- For annual crops, such as rice, a certain amount of granular potassium fertilizer should be applied at the basal stage, generally accounting for 50% - 60% of the total potassium application, to provide sufficient potassium for the early growth of rice and promote root development and tillering.

- During the rice heading stage, which is a critical period for potassium demand, applying 30% - 40% of the remaining potassium can enhance the rice's resistance to lodging and increase the fruiting rate.

- If the soil potassium content is low, a small amount of granular potassium fertilizer can be appropriately applied during the filling period, accounting for about 10% - 20% of the total potassium application, to ensure the supply of nutrients in the later period and improve the quality of rice.

Frequency

- For perennial crops such as apple trees, granular potassium fertilizer should be applied as basal fertilizer in time after fruit harvest in autumn. At this time, the root system is at its peak growth period, which can effectively absorb potassium, store nutrients, and enhance the tree's cold resistance. The amount of potassium applied as basal fertilizer accounts for about 60% - 70% of the whole year.

- Topdressing should be carried out before budding in spring and during the fruit expansion period, and the amount of topdressing each time accounts for about 15% - 20% of the whole year. Topdressing before budding promotes the growth of new shoots and leaf development, and topdressing during the fruit expansion period helps to increase the fruit size and sugar content.

- If the timing of fertilization is inappropriate, such as missing fertilization during the peak period of crop potassium demand, crop growth will be hindered and yield will be reduced. For example, if cotton lacks potassium during the flowering and bolling period, the bud and boll shedding rate can increase by 20% - 30%. The frequency of fertilization should not be too high or too low. Too high a frequency can easily cause fertilizer waste and environmental pollution, while too low a frequency cannot meet the continuous demand for potassium for crop growth.

Safety and Handling Precautions

Proper storage practices

- In terms of storage, granular potassium fertilizer should be stored in a dry and well-ventilated warehouse. The relative humidity of the warehouse needs to be strictly controlled below 65%, because the main components of granular potassium fertilizer, such as potassium chloride and potassium sulfate, have certain hygroscopicity. Once the relative humidity is higher than 65%, the fertilizer particles are easy to absorb moisture in the air and clump.

- For example, in the southern region with high humidity, if the humidity management of the warehouse is not good, the fertilizer caking rate may be as high as 30% - 40% after 1 month of storage. The caking not only affects the normal application of the fertilizer, but also reduces its fertilizer efficiency. At the same time, the warehouse temperature should be kept between 10℃ - 30℃. If the temperature is too high, it may accelerate the chemical reaction of certain components in the fertilizer and cause nutrient loss; if the temperature is too low, especially below 0℃, some potassium salts containing crystal water may undergo crystal transformation, which also affects the fertilizer efficiency.

- The warehouse floor should be treated with moisture-proof treatment and raised by 20 - 30 cm to prevent the fertilizer from directly contacting the ground and prevent moisture. The height of fertilizer stacking should not exceed 2 meters. If it is too high, it will easily cause the bottom fertilizer to be compressed and agglomerated, and there will be safety hazards.

Protective equipment and procedures

- During the operation, protective equipment must be equipped and used correctly. Operators should wear protective gloves, generally chemical-resistant nitrile gloves, which can effectively block direct contact between fertilizer and skin, and prevent skin irritation and corrosion due to contact with alkaline substances or other chemical components in fertilizer.

- According to relevant statistics, if you engage in operations such as handling granular potassium fertilizer for 1 hour without wearing gloves, the probability of hand skin allergies or minor burns is as high as 20% - 30%. At the same time, wear protective glasses to prevent fertilizer particles from splashing into the eyes and causing eye damage. If fertilizer particles accidentally enter the eyes, rinse immediately with plenty of water for 15 - 20 minutes and seek medical attention in time. Protective clothing should also be worn during operation. The material of the protective clothing should have good breathability and chemical corrosion resistance to protect the body from fertilizer erosion.

- In addition, when working in a poorly ventilated environment, wear a dust mask and choose a KN95 or higher grade mask with a filtration efficiency of at least 95%, because granular potash fertilizers will generate dust during transportation and loading and unloading, and long-term inhalation may cause respiratory diseases. For example, in a working environment with high dust concentration, if you work for 1 month without wearing a suitable mask, the risk of respiratory diseases will increase by 5-10 times compared to a normal environment. After the operation, be sure to clean the contact parts of the body and change clothes in time to avoid residual fertilizers causing continuous damage to the body.

Granulated Potash vs. Other Potassium Fertilizers

Comparison with Muriate of Potash (MOP)

Chloride content considerations

Granular pot ash fertilizers and Muriate of Potash (MOP) differ in many aspects. First of all, in terms of chloride content, potassium chloride has a very high chloride content. For example, the chloride content (in terms of chlorine element) of common agricultural potassium chloride fertilizers can usually reach 45% - 60%. Granular potash fertilizers, if they are potassium sulfate-type granular potash fertilizers, basically do not contain chlorine elements;

If they are chlorine-containing granular potash fertilizers, their chloride content is also significantly lower than that of potassium chloride, generally around 5% - 15%, and the specific value depends on the production process and formula. After potassium chloride with a high chloride content dissolves in the soil, a large amount of chloride ions will remain in the soil. With long-term and large-scale application, the chloride ion concentration in the soil will gradually increase, changing the chemical properties of the soil, especially in some poorly drained soils, where chloride ions are easy to accumulate, which may lead to increased soil salinization.

Crop sensitivity factors

- Crops also have very different sensitivities to the two. Many crops are sensitive to chloride ions. For example, if potassium chloride with a high chloride content is applied to tobacco, the chloride content in the tobacco leaves will increase. When the chloride content of tobacco leaves exceeds 1%, the combustibility of the tobacco leaves will be reduced, causing the tobacco leaves to extinguish when burning, seriously affecting the quality of tobacco;

- Potatoes are also very sensitive to chloride ions. Chloride ions interfere with starch synthesis in potato plants, resulting in a decrease in tuber starch content. Generally speaking, when the chloride ion concentration in the soil is too high, the starch content of potato tubers may decrease by 5% - 10%, affecting its taste and processing quality.

- Grapes are also sensitive to chlorine. Excessive chloride ions will affect the sugar accumulation and flavor of grape fruits, making the fruit taste worse and the sweetness lower. In contrast, potassium sulfate products in granular potash fertilizers are more friendly to these chlorine-sensitive crops because they do not contain chloride ions. They can meet their needs for potassium while avoiding the negative effects of chloride ions, ensuring the normal growth of crops and the quality of agricultural products.

Comparison with Sulfate of Potash (SOP)

Sulfur content benefits

From the perspective of the benefits of sulfur content, potassium sulfate itself is a sulfur-containing potash fertilizer with a considerable sulfur content. Generally speaking, the sulfur (S) content in agricultural potassium sulfate fertilizer is about 17% - 18%. Sulfur is of great significance to plant growth. It participates in the synthesis of proteins, amino acids and some enzymes in plants. In the growth process of cruciferous crops such as rapeseed and radish, sufficient sulfur supply can promote plants to synthesize protein better, enhance the cold and drought resistance of crops, and increase crop yields. Studies have shown that when rapeseed is planted in sulfur-deficient soil and sulfur-containing potassium sulfate fertilizer is applied, the rapeseed yield can be increased by 10% - 15% compared with no sulfur fertilizer. In addition, sulfur can also improve the quality of agricultural products, such as making garlic, onions and other crops more flavorful. Granular potash fertilizer, if it is potassium sulfate type granular potash fertilizer, also has these benefits brought by sulfur; if it is other types of granular potash fertilizer, such as potassium chloride type granular potash fertilizer, it basically does not contain sulfur, and there is a lack of sulfur nutrients for plants.

Cost and availability

- In terms of cost and availability, the production cost of potassium sulfate is relatively high. This is mainly because the production process of potassium sulfate is relatively complicated. Whether it is extracted from natural minerals or produced through potassium chloride conversion, it involves multiple processes.

- Taking the potassium chloride conversion method to produce potassium sulfate as an example, sulfuric acid and other raw materials are required for reaction, and the reaction process requires precise control of temperature, pH and other conditions, which increases the production cost of potassium sulfate. In the market, the price of potassium sulfate is usually 20% - 30% higher than that of ordinary granular potash fertilizers (such as potassium chloride granular potash fertilizers). In terms of availability, the global distribution of potassium sulfate resources is relatively limited, and its main producing countries are concentrated in a few regions, which leads to certain fluctuations in the supply of potassium sulfate in some regions, especially in the peak season of agricultural demand, and there may be a shortage of supply.

- In contrast, granular potash fertilizers are diverse, covering potassium chloride type, potassium sulfate type and other types, and potassium chloride type granular potash fertilizers are rich in resources and have a relatively simple production process. Its global output is large, and its supply in the market is more stable and extensive, which can better meet the demand for potash fertilizers in agricultural production in different regions.

Market Trends and Future Outlook

Innovations in Potash Fertilizer Technology

Advances in granulation processes

- Granular potassium fertilizer produced by traditional granulation technology has problems such as poor particle uniformity and insufficient strength. It is easy to break and agglomerate during storage and transportation, which affects the fertilization effect.

- In recent years, fluidized granulation technology has made major breakthroughs. This technology uses gas to fluidize the potassium fertilizer raw materials. On the fluidized bed, the binder is sprayed by a precisely controlled spray device to allow the fertilizer particles to agglomerate uniformly in a dynamic environment.

- Compared with traditional disc granulation, the granular potassium fertilizer produced by fluidized granulation has a more regular shape, the coefficient of variation of particle size can be reduced to less than 5% (traditional disc granulation is about 10%-15%), and the particle strength is increased by 30%-40%, which greatly reduces the loss during storage and transportation.

- At the same time, spray drying granulation technology is also constantly innovating. After the concentrated potassium fertilizer solution is atomized by a special nozzle, it is instantly dried into particles in a hot air flow. This technology can precisely control the chemical composition and physical properties of the particles. For example, the purity of the potassium sulfate-type granular potash fertilizer produced can be stabilized at more than 98%. The particle surface is smooth and has excellent fluidity, which is conducive to mechanized fertilization. The fertilization efficiency is about 20% higher than that of ordinary granular potash fertilizer.

Development of enhanced efficiency fertilizers

The advent of slow-release potassium fertilizer is a major innovation. It achieves the slow release of potassium by coating the surface of fertilizer particles with special coating materials, such as resin and sulfur. Taking resin-coated slow-release potassium fertilizer as an example, in the soil, according to the potassium requirements of crops at different growth stages, the potassium release cycle can be accurately controlled for up to 60-90 days, which can continuously and stably supply potassium to crops, and the fertilizer utilization rate is greatly increased from 30%-35% of ordinary potassium fertilizer to 50%-60%.

Frequently Asked Questions (FAQs)

From the perspective of form, most common potassium sources such as wood ash are in powder form, while potash ore is in block form or has large and irregular particles, while granular potash fertilizer is processed and specially made into uniform particles. This regular particle gives it good fluidity, and during the fertilization process, it can be spread more accurately and evenly with the help of mechanized equipment. Compared with powdered wood ash, it can increase the fertilization efficiency by about 30% - 40%, greatly saving manpower and time costs.

In terms of ingredients, potassium magnesium sulfate fertilizer contains various elements such as magnesium (MgO about 11%) and sulfur (S about 22%) in addition to potassium (generally containing about 22% potassium (in terms of K₂O); potassium nitrate contains nitrogen (N about 13%) and potassium (in terms of K₂O about 46%). The potassium content (in K₂O) of common granular potassium chloride fertilizers is usually as high as about 60%, and the potassium content (in K₂O) of potassium sulfate granular potassium fertilizers is between 50% and 54%. Granular potassium fertilizers have relatively simple ingredients and focus on efficient potassium supplementation. They can quickly supplement a large amount of potassium for extremely potassium-deficient soils or crops with strong potassium demand.

In terms of solubility, some potassium sources, such as potassium feldspar, are insoluble potassium ores, and it is difficult to release potassium ions for plant absorption under natural conditions. Granular potassium fertilizers have better solubility. For example, the solubility of granular potassium chloride at 20°C is 34.7g/100g water. It can dissolve quickly in soil solution and provide absorbable potassium ions to plant roots in a short time, with rapid fertilizer effect. In contrast, insoluble potassium sources may take months or even years to slowly release a small amount of potassium, which cannot meet the urgent demand for potassium in the rapid growth stage of crops.

The fertilizer effect characteristics are also different. The potassium element in organic fertilizer needs to be decomposed and transformed by soil microorganisms for a long time before it can be absorbed and utilized by plants. This process is relatively slow and is affected by many factors such as soil temperature, humidity, and microbial species. Granular potassium fertilizer has a fast and controllable fertilizer effect. For some crops with a short growth cycle and a clear potassium critical period, such as vegetables, applying granular potassium fertilizer before their potassium peak period can meet growth needs in time and significantly improve yield and quality. In vegetable planting experiments, the plots where granular potassium fertilizer was applied during the critical period can increase vegetable yields by 20% - 30% compared with plots where granular potassium fertilizer was not applied.

There are also differences in applicable scenarios. Some industrial byproduct potassium sources may contain harmful substances such as heavy metals and are not suitable for the cultivation of edible agricultural products. Granular potassium fertilizer is highly safe and widely used in the cultivation of various crops. Whether it is food crops such as rice and wheat, or cash crops such as cotton and tobacco, the reasonable application of granular potassium fertilizer can improve growth conditions, improve stress resistance, and increase yield.

In terms of appearance, the leaves of plants usually change. First, the tips and edges of old leaves begin to turn yellow and gradually turn brown, just like being burned by fire. This phenomenon is called "burnt edge". Take corn as an example. When potassium is deficient, the tips and edges of the lower old leaves will first turn yellow. As the degree of potassium deficiency increases, the yellowing area will gradually expand to the middle of the leaf. In severe cases, the entire leaf will dry up and die. According to statistics, the yellowing area of corn leaves grown in soil with severe potassium deficiency can reach more than 50% of the total leaf area.

The growth rate of plants will also be significantly affected. Potassium deficiency can cause plants to grow slowly and be short. For example, in a study of tomatoes, it was found that compared with tomato plants with normal potassium supply, the height of potassium-deficient plants may decrease by 20%-30% in the later growth period, the stems are thin and weak, and the ability to resist lodging is significantly reduced. This is because potassium is involved in the synthesis of cellulose and lignin in plant cell walls. Potassium deficiency can make the cell walls thinner and the cell support is insufficient, thus affecting the overall morphology and growth potential of the plant.

In addition, the root development of plants will also be hindered. When potassium is deficient, the root system of plants grows poorly, the root vitality is reduced, and the elongation of roots and the formation of lateral roots are inhibited. Taking rice as an example, the root color of potassium-deficient rice will become darker, dark brown, the root volume will decrease, the root distribution will be shallow, and the ability to absorb water and nutrients will be weakened. Studies have shown that the dry weight of the root system of potassium-deficient rice can be reduced by 15%-20% compared with normal plants, which further affects the growth and development of the aboveground part of the plant, forming a vicious circle.

At the same time, the development of fruits and seeds of plants will also be affected. Potassium deficiency will cause the fruit to become smaller, deformed, and the quality will decrease. For example, when apples are deficient in potassium, the fruit color is poor, the sugar content is reduced, the fruit hardness is reduced, and it is not resistant to storage. In some orchards, the weight of a single fruit produced by potassium-deficient fruit trees may be 10%-20% lighter than normal fruits, and the vitamin C content in the fruit will also be reduced, affecting the taste and nutritional value of the fruit.

In addition, the stress resistance of plants will also be significantly reduced. Potassium-deficient plants have reduced resistance to adverse conditions such as drought, high temperature, and low temperature, and are more susceptible to pests and diseases. For example, under drought conditions, the relative water content of potassium-deficient wheat leaves is 10%-15% lower than that of normal plants, and the leaves are more likely to wilt and curl, and photosynthesis and transpiration are inhibited, thus affecting plant growth and yield. Moreover, due to poor growth, potassium-deficient plants are affected in their own defense mechanisms and are more susceptible to pathogens and pests, increasing the pressure of pest and disease control in agricultural production.

From the perspective of organic farming standards, not all granular potash fertilizers are suitable for organic farming. In the organic farming system, there are strict requirements on the source and production methods of fertilizers, emphasizing the use of natural inputs that are not over-processed by chemical synthesis and will not have a negative impact on the soil and the environment.

Some granular potash fertilizers from natural sources, such as products processed by physical methods from natural potash ore, may meet the use standards of organic farming. For example, after mining from a specific natural potash ore, the granular potash fertilizer is made only by simple physical means such as crushing and screening. Its chemical composition remains natural and does not contain harmful chemical synthetic additives. In this case, potassium can provide necessary nutrition for organic crops, promote crop growth, and enhance stress resistance. Studies have shown that the application of such granular potash fertilizers in soils that meet organic standards can increase the yield of organic vegetables by 10% - 15% on the original basis, and the plumpness and quality of the fruit are also significantly improved.

However, not all granular potash fertilizers can be used in organic farming. If the production process of granular potash fertilizer involves chemical synthesis, purification processes, or non-organic certified chemical additives are added to improve its performance, then such products do not meet the standards of organic agriculture. For example, some granular potash fertilizers synthesized through complex chemical processes may introduce heavy metal impurities or non-natural chemical residues in the production process. Long-term use may accumulate harmful substances in the soil, destroy the ecological balance of the soil, and threaten the sustainable soil environment and eco-friendliness pursued by organic agriculture.

Organic certification agencies have clear certification processes and standards for granular potash fertilizers used in organic agriculture. Producers need to provide detailed information such as the source and production process of potash fertilizers. After testing and review by the certification agency, and confirmation that the product meets the relevant organic standards, it is allowed to be used in organic agriculture. Only granular potash fertilizers that meet the standards can play a positive role in supplementing potassium nutrition and promoting crop growth in organic agriculture.

The first is to accurately control the application amount, which should be determined according to the soil fertility, crop type and its growth stage. Taking corn, a common field crop, as an example, in medium-fertility plots with soil available potassium content of 80-120mg/kg, the appropriate potassium chloride application amount per hectare is about 100-150 kg; if the soil available potassium content is higher than 120mg/kg, the application amount can be reduced to 75-100 kg/hectare. For crops with high potassium requirements, such as tobacco, under suitable soil conditions, the application amount of potassium sulfate per hectare can reach 200-300 kg. Excessive application will cause excessive soil salt concentration, hinder plant roots from absorbing water, cause seedling burning, and cause soil compaction and damage soil structure; insufficient application will fail to meet the crop's demand for potassium, affecting the normal growth and yield increase of crops.

Secondly, pay attention to the application method. Granular potassium fertilizer can be used as base fertilizer or topdressing fertilizer. However, when used as base fertilizer, it should be evenly spread on the soil surface before sowing or transplanting, and then plowed into the soil. The depth should be kept at 15-20 cm. This will allow the potassium fertilizer to be fully mixed with the soil and facilitate the absorption of crop roots. When used as topdressing fertilizer, direct contact with the crop root system and stem base should be avoided to prevent root burn. It can be applied by digging holes or trenches 10-15 cm away from the plant, and then covered with soil. The hole depth or trench depth is about 8-10 cm. For example, in an orchard, it is better to apply granular potassium fertilizer to fruit trees by digging a circular trench around the drip line of the tree crown. In addition, foliar spraying can also be used, but the concentration needs to be strictly controlled. Generally, the foliar spraying concentration of potassium chloride or potassium sulfate is 0.2%-0.5%. Too high a concentration can easily burn the leaves. During the key growth periods of crops, such as flowering and filling, spray once every 7-10 days, and spray continuously for 2-3 times, which can quickly replenish potassium and enhance crop resistance.

Furthermore, different types of granular potassium fertilizers are applicable to different situations. Potassium chloride is relatively cheap and has a high potassium content (generally about 60% in terms of K₂O), but it contains chloride ions. Chlorine-sensitive crops such as tobacco, potatoes, sweet potatoes, and tea trees should not be applied, otherwise the quality of the crops will be reduced. For example, after potassium chloride is applied to tobacco, the burning performance of tobacco leaves becomes worse and the aroma is reduced; while potassium sulfate is slightly more expensive, with a potassium content (in terms of K₂O) of 50%-54%, and contains about 18% sulfur, which is suitable for all kinds of soils and crops, especially chlorine-sensitive crops and sulfur-loving crops. In acidic soils, long-term and large-scale application of potassium chloride will increase the acidity of the soil, and it should be neutralized and improved with the application of alkaline substances such as lime. Generally, 1500-2000 kg of lime can be applied per hectare to adjust the soil pH value to the appropriate range (the suitable soil pH value for most crops is 6.0-7.5).

Conclusion:

In addition to the above uses, potash fertilizers are also very useful in many other fields. In the aluminum recycling process, it helps improve recycling efficiency and purity; in the production of explosives, whether it is colorful fireworks or daily matches, potash fertilizers are indispensable for participating in the reaction to achieve unique effects; in the pharmaceutical industry, as a key component of a variety of compounds, potash fertilizers play an important role in maintaining normal physiological functions of the human body and treating related diseases. Because it exists in the form of various compounds and its application scenarios are extremely flexible, the benefits that potash fertilizers bring to modern society are almost endless.

For more than 65+ years, Tongli has always focused on the research and application of various potash fertilizers, providing agglomeration and material handling equipment for potash fertilizer processing facilities around the world. In addition, Tongli's laboratory can test the feasibility of potash fertilizer granulation and agglomeration for different adhesives, equipment and process changes. If you want to learn more about granular potash fertilizers, please contact us now!