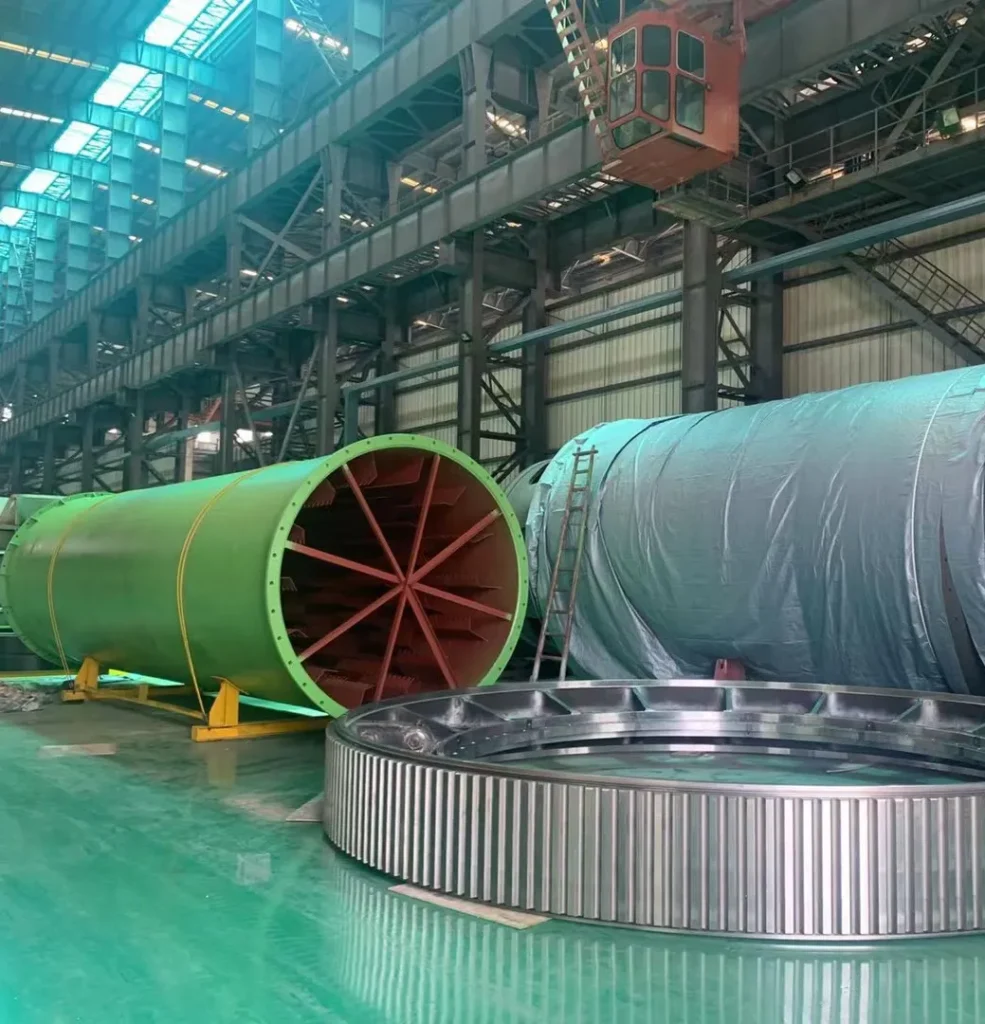

Tongli Compound Fertilizer Cooler is a device specially designed to reduce the temperature of compound fertilizer, usually after the granulation or drying process. Its core is a rotating cylinder structure, which quickly reduces the material temperature from 80-100°C to normal temperature (about 30-40°C) through convection and conduction. This helps prevent fertilizer clumping and improves storage and transportation performance. The equipment adopts a high-efficiency transmission system and is usually equipped with a 5-15kW motor. Depending on the production scale, the processing capacity can reach 5-30 tons/hour. The cooling medium is mostly air, and a properly designed heat exchange mechanism can significantly reduce energy consumption. Its structure is simple and easy to maintain, and it is suitable for various fertilizer production lines. The cooler improves the quality stability of the product and is an indispensable equipment in modern fertilizer production.

Efficient Compound fertilizer cooler Solution

A MACHINE YOU CAN DEPEND ON!

Tongli compound fertilizer rotary cooler adopts countercurrent cooling process, which improves cooling efficiency by 25%. The cylinder length reaches 15-55 meters to achieve uniform cooling. The spiral transmission structure is optimized, the material flow rate is controllable, and the breakage rate is reduced to less than 5%. The fully sealed design reduces dust emission by 30% to ensure environmental protection standards. The automatic control system reduces labor costs by 20%.

The Tongli compound fertilizer cooler adopts a countercurrent design. In this design, the flow directions of raw materials and air are opposite. The raw materials enter from the upper end, while the air is discharged from the lower end. This countercurrent flow improves heat transfer efficiency and reduces energy consumption

The residence time of the material in the cooler directly affects its cooling efficiency. The internal design of the Tongli cooler ensures that the material passes through the cooler at an appropriate speed to achieve the required cooling without excessive or insufficient residence time. The elevator or scraper inside the cooler controls the movement and residence time of the material.

The main purpose of the Tongli rotary cooler is to effectively exchange heat between hot fertilizer and cooling medium. To achieve this, the cooler should be designed to maximize the contact area between the material and the cooling medium. This is often accomplished by designing the cooler with internal lifts, baffles, or other features that enhance material movement and mixing.

| Specification | Inner Diameter (mm) | Length (mm) | Incline (°) | Speed (r/min) | Capacity (t/h) | Flow Direction | Main Motor | Power (kW) | Main Reducer | Speed Ratio | Dimensions (L×W×H) (mm) | Weight (t) |

| Φ1.8×14 | 1800 | 14000 | 2.5 | 3.08 | ~12 | — | Y225S-8 | 18.5 | ZL65 | 25 | 14680×3460×3711 | 24.5 |

| Φ2.0×16 | 2000 | 16000 | 2.5 | 3 | ~16 | Co-current | Y225M-8 | 22 | JZQ750 | 31.5 | 17580×3965×4400 | 40 |

| Φ2.2×15 | 2200 | 15000 | 2.5 | 3.33 | ~18 | Counter-flow | Y225M-8 | 22 | ZL65 | 31.5 | 17090×4460×5250 | 43 |

| Φ2.4×18 | 2400 | 18000 | 2.5 | 2.58 | ~25 | — | Y280M-8 | 45 | ZL100 | 40 | 18830×4097×5932 | 63 |

| Φ2.6×22 | 2600 | 22000 | 2.5 | 2.58 | ~30 | — | Y315S-8 | 5 | ZL100 | 35.5 | 23000×4400×7100 | 75 |

| Φ2.8×24 | 2800 | 24000 | 2.5 | 3.5 | ~35 | — | Y315M-6 | 90 | ZL115 | 35.5 | 25000×4220×5100 | 88 |

| Φ3.0×24 | 3000 | 24000 | 1.8 | 4.3 | ~45 | — | Y315L1-4 | 160 | ZL130 | 40 | 26615×5760×6269 | 122 |

| Φ4.2×15 | 4200 | 15000 | 1 | 3.5 | ~55 | — | YKK3554-4 | 250 | ZSY500 | 50 | 17208×6183×7985 | 178 |

QUALITY NEVER GOES OUT OF STYLE

The working principle of a compound fertilizer cooler involves passing ambient or cool air through a horizontally rotating drum. Materials are fed into the opposite end of the drum, creating a counterflow with the air. The cooler is slightly inclined downward to allow gravity to assist the material in moving through the equipment.

As the drum rotates, material lifters pick up the material and drop it through the airstream, forming a "curtain" across the drum's cross-section. This maximizes heat transfer between the material and the air. This cascading motion sometimes leads to these coolers being referred to as cascade coolers.

As continuous industrial coolers, materials are continuously fed and discharged. This ensures efficiency in the cooling process and maintains a steady production flow.

The design process is similar to that of rotary dryers, where engineers must balance various variables to correctly size and design the cooler. This includes material characteristics such as bulk density and inlet and outlet temperatures.

Production standards, such as required throughput, retention time, and cooling medium, also need to be considered. In some cases, flight design and patterns, which are highly customizable, may need to be tested in a flight simulator to determine the most suitable arrangement based on the material's unique properties.

The overall design aims to optimize the cooling process to ensure efficiency and effectiveness in meeting production goals.

Besides feed and discharge conveyors, a cooler requires exhaust systems and particle handling systems, typically involving a baghouse or scrubber combined with an ID fan. If excessive residue is expected, adding a cyclone separator may be beneficial to the process.

For particularly hot incoming materials, water can be added directly at the inlet, and refractory lining may be required at the drum's entrance to protect the shell until the material cools slightly.

Waste heat recovery systems can also be advantageous, capturing hot air generated during cooling for reuse in previous drying or kiln processes, reducing fuel and energy costs associated with drying or thermal processing stages.

Compound fertilizer coolers are suitable for various types of compound fertilizers, such as NPK fertilizers, urea, and ammonium nitrate. The equipment can adjust lifter angles and rotation speeds to handle materials with different forms and characteristics.

Whether granular or powdery fertilizers, the cooler effectively reduces temperature, ensuring uniform cooling. Selecting the appropriate cooler requires considering the type of fertilizer and production line needs to ensure equipment performance aligns with production targets.

By optimizing the cooling process, the physical stability of the fertilizer is enhanced, reducing caking and improving usability and storage performance.

Different types of compound fertilizers have varying requirements for coolers. For instance, high-nitrogen fertilizers are hygroscopic and require cooling under low humidity conditions. Phosphorus and potassium fertilizers need to control the temperature gradient during cooling due to higher hardness requirements.

Data shows that optimizing the cooling process for specific needs can improve product quality by about 20%. Specific measures include adjusting airflow, cooling medium velocity, and temperature.

Customized cooling solutions ensure consistency in chemical composition and physical properties, meeting diverse market needs and enhancing product competitiveness.

A compound fertilizer cooler enhances productivity by efficiently reducing the temperature of the fertilizer, allowing for faster packaging and storage. This process minimizes downtime between production stages, ensuring a continuous workflow.

By maintaining optimal temperature and preventing moisture buildup, the cooler reduces the risk of caking, which can disrupt production. This ensures that the quality of the fertilizer remains consistent, reducing waste and rework.

Additionally, by integrating a cooling process, the production line can handle higher throughput, making the overall process more efficient and cost-effective.

The cooler helps to quickly reduce the temperature of the fertilizer after granulation, maintain the stability and strength of the granules, and improve the storage and transportation performance of the fertilizer.

After granulation, BB fertilizer needs to be cooled by a cooler to prevent nutrient volatilization and granule deformation due to high temperature. The cooled BB fertilizer granules are more stable and can maintain the overall quality.

After granulation and drying, organic fertilizer needs to be cooled by a cooler to keep the granules strong and in shape, avoid agglomeration, and help improve the storage life and application effect of the product.

After granulation and drying, single fertilizers such as ammonium sulfate and potassium chloride are used for rapid cooling by coolers to prevent agglomeration caused by residual heat and ensure that the granules are easy to store and transport.

Slow-release fertilizer needs to be cooled by a cooler during the production process to maintain the granule structure and slow-release function. Through rapid cooling, the surface of the granules is more solid, which helps to prolong the slow-release effect.

The cooler is used to cool in the production of bio-organic fertilizer to protect the active microorganisms therein. This can improve the effect of fertilizers during storage and application, ensuring nutrient and biological activity.

After DAP granulation, the cooler is used to quickly cool down to prevent the granules from becoming brittle or losing strength due to high temperature, ensuring the stability and nutrient content of the fertilizer.

The cooler is used to control the temperature of potassium nitrate after granulation to avoid high temperature affecting the physical properties and chemical stability of the fertilizer. After cooling, the granules are stronger and easier to store for a long time

You can get in touch with us through the following contact information

AddressNo. 2289 Huancheng South Road, Tongxiang, Jiaxing, Zhejiang Province, China. Zip code:314500

Please fill in the sales inquiry form and our sales representatives will be in touch shortly.