-

1. Why choose Tongli Heavy Machinery as the EPC contractor for compound fertilizer production line?

Tongli Heavy Machinery has rich experience in EPC projects and has successfully completed 100+ compound fertilizer projects, covering drum granulation, high tower granulation, extrusion granulation and BB fertilizer production line.

Secondly, Tongli has been producing compound fertilizer equipment since 1958 and has accumulated rich experience and patents. In addition, Tongli has long-term cooperation with internationally renowned companies such as Yara, BASF, Thyssenkrupp, etc., and product reliability is guaranteed.

Our engineering team is good at providing customized solutions according to customer needs, and issuing appropriate process flow and equipment plant layout according to the type of raw materials and site conditions of customers.

-

2. What are the technical advantages of Tongli Heavy Machinery’s compound fertilizer equipment?

From a process perspective, Tongli’s process flow is more advanced than that of other companies. Due to its large population base, China has an extremely strong demand for compound fertilizers. In the past 20 years, a large number of compound fertilizer plants have been built across the country.

Tongli has not only witnessed the continuous iteration of compound fertilizer production technology, but also accumulated rich experience in the process. At present, Tongli’s compound fertilizer production process has reached the leading level at home and abroad.

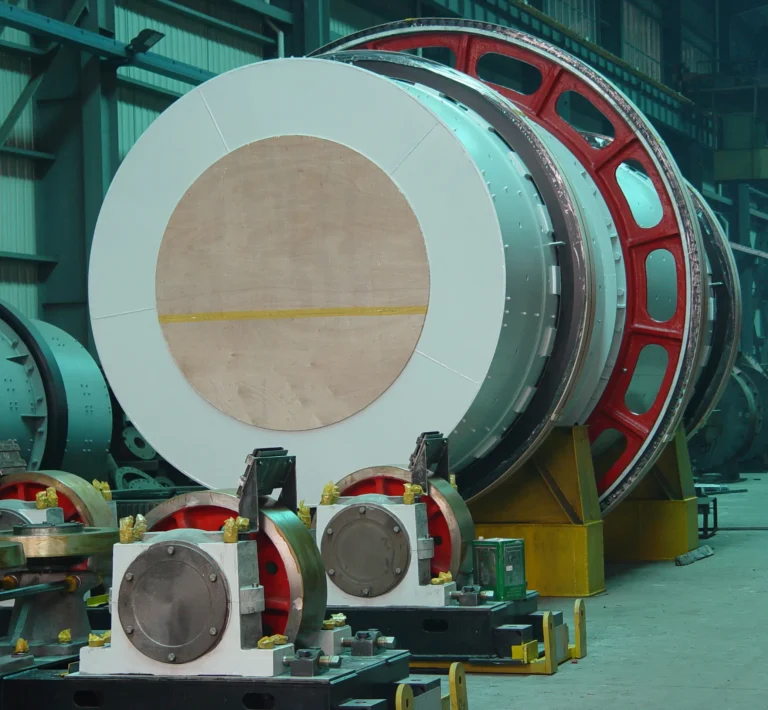

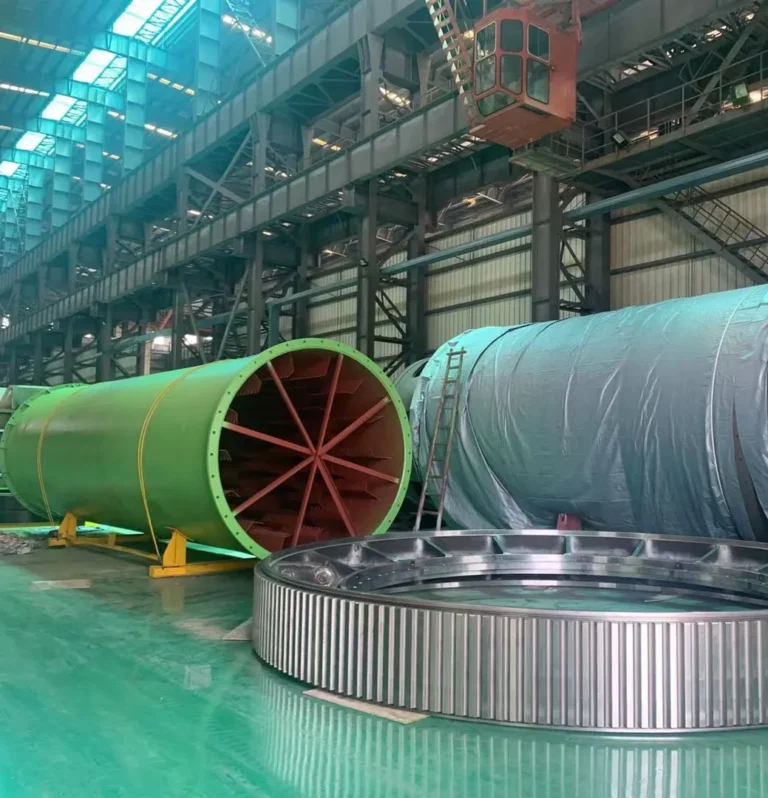

Tongli’s production line equipment has reliable quality, selection of high-quality raw materials, state-of-the-art product structure design and advanced processing equipment. In addition, Tongli has very rich project experience and has successfully built more than 15 compound fertilizer drum granulation production lines in the UAE, Africa, Indonesia and other places in recent years.

-

3. What types of compound fertilizer production lines does Tongli Heavy Machinery provide?

Tongli Heavy Machinery provides a variety of compound fertilizer production lines to meet the needs of different customers, covering production processes from basic to high-end. The main products include NPK steam drum granulation production line, high tower compound fertilizer production line, extrusion granulation production line and BB fertilizer production line.

NPK steam drum granulation production line has high capacity and stability, suitable for large-scale production.

High tower compound fertilizer production line manufactures high-quality fertilizers through the molten urea process, suitable for products with complex formulas.

Extrusion granulation production line is designed for the production of granular fertilizers, with advantages such as low energy consumption and low investment.

BB fertilizer production line focuses on simple and fast mixing and packaging, suitable for small batch production. All types of production lines can be customized according to customer needs to help enterprises improve production efficiency.

-

4. What is the annual output range of Tongli NPK compound fertilizer production line?

The annual output range of Tongli compound fertilizer production line is wide, usually ranging from 30,000 tons per year to 300,000 tons per year. Smaller production lines, such as systems with an annual output of 30,000 tons of blended fertilizer, are suitable for small and medium-sized enterprises, with relatively less equipment investment and lower energy consumption.

For large-scale drum production lines with an annual output of 300,000 tons, the advantage is that they can be produced on a large scale. Although the initial investment and energy consumption of large-scale production lines are relatively high, the production cost per ton of products is reduced due to economies of scale and improved automation, thus bringing more significant economic benefits. Overall, the choice of the appropriate annual output depends on the scale of the enterprise and market demand.

-

5. Which international compound fertilizer brands choose to cooperate with Tongli?

As a leading compound fertilizer equipment manufacturer in China, Tongli has established cooperative relations with many well-known international and domestic compound fertilizer brands. In the international market, Tongli’s partners include international fertilizer giants such as BASF and Yara International. Tongli has also cooperated with many large domestic fertilizer companies, such as Stanley, Jinzhengda, Xinyangfeng, Xinlianxin, Xiangyun and other large fertilizer groups.

-

6. How does Tongli Heavy Machinery’s equipment ensure the quality and consistency of compound fertilizer production?

1. First of all, Tongli’s drum granulator adopts a high-precision temperature control system and a uniform material distribution design, so that the particle size and quality of each batch of products are uniform. Advanced temperature and humidity sensors are introduced in the design process, which can monitor and adjust the key parameters in the production process in real time to ensure good agglomeration and uniformity of the particles.

2. Large particles and powdered materials need to go through 3 different screenings, and unqualified particles will be re-granulated to ensure particle size and strength.

3. The production line is also equipped with efficient automation systems and online detection devices, such as automatic batching systems and particle detectors, which can monitor and adjust the formula in real time during the production process to ensure that each batch of products meets the set quality standards. Its automated packaging system can maintain extremely high packaging accuracy and consistency at a speed of 5,000 bags per hour.