Introduction: What is Organic-Inorganic Fertilizer Production?

Organic-inorganic compound fertilizer refers to a compound fertilizer made by mixing organic fertilizer and inorganic fertilizer in a certain proportion. It is an organic combination of inorganic fertilizer and organic fertilizer. It is composed of the activity provided by organic fertilizer and the nutrients, catalytic power and regulators provided by inorganic fertilizer. It is the most promising emerging field in agricultural production today. The performance indicators of organic-inorganic compound fertilizer are mainly based on the content of organic matter and other active substances and inorganic salts (nitrogen, phosphorus, potassium, etc.). The proportion of its components is also affected by the nature and efficacy of the fertilizer. The content of organic matter and other active substances should meet national standards. The content of organic matter is between 10% and 20%, and the specific content should be adjusted according to factors such as soil conditions and crop types.

How Organic-Inorganic Fertilizer Enhances Crop Yields and Soil Health?

- Can improve soil and cultivate fertilizer: Generally, inorganic compound fertilizers are difficult to cultivate soil, and generally organic fertilizers have a great effect on cultivating soil, but the fertilizer supply in the season is insufficient. Organic compound fertilizers have the function of using soil and cultivating soil. Because organic compound fertilizers usually contain 20% to 50% of organic fertilizers in the total mass, and contain a considerable amount of organic matter, they can improve the physical and chemical properties and biological properties of the soil.

- Activate soil nutrients: Through the chemical and biochemical effects of organic compound fertilizers, nitrogen, phosphorus, potassium, silicon, manganese, zinc, boron and other nutrients in the soil can be activated. On the one hand, organic compound fertilizers can enhance the activity of microorganisms in the soil, including phosphorus bacteria, potassium bacteria and silicon bacteria, which not only promotes the decomposition of organic matter, releases nitrogen, phosphorus and trace elements, but also makes mineral phosphorus, potassium, silicon and other nutrients effective; on the other hand, organic compound fertilizers can also adjust the soil pH value to a certain extent, so that the micro-domain soil pH value is in a range that is conducive to the activation of most nutrients. For example, the organic acid produced by the decomposition of organic matter has a significant activation effect on phosphorus.

- Physiological regulation: Since the organic components in organic compound fertilizers contain a considerable amount of physiologically active substances, such as amino acids, humic acid and enzymes, in addition to general nutritional effects, they also have unique physiological regulation effects, such as promoting root respiration, nutrient absorption and leaf photosynthesis. Due to the scientific combination of organic and inorganic components, organic compound fertilizers combine the advantages of chemical fertilizers and organic fertilizers and surpass them, just as farmers say, "It is not a chemical fertilizer, but better than chemical fertilizers; it is not peanut bran, but better than peanut bran." Organic compound fertilizers are effective carriers of a variety of scientific and technological achievements, with high technical content, and therefore have obvious advantages.

Organic vs. Inorganic Fertilizers: Why Combining Them Works Best ?

Organic compound fertilizers contain both chemical fertilizer components and organic matter. The proper combination of the two makes them more comprehensive and superior than inorganic compound fertilizers and organic fertilizers. Organic compound fertilizers can not only achieve the nutrient balance of nitrogen, phosphorus, potassium and other nutrients of general inorganic compound fertilizers, but also achieve a unique organic-inorganic balance. The quick-acting nutrients from inorganic fertilizers in organic compound fertilizers are supplied quickly but not too fiercely under the regulation of organic fertilizers, while the slow-acting nutrients from organic fertilizers can ensure the long-term supply of nutrients in organic-inorganic compound fertilizers, making them have the characteristics of combining urgency with urgency, combining long-term and short-term, and balanced and stable fertilizer supply. It not only avoids the shortcomings of the ups and downs of chemical fertilizer nutrient supply, but also avoids the disadvantages of insufficient nutrient supply in the early stage caused by the single application of organic fertilizers, or the time-consuming and labor-intensive application of large amounts of organic fertilizers. Moreover, organic compound fertilizers have strong fertilizer retention performance and less fertilizer loss. In addition, due to the presence of organic matter, phosphorus in compound fertilizers is not as easy to be fixed by the soil as inorganic phosphorus fertilizers, so the fertilizer utilization rate is high. Compared with inorganic compound fertilizers, it can achieve higher crop yields under conditions of lower nitrogen, phosphorus and potassium content.

Top 5 Technologies Used in Organic-Inorganic Fertilizer Manufacturing

- Pretreatment of raw materials: Since calcium carbonate contains 4% to 5% free acid, if it is not pretreated, it will affect the subsequent granulation process. Ammoniation treatment is often used to eliminate excessive residual acid, which is also conducive to loosening the material and facilitating crushing. A certain proportion of ammonium carbonate (or fly ash, carbon filter mud) can be pre-mixed with calcium carbonate for several days. However, the proportion of ammonium carbonate should not be too high, otherwise it will affect the effectiveness of phosphorus. Production practice shows that the ratio of calcium carbonate to ammonium carbonate is 10:1 (mass ratio). For organic waste raw materials, they can be treated by composting or directly dried to reduce the moisture content of the material, which is conducive to the subsequent crushing process.

- Crushing of raw material: Coarse particles and agglomerated materials must be crushed first, otherwise the various fertilizers will not be evenly matched and it will be difficult to granulate. Different crushing machines are used depending on the material. For plant fiber materials, hammer and knife crushers are suitable; for ore and filter mud blocks, chain crushers are suitable. Urea potassium fertilizer and other chemical fertilizers do not need to be crushed after mixing, and the granulation effect is also very good.

- Measuring and mixing: According to the requirements of the formula, weigh a certain amount of various raw materials, mainly organic fertilizers and three inorganic fertilizers of nitrogen, phosphorus and potassium, and convey them to the mixer. The mixer can be a drum type or a vertical disc. The mixing must be sufficient and ready to use. It is not advisable to leave it for too long after mixing to avoid moisture.

- Granulation: Granulation machinery is the most common type of extrusion and disc type. Inorganic compound fertilizers usually use disc granulation, which has low energy consumption, rounder granules, and more suitable appearance for market demand. However, for organic compound fertilizers, extrusion granulation is more appropriate. This is because organic materials contain fibrous materials, such as bagasse, hemp residue, etc. After crushing, a considerable part of this type of material is still in long strips, and the extruder should have a strong extrusion force to combine it with other powders into compact granules. If granulation is performed on a disc, it is required to strictly crush this type of fibrous material, which is actually difficult to do. Therefore, it is generally recommended to use an extruder for granulation. However, for materials such as peanut bran, bean bran, filter mud, and sludge, disc granulation can be used after crushing to produce fertilizers with higher prices for flowers. The moisture content of all raw materials of organic compound fertilizer should be controlled between 15% and 18% after mixing, which is conducive to granulation and reduces the load of drying. The appropriate moisture content can be roughly judged by experience: when the material is held and then released, the material group will crack, and the moisture content of the material is moderate in this state.

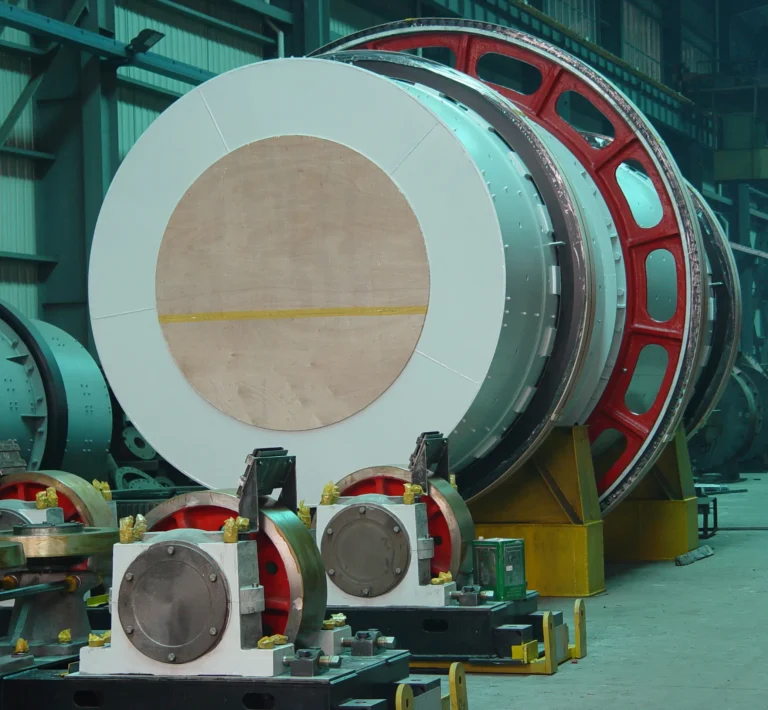

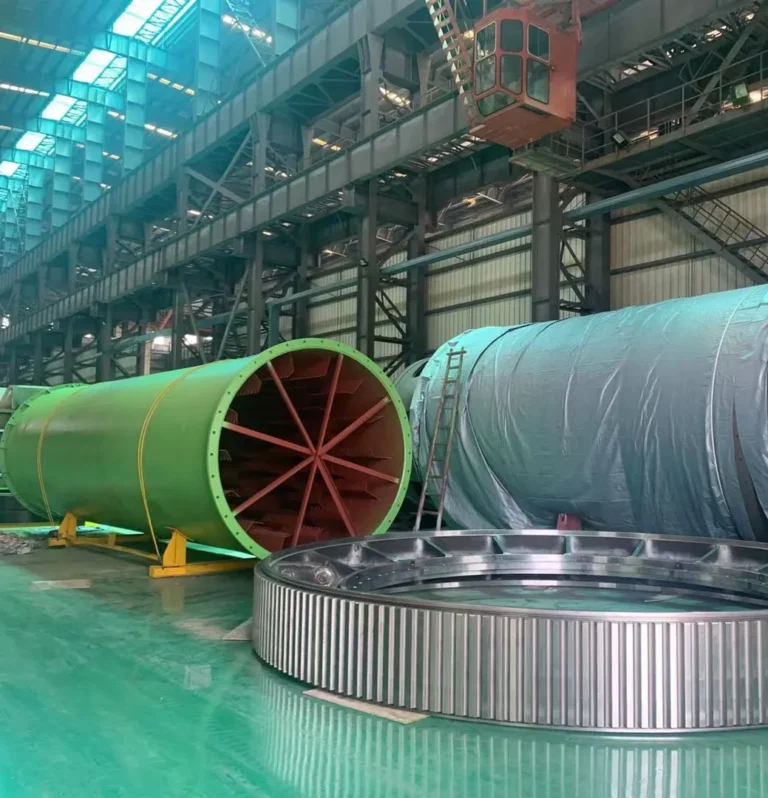

- Drying: After granulation, the product needs to be dried using rotary drum dryer. Generally, it is not suitable to use the high temperature (200-300℃) conditions used for inorganic compound fertilizers. Organic compound fertilizers contain heat-sensitive materials such as urea, which are easy to lose under high temperature conditions, so low temperature is emphasized for drying, and the general hot air temperature is around 90℃. It can be considered to use waste heat for drying. If the moisture content of organic compound fertilizer is below 12%, it will generally not be scattered and moldy. The moisture content of extruded granular fertilizer is about 15%, and the moisture to be removed is not large. There are also many manufacturers who adjust the moisture content of the material and do not dry it after granulation, but the granulation speed is slow. Generally speaking, if hot air drying is not used, cold air drying should be used as much as possible.

- Cooling process: Cooling is one of the key links in the production line, mainly used to reduce the temperature of granular fertilizer. A rotary cooler is usually used, which introduces cold air through a blower and uses convection and conduction between the material and the air for heat exchange. The temperature of the fertilizer after cooling is close to room temperature. This process helps to improve the strength of the particles and reduce the moisture content, providing stable material conditions for subsequent processes.

- Coating process: The coating process is completed by a coating machine, which is used to spray a protective film on the surface of the fertilizer particles. The coating material usually includes an anti-caking agent or special grease, the purpose of which is to prevent the particles from agglomerating during storage and transportation, while improving the fluidity and long-term effectiveness of the fertilizer. The coating process can significantly improve the product quality of the fertilizer and meet the market demand for high-performance fertilizers.

- Screening process: Screening is an important step to ensure that the finished fertilizer particles are uniform in size. Vibrating screens and drum screens are the main equipment, which separate oversized particles and powders. Qualified particles enter the subsequent process, while unqualified materials are returned to the production line for reprocessing. Screening accuracy directly affects the appearance quality and user satisfaction of the final product.

- Automatic metering and packaging process: Automatic metering and packaging machines are responsible for accurately packaging finished fertilizers according to the set weight. These devices are usually equipped with electronic scales or sensors to ensure accurate metering and can achieve fast packaging. Packaging methods include sewing, heat sealing and folding, providing flexible packaging solutions for different types of fertilizers.

- Palletizing process: Palletizing is the last step of the production line. The packaged fertilizers are neatly stacked on pallets by automatic palletizing robots. Modern palletizing systems use programming control to efficiently complete stacking according to preset patterns, saving labor costs and improving work safety. Pallets after palletizing are easy to load and unload and transport, improving logistics efficiency.

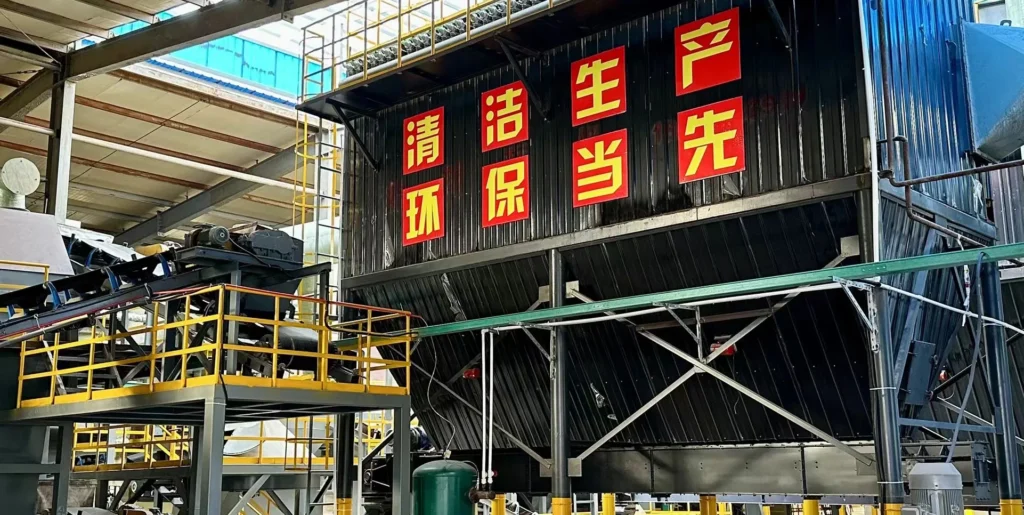

Environmental Impacts of Organic-Inorganic Fertilizer Production and Mitigation Strategies

- The content of nitrogen, phosphorus and potassium The total nutrient content (N+P2O5+K2O) of ternary inorganic compound fertilizer is required to be ≥25%, while the national standard for organic compound fertilizer under review is ≥15%. Although the latter has lower nitrogen, phosphorus and potassium, it has higher organic matter (more than 20%), and the total content of the four elements (N+P2O5+K2O +OM) is more than 35%. According to research, on the basis of equal quality, this organic compound fertilizer has the same or better fertilizer effect as the inorganic compound fertilizer with a total nutrient content of 25%.

- In addition, the requirement for single nutrients in organic compound fertilizer (≥2%) is also lower than that of inorganic compound fertilizer (≥4%), especially in the usual organic compound fertilizer formula, the P2O5 content is lower than that of inorganic fertilizer, considering that the effectiveness of phosphorus will be improved by the effect of organic matter.

- Organic matter content Organic matter content is a unique indicator of organic compound fertilizer. It is worth mentioning that the current method for determining organic matter is still based on the oxidation of organic carbon by potassium dichromate-concentrated sulfuric acid, which may make it difficult to distinguish organic compound fertilizers with the same organic matter content but with greatly different activity and fertilizer effect. The method of measuring the quality of organic components in organic compound fertilizers by what indicators is still to be improved. Nevertheless, the organic matter content obtained by potassium dichromate-concentrated sulfuric acid oxidation method is not less than the specified standard, which is still a method to identify genuine organic compound fertilizers.

- Moisture The minimum requirement for moisture in organic compound fertilizers is 2 times higher than the 5% in the standard of inorganic compound fertilizers. This is related to the characteristics of organic raw materials in organic compound fertilizers. Because organic raw materials have strong water absorption, especially fiber raw materials. Under the condition of 10% moisture, the hardness of organic compound fertilizers is enough to ensure that the breakage rate during transportation is lower than a certain percentage, and it will not mold or cause fertilizer loss during storage. Further reducing the moisture of organic compound fertilizers will lead to excessive energy consumption and may cause nitrogen loss.

- Other organic compound fertilizers have limits on pH value, pathogens, etc., which are not available in inorganic compound fertilizers. This is related to the properties of organic matter. Application of organic compound fertilizers Like inorganic compound fertilizers, organic compound fertilizers must consider factors such as soil, crops and climate when applying them. It is worth pointing out that although organic compound fertilizer contains a considerable amount of organic matter, has certain effects on soil improvement and fertilization and nutrient control release, its effect is ultimately limited. Unlike the large-scale application of organic fertilizer as base fertilizer, the actual amount of organic matter input per unit area of farmland when applying organic compound fertilizer is quite small. Therefore, for some soils, attention should be paid to the input of organic fertilizer and the problem of supplementary fertilizer in the later stage. For example, for sandy soil, since the mineralization of organic matter is relatively fast and the soil has poor fertilizer retention, proper attention should also be paid to the problem of soil defertilization in the middle and late stages. Organic compound fertilizer can generally be used as base fertilizer, topdressing and seed fertilizer. However, when used as seed fertilizer, especially when applying in strips, spots and holes, it is necessary to avoid direct contact with seeds to avoid the degradation of organic matter and the adverse effects of chemical fertilizers on seed germination.

The Role of Automation in Modern Organic-Inorganic Fertilizer Plants

- Automatic batching system: Tongli's organic and inorganic compound fertilizer production line can accurately measure the weight and proportion of various raw materials through advanced Omron, HBM, Suncells, Toledo sensors and control equipment to ensure that the produced fertilizer meets the specified nutrient ratio. By adjusting the formula on the industrial control screen instead of manual adjustment, it not only improves the accuracy of the ingredients, but also reduces the errors and waste caused by human operation. At the same time, in order to cope with emergencies, it is also equipped with instruments that can manually adjust the formula to avoid the inability to adjust the production line parameters in the event of power outages or computer failures.

- Automatic control: Tongli state of art NPK organic compound fertilizer production lines widely use automatic control technologies such as PLC (programmable logic controller) to monitor and adjust each link in the production process in real time. Automatic control can ensure that the equipment operates under the best parameters and improve production stability. The operating data of the fan and each motor can be seen on the central console, and an emergency stop button is equipped.

- Automatic temperature detection: In processes such as drying and cooling, temperature control is crucial to product quality. Automatic temperature detection equipment can collect temperature data of materials in real time at the inlet and the outlet of the dryer and hot air generator, and combined with the automatic adjustment system, accurately control the drying temperature or cooling speed, thereby avoiding fertilizer quality problems caused by abnormal temperature.

- Automatic packaging: Tongli automatic packaging equipment uses Japanese imported instruments and pneumatic components, which can complete the weighing, bagging and sealing of fertilizers at high speed, with an output of 800-1000 bags per hour. Through the electronic weighing and packaging system, it can ensure that the weight of each bag of fertilizer is accurate and the seal is tight, which improves packaging efficiency and reduces labor costs.

- Automatic bagging and palletizing: After the packaging is completed, the automatic bagging and palletizing robot takes over the subsequent work. Tongli is equipped with ABB and Fanuc robot arms, which can quickly and accurately stack the packaged fertilizers on the pallet, improving efficiency while reducing the labor intensity and safety risks of manual handling.

Maximizing Efficiency in Fertilizer Production with Combined Organic-Inorganic Methods

- Urea and calcium sulfate are easy to produce water after mixing. If all materials are not granulated immediately after mixing, they are easy to become wet and agglomerated, and may become hard in the storage tank and difficult to remove. When the machine is not debugged, it is not advisable to mix the ingredients first, or the ingredients should be left to the end before adding urea.

- The materials should be mixed evenly, otherwise the nutrient content and pH value of the product will fluctuate, which is not good for crop growth. In the production, if the phosphate fertilizer is not completely crushed, the small granular phosphate fertilizer entering the material making machine may produce granular fertilizer mainly composed of phosphate fertilizer, which is easy to cause acid damage after application. Under the condition of normal feeding amount and raw material quality. Unstable product quality is often related to uneven mixing.

- Do not change the type and quantity of waste materials at will. Some people can strictly implement the feeding amount of each component of the fertilizer in the formula, but think that the waste raw materials are general "fillers" and do not take it seriously. Random changes in their types and quantities have also caused quality problems. Some raw materials can be substituted for each other, such as bagasse and peat, but not furfural residue. Fly ash and carbon filter mud are both slightly alkaline, but whether they can replace each other and to what extent depends on the original purpose of the formula and the object of application. The addition of waste raw materials is not only for its chemical composition, but also for its conditioning effect.

Solutions in Organic-Inorganic Fertilizer Manufacturing: Optimizing Raw Material Ratios

The fundamental difference between organic compound fertilizer and inorganic compound fertilizer is that the former has a certain amount of organic components. When mixing organic materials with chemical fertilizers, the premise is that the advantages of organic-inorganic compound fertilizers can be fully utilized. In actual production, the combination of organic and inorganic fertilizers is mainly considered from the two aspects of organic N-inorganic N ratio and C/N.

- Organic N-inorganic N It is reported that the appropriate ratio of organic N-inorganic N in farmland fertilization in my country is roughly 1:1, 7:3 or 6:4, but the specific ratio to be used should be determined by the differences in crops, soil, fertilization and region. For fertile soil, the inorganic N ratio can be higher, and for lean soil, the organic N ratio should be higher. It is worth pointing out that when using organic materials with a C/N width (higher than 40) as organic compound fertilizer raw materials, it is not appropriate to apply them mechanically. Organic N-inorganic N ratio. Because if the same organic N-inorganic N ratio is achieved, this wide C/N organic material may account for a considerable proportion of the total compound fertilizer quality, which is difficult to implement in actual production, and may affect the N supply of compound fertilizer due to C/N issues.

- C/N From the perspective of fertilizer, C/N is an important factor in regulating the intensity and durability of N supply, and is one of the bases for the manufacture of organic compound fertilizers and the combination of organic and inorganic. However, different organic materials not only have large differences in C/N, but also have very different biological effectiveness of organic C. In the production of organic compound fertilizers, it is necessary to determine the type and proportion of raw materials based on the composition of organic C. Generally speaking, if cellulose is used as the main organic raw material, the C/N of organic compound fertilizers should be 1.0-1.6. If the effective C ratio is higher, the C/N should be lower; otherwise, it should be higher. For formulations aimed at improving soil and supplementing organic matter, the C/N can be above 1.6. The determination of the organic-inorganic ratio needs to consider soil and crop factors. For lean sandy soil and crops with long growth periods, attention should be paid to the persistent and stable fertilizer supply, and the C/N ratio should be higher; otherwise, it should be lower. At present, the proportion of organic materials in the production of organic compound fertilizers in my country is roughly between 20% and 50%, but most of them are around 30%. As for what kind of organic materials to choose based on the above principles, it is also necessary to consider the price and abundance of raw materials in various places and make appropriate adjustments.

- The ratio of nitrogen, phosphorus and potassium: The nutrient design of compound fertilizers mainly considers three factors: crops, soil and fertilizers, which is basically similar to the nutrient design of inorganic compound fertilizers. Therefore, the formula of organic compound fertilizers can refer to the existing nutrient ratio of inorganic compound fertilizers, but it cannot be copied, because the nitrogen, phosphorus and potassium ratio in organic compound fertilizers has its own particularity. It is mainly manifested in that the nitrogen supply process of organic compound fertilizers fluctuates less, is more stable, and will not fluctuate greatly. The fertilizer supply intensity and persistence are more coordinated, and are more adapted to the fertilizer requirements of crops at different growth stages. The phosphorus fertilizer in organic compound fertilizer is more effective and not easy to be fixed. Therefore, the proportion of nitrogen fertilizer in organic compound fertilizer can be appropriately higher without excessive strength, and the proportion of phosphorus fertilizer can be appropriately lower without insufficient phosphorus supply. For example, for a certain soil, the three elements of inorganic compound fertilizer are 12-7-10, which is a good special fertilizer for leafy vegetables. The corresponding organic compound fertilizer can be 12-5-10, which also achieves ideal results.

Nutrient design for general and special fertilizer formulations

| Ratio | Urea | NH4NO3 | Ammonium Phosphate & | SSP | K2SO4 | KCL | Concentrate Liquid | Filter Mud | Bagasse | Marble Powder | Fly Ash |

| 11-3-7 | 23.50% | 21% | 11% | 20% | 6% | 10.50% | 10.50% | ||||

| Tobacco (9.0-5.4-16) | 9.60% | 10% | 8% | 15% | 25% | 5.80% | 10% | 7.40% | 5% | 5% | |

| Tea (14-2.9-3.0) | 30.40% | 21% | 5% | 20% | 10% | 9.60% | |||||

| Sugarcane (11-3-9) | 24% | 21% | 15% | 15% | 15% | 10% | |||||

| Banana (9-2.4-15) | 18% | 4% | 4% | 25% | 10% | 10% | 19% | 5% | 5% | ||

| Peanut (9-3.5-8) | 19.50% | 25% | 13% | 10% | 10% | 10% | 8% | 5.50% | |||

| Leafy Vegetables | 16.50% | 10% | 21% | 11% | 20% | 10% | 7% | 7% | |||

| Tomato | 21.70% | 21% | 15% | 20% | 8% | 10% | 2.30% |

Exploring the Market Trends for Organic-Inorganic Fertilizer Blends

Global organic agriculture trends

Globally, organic agriculture is becoming an important direction for agricultural development, and governments of various countries are constantly increasing policy support and financial investment in organic agriculture. According to statistics, the average annual growth rate of organic agriculture area and output exceeds 10%. For example, the proportion of organic fertilizers used in agriculture in the United States reached 46%, the United Kingdom was 57%, Germany was 60%, France was 37%, Australia was 55%, Canada was 60%, and Japan was as high as 76%. These countries are not only active practitioners of organic agriculture, but also important markets for organic-inorganic compound fertilizers.

What are the advantages of organic-inorganic compound fertilizers?

Traditional organic fertilizers and inorganic fertilizers have their own limitations in nutrient release and utilization efficiency: organic fertilizers release nutrients slowly and have low content; inorganic fertilizers have high content, but excessive use may cause soil pollution. To address this problem, organic-inorganic compound fertilizers combine the advantages of both by optimizing nutrient ratios:

- Balanced nutrient supply: adjust nutrient ratios according to the needs of different crops and soils to better meet the growth needs of crops.

- Improve utilization efficiency: It has the long-term effect of organic fertilizer and the rapid supply characteristics of inorganic fertilizer, which significantly improves the nutrient absorption rate of crops.

- Improve soil health: Reduce chemical pollution, increase soil organic matter content, and promote agricultural ecological balance.

Market Analysis and Prospects: Policy and resource support

The current agricultural use of organic fertilizers in China is only 20%, which is far lower than many developed countries. If the use of organic fertilizers is increased to 50%, it is equivalent to an annual output of 600 million tons of organic fertilizers, and its total market output value is expected to reach 500 billion yuan. This provides a broad space for the development of organic and inorganic compound fertilizers.

In recent years, driven by the "zero growth" policy of chemical fertilizers, the implementation of the "Ten Articles on Soil" and tax incentives, the average annual growth rate of China's organic fertilizer industry has reached 12.5%. However, the industry is still dominated by small and medium-sized enterprises. Among the 2,283 enterprises, the total production volume is less than 10 million tons, and the distribution is relatively scattered. Transformation and upgrading and integration of resources have become the key to future development.

China has abundant organic fertilizer raw materials, including manure fertilizer, straw fertilizer, marine fertilizer and urban waste. These diverse resources provide unique conditions for the production of organic-inorganic compound fertilizers. At the same time, a series of encouraging policies introduced by the government, such as value-added tax reduction and exemption and special subsidies, have injected strong impetus into the industry.

5 Top challenges in the organic and inorganic fertilizer production industry

- Technical bottleneck: Some companies have technical bottlenecks in microbial screening, cultivation, and application, which affects product quality and market competitiveness.

- Cost issues: The production cost of organic fertilizers is relatively high, resulting in high product prices, which affects its popularity and promotion in the market.

- Insufficient market awareness: Some farmers are not aware of organic fertilizers and still tend to use traditional fertilizers, which limits the market demand for organic fertilizers.

- Unstable supply of raw materials: The raw materials of organic fertilizers mainly come from livestock and poultry manure, agricultural waste, etc. The supply and quality of these raw materials are affected by many factors, such as policy adjustments and price fluctuations.

- Fierce market competition: As more and more companies enter the organic fertilizer industry, market competition is becoming increasingly fierce. Companies need to continuously innovate and improve product quality to cope with market competition.

Conclusion:

Organic fertilizer, also known as ecological fertilizer, is a kind of fertilizer made from high-quality animal and plant organic matter and processed by specific processes (such as microbial fermentation, deodorization and complete decomposition). It is not only rich in a variety of functional microorganisms and trace elements, but also can effectively improve soil nutrients, increase soil organic matter and fertility, reduce pesticide application, and optimize soil ecological environment. As an important driving force for the development of organic agriculture, organic-inorganic compound fertilizers have broad application prospects in the market. It can regulate the proportion of nutrients and is suitable for the planting needs of different crops. With the rapid development of global organic agriculture and the advancement of agricultural technology, the market for organic-inorganic compound fertilizers will surely usher in a broader development space.