What Is Bulk Blending (BB) Fertilizer?

BB fertilizer is a blended fertilizer, which is a compound fertilizer made by mixing two or more single fertilizers in a certain proportion through physical methods. It has a flexible formula and can be customized according to soil conditions and crop fertilizer requirements; it has a complete range of nutrients, including macro, medium and trace elements; it has the advantages of cost reduction and efficiency improvement, environmental protection and safety, and is widely used in various crops and soil conditions. It can be used as base fertilizer or topdressing in a variety of ways.

Why BB Fertilizer Matters in Modern Agriculture?

Blended fertilizers are crucial in modern agriculture because their formulas can be customized on demand and they contain comprehensive nutrients. They can improve fertilizer utilization, reduce costs, reduce environmental pollution, help achieve high and good yields of crops, and meet the diverse needs of different soils and crops.

What is the difference Between BB Fertilizer and Other Types (Granular, Liquid, Compound Fertilizers)

BB fertilizer: It is a compound fertilizer made by mixing two or more single fertilizers in a certain proportion by physical methods. The formula is flexible and can be customized according to different soil and crop needs. It has comprehensive nutrients, can improve fertilizer utilization and reduce waste.

Granular fertilizer: It is usually made into granules by granulating fertilizer raw materials. It has the advantages of good physical properties, easy storage and application, and not easy to agglomerate. It can slowly release nutrients and have a long-lasting fertilizer effect.

Liquid fertilizer: It is a liquid fertilizer made by dissolving nutrients in water. Its advantages are good water solubility, can be quickly absorbed by crops, can be accurately fertilized through irrigation systems or foliar spraying, and improve fertilizer utilization, but storage and transportation are relatively inconvenient.

Compound fertilizer: It refers to a fertilizer containing two or more nutrients. It is made by granulation methods, has high nutrient content, few by-products and good physical properties. It can provide multiple nutrients for crops at the same time, but the nutrient ratio is fixed, which is difficult to meet the special needs of different soils and crops.

In comparison, BB fertilizer is more flexible in formula and can accurately adjust nutrients according to actual conditions; granular fertilizer has good physical properties and long-lasting fertilizer effect; liquid fertilizer has fast absorption and high utilization rate but limited storage and transportation; compound fertilizer has high nutrient content and good physical properties, but the nutrient ratio is relatively fixed. Farmers can choose appropriate fertilizers based on factors such as soil conditions, crop types, planting methods and economic costs.

What is the Production Process of BB Fertilizer?

What are the common raw Materials Used in BB Fertilizer?

Nitrogen fertilizer:

- Urea is a common nitrogen fertilizer raw material. Its nitrogen content is quite high, usually around 46%, which is the highest nitrogen content among solid nitrogen fertilizers. It is an organic nitrogen fertilizer. After being applied to the soil, it needs to be converted into ammonium nitrogen under the action of urease before it can be absorbed and utilized by crops.

- Ammonium sulfate is also one of the commonly used nitrogen fertilizer raw materials. It contains about 21% nitrogen and sulfur, which can provide crops with both nitrogen and sulfur nutrients. However, it is a physiologically acidic fertilizer. When used in acidic soil, it is necessary to use it with alkaline fertilizers or lime to adjust the soil pH.

- Ammonium chloride is also a nitrogen fertilizer raw material. It contains about 25% nitrogen and is a physiologically acidic fertilizer. It should be noted that the chloride ions in ammonium chloride have adverse effects on chlorine-sensitive crops such as tobacco, potatoes, and grapes. It is generally not suitable for use on these crops, but it has a better effect on chlorine-loving crops such as rice.

Phosphate fertilizer:

- Superphosphate is a commonly used raw material for phosphate fertilizer. Its main components are calcium dihydrogen phosphate and calcium sulfate. The effective phosphorus content is usually between 12% and 20%. It is a water-soluble phosphate fertilizer with a fast fertilizer effect, but it has low mobility in the soil and is easily fixed by elements such as iron, aluminum, and calcium in the soil. Therefore, when applying it, it should be applied as concentratedly as possible or mixed with organic fertilizer to improve its utilization rate.

- Heavy superphosphate is also an important raw material for phosphate fertilizer. It has a high phosphorus content, generally 40%-50%, and is a high-concentration water-soluble phosphate fertilizer. Its properties are similar to superphosphate, but it does not contain calcium sulfate, so it has better fertilizer effect than superphosphate and is suitable for various soils and crops.

Potassium fertilizer:

- Potassium chloride is a common raw material for potassium fertilizer, with a potassium content of about 60%. It is a water-soluble potassium fertilizer with a fast fertilizer effect. However, due to the presence of chloride ions, it is not suitable for use on chlorine-sensitive crops and saline-alkali land. When used in acidic soils, lime and organic fertilizers should be applied to neutralize the acidity and prevent soil compaction.

- Potassium sulfate is also a commonly used raw material for potassium fertilizer, with a potassium content of about 50%-52% and sulfur. It is a physiologically acidic fertilizer suitable for various soils and crops, especially for chlorine-sensitive crops and sulfur-loving crops such as cruciferae. However, in paddy fields with strong reducing properties, the sulfate ions in potassium sulfate may be reduced to hydrogen sulfide, which is toxic to the rice root system, so when using it in paddy fields, attention should be paid to drainage and sunning.

What is the Bulk Blending Fertilizer Production Steps?

1. Raw material preparation

- Select raw materials: According to the formula requirements of BB fertilizer, select suitable single fertilizers as raw materials, such as nitrogen fertilizers such as urea, ammonium sulfate, and ammonium chloride, phosphorus fertilizers such as superphosphate and heavy superphosphate, potassium fertilizers such as potassium chloride and potassium sulfate, and trace element fertilizers that may be added. Ensure that the quality of the raw materials meets the production requirements, and all indicators such as nutrient content and impurity content must meet the corresponding standards.

- Raw material inspection: Strictly inspect the purchased raw materials, and use chemical analysis, physical testing and other methods to determine the nutrient content, moisture content, particle size distribution and other parameters of the raw materials to ensure the stability and consistency of the raw material quality. Only raw materials that pass the inspection can enter the production link, and unqualified raw materials must be processed or returned in time.

- Raw material storage: Store the qualified raw materials in special warehouses or storage areas, and store them according to the type, specification, batch, etc. of the raw materials to avoid mixing different raw materials. At the same time, pay attention to the temperature, humidity and other conditions of the storage environment to prevent the raw materials from getting damp, agglomerating or chemically reacting, affecting product quality.

2. Ingredients automatic batching

- Determine the formula: Determine the formula of BB fertilizer according to different crops, different soil conditions and the actual needs of agricultural production. The formula needs to specify the content ratio of various nutrients and the amount of different raw materials used. For example, for a specific crop, it may be necessary to prepare BB fertilizer with a nitrogen, phosphorus and potassium content ratio of 15:15:15. According to the nutrient content of the selected raw materials, calculate the specific amount of each raw material.

- Precise measurement: Use accurate measuring equipment such as electronic scales and measuring buckets to measure various raw materials according to the requirements of the formula. During the measurement process, the error must be strictly controlled to ensure that the amount of each raw material added is accurate. Generally speaking, for macronutrient fertilizers, the measurement error should be controlled within a small range to ensure the stability and accuracy of the nutrient content of the product.

3. Mixing

- Premixing: Preliminary mixing of various measured raw materials can be carried out by horizontal mixers, vertical mixers and other equipment. The purpose of premixing is to make various raw materials initially evenly distributed in a large range, laying the foundation for subsequent fine mixing. During the premixing process, the mixing time and speed should be controlled to avoid excessive mixing resulting in raw material particle breakage or uneven mixing.

- Fine mixing: The premixed materials then enter fine mixing equipment, such as twin-shaft paddle mixers, ribbon mixers, etc., for further mixing. These equipment can achieve uniform mixing of materials on a smaller scale, ensuring that the distribution uniformity of various nutrients in BB fertilizer reaches a high level. The time for fine mixing is usually longer than the premixing time, and needs to be adjusted according to the specific equipment and material conditions.

4. Granulation(optional)

- Choose a granulation method: Choose a suitable granulation method according to the product requirements and production conditions. Common granulation methods include disc granulation, drum granulation, extrusion granulation, etc. Disc granulation is suitable for producing BB fertilizer granules with small particle size and regular shape; drum granulation can produce granules with large particle size and high strength; extrusion granulation does not require the addition of binders, and the material is formed into granules through mechanical extrusion, which is suitable for some occasions with special requirements for binders.

- Adding binders (required for some granulation methods): If disc granulation or drum granulation is used, it is usually necessary to add an appropriate amount of binders, such as bentonite, kaolin, humic acid, etc., to improve the forming rate and strength of the granules. The amount of binder added should be optimized and adjusted according to the properties of the raw materials, the characteristics of the granulation equipment and the quality requirements of the product. Too much or too little binder will affect the quality of the granules.

- Granulation operation: The mixed material is sent into the granulation equipment and granulated according to the selected granulation method and process parameters. During the granulation process, the humidity, temperature, rotation speed and other parameters of the material should be controlled to obtain the ideal particle shape, size and strength. For example, in the disc granulation process, the disc inclination, rotation speed and amount of material added should be adjusted so that the particles can be continuously rolled and formed on the disc.

5. Screening

- Particle screening: The granulated materials are screened by screening equipment such as vibrating screens and rotary screens to classify the particles according to size specifications. Generally, multiple screens are set up to separate oversized or undersized particles that do not meet the product particle size requirements. For example, for BB fertilizers with a particle size of 2-4 mm, particles larger than 4 mm and smaller than 2 mm can be screened out separately by screening.

- Recycling and reprocessing: The oversized particles screened out are usually crushed by equipment such as crushers and then returned to the granulation stage; the undersized particles can be returned to the mixing stage and re-granulated with new materials to improve the utilization rate of raw materials and the quality stability of the product.

6. Coating(Optional)

- The coating process of BB fertilizer is to coat the surface of fertilizer particles with one or more layers of specific substances to regulate the release of fertilizer nutrients and improve fertilizer performance. There are two main purposes of coating. One is to control nutrient release. Coating can slowly release fertilizer nutrients, match the growth rhythm of crops, reduce nutrient loss, and improve fertilizer utilization. The second is to improve fertilizer performance. Coating can prevent fertilizer from absorbing moisture and agglomeration, enhance stability and fluidity, and facilitate storage and application.

- Coating materials cover a variety of types. Inorganic coating materials include sulfur, gypsum, etc. The sulfur coating is gradually decomposed by microorganisms to achieve slow release of nutrients. Gypsum coating can both regulate soil pH and protect fertilizer particles. Common organic coating materials include paraffin, resin, polyethylene, etc. Paraffin prevents water from entering fertilizer particles and delays nutrient dissolution. Resin has good film-forming properties and stability. The coating thickness can be adjusted as needed to control the nutrient release rate. Polyethylene has high strength and water resistance. Biodegradable coating materials, such as starch and chitosan, are environmentally friendly and can be decomposed by microorganisms in the soil, which is in line with the development trend of green agriculture.

- There are various coating processes. Spray coating is to dissolve the coating material into a solvent to make a coating liquid, and then use a spray gun to evenly spray it on the surface of the fertilizer particles. After the solvent evaporates, a thin film is formed. The operation is simple and the coating is uniform, but attention should be paid to the selection and recovery of the solvent. Fluidized bed coating uses fluidized bed equipment to suspend the fertilizer particles in the hot air flow, add the coating material, and heat it on the surface of the particles to melt or solidify it into a film. This process can be produced continuously, with good coating effect, high particle fluidity and surface finish. Dip coating is to immerse the fertilizer particles in the coating material solution or melt to fully adsorb it, and then dry or cool it to solidify the coating material. It is suitable for situations where the coating thickness requirements are high, but the production efficiency is low and the coating uniformity may be poor.

- Coating quality control is extremely critical. The coating thickness can be checked with a microscope or electron microscope to ensure that it meets the design requirements. The uniform and moderate thickness ensures stable and consistent nutrient release. The integrity of the coating can be checked with the naked eye or a magnifying glass to see if there is any damage or cracks. Its integrity is related to the moisture-proof and caking resistance of the fertilizer and the regulation of nutrient release. The nutrient release performance test is carried out according to standard methods, such as soil cultivation method and simulated soil solution immersion method, to measure the nutrient release at different times and evaluate whether the regulation effect of the coating on nutrient release meets the needs of plant growth.

7. Packaging

- Metering and packaging: The qualified BB fertilizer particles after screening are metered and packaged by a packaging machine. The packaging machine can accurately control the weight of each bag of fertilizer. Common packaging specifications include 25 kg, 50 kg, etc. During the packaging process, the accuracy of the packaging weight and the sealing of the packaging must be ensured to prevent the fertilizer from getting damp and deteriorating during storage and transportation.

- Labeling and warehousing: The packaged BB fertilizer bags must clearly indicate the product name, nutrient content, implementation standards, manufacturer, production date, shelf life and other information. Then the packaged fertilizers are neatly stacked and stored in the warehouse for sale and transportation. During storage, attention should be paid to the ventilation, moisture-proof, fire-proof and other conditions of the warehouse to ensure that product quality is not affected.

What are the Key Equipment in BB Fertilizer Production?

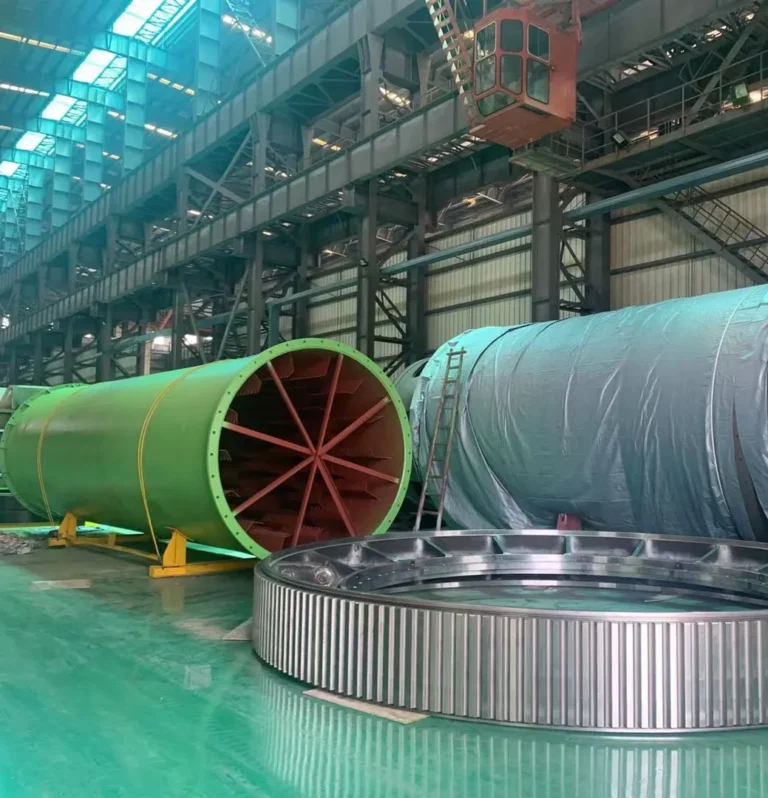

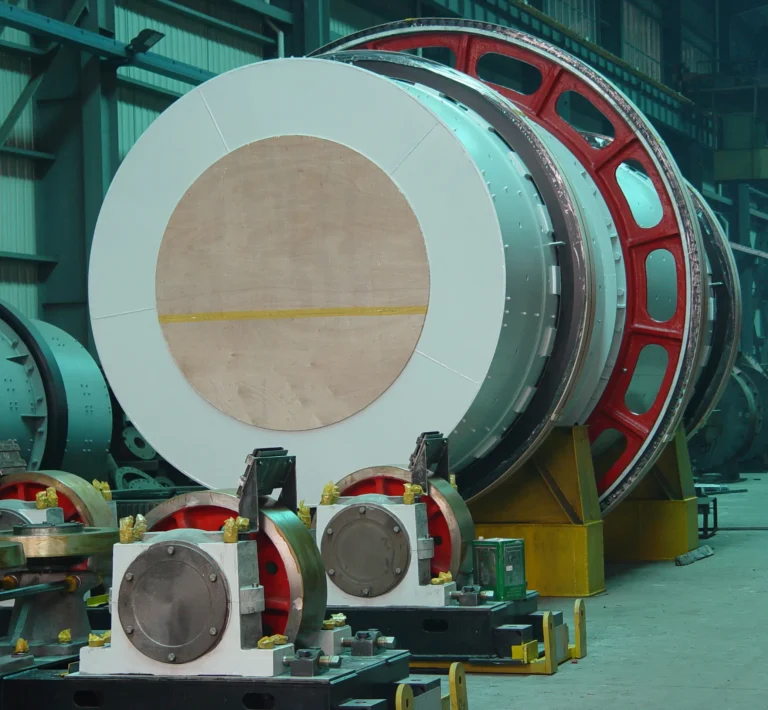

What is TONGLI Bulk Blending Fertilizer Production Line?

- Tongli Heavy Machinery's BB fertilizer production line is a set of professional equipment systems designed for the efficient production of BB fertilizers. Starting from the raw material processing link, the production line quickly and accurately screens and pre-processes various nitrogen fertilizers, phosphate fertilizers, potash fertilizers and other raw materials to ensure that the proportion of raw materials put into production meets the standards.

- In the core batching stage, with the help of advanced intelligent weighing and automatic control systems, the proportion of each raw material can be adjusted with extremely high precision according to different formula requirements, and the error is controlled within a very small range.

- The mixing process uses independently developed mixing technology to achieve uniform mixing of multiple raw materials in a short time. For production scenarios with granulation requirements, the production line is equipped with a uniquely designed granulation device that can shape fertilizer particles with regular shapes and appropriate strength.

- In addition, in the coating link, the innovative DCS spray coating technology is used to stably cover the surface of the fertilizer particles with a uniform and firm coating, effectively controlling the nutrient release rate. The entire production line is highly automated, and each process is closely connected to ensure that the quality of each batch of BB fertilizer products is stable and reliable

What are the Essential Machinery in BB Fertilizer Manufacturing?

1. Raw material storage equipment

Raw material warehouse: used to store various basic fertilizer raw materials, such as urea, diammonium phosphate, potassium chloride, potassium sulfate, etc. The raw material warehouse generally adopts steel structure or concrete structure, with a certain volume and sealing to prevent the raw materials from getting damp, agglomerating and deteriorating. According to the type of raw materials and production scale, multiple different raw material warehouses can be set up to classify, store and manage different raw materials.

2. Batching equipment

- Electronic batching scale: This is the key batching equipment in the BB fertilizer production line. It uses high-precision weighing sensors to accurately weigh and measure various raw materials, and accurately batches different raw materials according to the preset formula ratio. The electronic batching scale has the advantages of high weighing accuracy, good stability, and fast response speed. It can realize automatic batching and greatly improve the accuracy and production efficiency of batching.

- Batching controller: used in conjunction with the electronic batching scale, it is responsible for controlling and managing the batching process. It can automatically control the batching amount of each raw material according to the preset formula parameters to achieve accurate proportions of multiple raw materials. At the same time, the batching controller also has functions such as data recording, printing, and alarm, which facilitates the monitoring and management of the production process.

3. Mixing equipment

- Horizontal ribbon mixer: It is one of the commonly used mixing equipment in BB fertilizer production. There are two counter-rotating ribbons inside, which can make the material flow in the horizontal and vertical directions at the same time, so as to achieve fast and uniform mixing. The horizontal ribbon mixer has the advantages of high mixing efficiency, good mixing uniformity, and large loading coefficient. It is suitable for mixing various granular and powdery materials.

- Double-shaft paddle mixer: This mixer has multiple paddles installed on the two shafts, and the materials are mixed by the rotation of the paddles. The double-shaft paddle mixer has a fast mixing speed and good mixing effect, and can mix different raw materials evenly in a short time. At the same time, it also has the characteristics of compact structure, small footprint, and easy maintenance.

4. Coating equipment (optional)

- Fluidized bed coating machine: Using fluidized bed technology, the fertilizer particles are suspended under the action of hot air flow, and then the coating material is added to the fluidized bed in the form of liquid or powder. The coating material melts or solidifies on the surface of the particles under heat to form a uniform coating. The fluidized bed coating machine has the advantages of uniform coating, good particle fluidity, and high production efficiency, and can effectively control the release rate of fertilizer nutrients.

- Spray coating machine: The coating material is dissolved in a solvent to make a coating liquid, and the coating liquid is evenly sprayed on the surface of the fertilizer particles through a spray device. As the solvent evaporates, the coating material forms a thin film on the surface of the particles. The spray coating machine is flexible in operation, and the coating thickness and type of coating material can be adjusted according to needs. It is suitable for coating treatment of different types of BB fertilizers.

5. Conveying equipment

- Belt conveyor: conveys materials by the rotation of the belt, with the advantages of large conveying capacity, long conveying distance, stable operation and low noise. In the BB fertilizer production line, belt conveyors are often used to convey raw materials from storage bins to batching equipment, and to convey finished fertilizers from packaging equipment to warehouses or transport vehicles.

- Bucket elevator: used to lift materials vertically, lifting materials from a lower position to a higher position. The bucket elevator consists of a bucket, a traction chain or belt, a drive device, a tensioning device and other parts. It has the advantages of compact structure, small footprint and large lifting height, and is suitable for lifting and conveying various granular and powdery materials.

6. Packaging equipment

Automatic quantitative packaging scale: used for quantitative packaging of finished BB fertilizer. It uses high-precision weighing sensors and advanced control algorithms to quickly and accurately complete the weighing and packaging of each bag of fertilizer. The automatic quantitative packaging scale has the advantages of high packaging accuracy, fast packaging speed, and simple operation. Different packaging weights can be set according to user needs.

Sealing machine: seal the packaged fertilizer bags. Common sealing machines include heat sealing machines and sewing machines. Heat sealing machines melt and bond the sealing part of the packaging bag by heating, which is suitable for sealing plastic packaging bags; sewing machines sew the opening of the packaging bag together through needle and thread, which is suitable for packaging bags of various materials, with firm sealing and good sealing.

What are the Advantages and Disadvantages of BB(Bulk Blending) Fertilizer?

Adventages:

- Flexible nutrient supply: BB fertilizer is made by mixing various single fertilizers (such as urea, diammonium phosphate, potassium chloride, etc.) in a certain proportion according to the nutrient requirements of different crops and different soils. Therefore, it can flexibly adjust the nutrient ratio according to the actual situation, accurately meet the needs of crops for nitrogen, phosphorus, potassium and other trace elements at different growth stages, and achieve scientific fertilization.

- Strong targeted formula: personalized formulas can be formulated according to the soil fertility conditions and crop types in different regions. For example, for phosphorus-deficient soils, the proportion of phosphorus fertilizer can be appropriately increased in the BB fertilizer formula; for potassium-loving crops such as tobacco and potatoes, the content of potassium fertilizer can be increased. This targeted formula design can effectively improve the utilization rate of fertilizers and avoid nutrient waste.

- Good physical properties: BB fertilizer is generally a mixture of fertilizer particles with uniform particle size and regular shape, with good fluidity and air permeability. This helps the fertilizer to be evenly distributed in the soil, allowing the roots to fully contact and absorb nutrients. At the same time, good physical properties also facilitate fertilization operations, and mechanical fertilization can be used to improve fertilization efficiency.

- Balanced nutrient release: Since the various nutrients in BB fertilizer are physically mixed, the release rate of different nutrients in the soil is relatively stable and balanced. This enables crops to continue to obtain a stable supply of nutrients throughout the growth cycle, avoiding problems such as poor growth or quality degradation caused by too fast or too slow supply of certain nutrients.

- Low production cost: Compared with some compound fertilizers, the production process of BB fertilizer is relatively simple and does not require a complex granulation process, so the production cost is low. At the same time, since it is formulated according to actual needs, some unnecessary nutrient additions are avoided, and the cost of fertilizers is also reduced. For farmers, this can reduce fertilization costs and improve economic benefits while ensuring the fertilization effect.

- Environmentally friendly: Reasonable formula enables BB fertilizer to accurately meet crop needs, reduce nutrient loss caused by excessive fertilization, and thus reduce the risk of pollution to water bodies, soil and other environments. For example, precise nitrogen supply can reduce nitrate leaching and ammonia volatilization caused by excessive nitrogen fertilizer, which has positive significance for environmental protection.

- Significant fertilizer effect: BB fertilizer can accurately supply nutrients according to crop needs, make crops grow strong, and improve the quality of agricultural products while increasing crop yields. For example, a reasonable ratio of nitrogen, phosphorus and potassium helps to increase the sugar content of fruits and the vitamin content of vegetables, making agricultural products more competitive in the market.

- Convenient application: BB fertilizer can be packaged and applied according to different fertilization methods and crop planting patterns. Whether it is used for broadcasting and strip application of field crops, or for hole application and drip irrigation of cash crops, it can be easily operated and adapted to a variety of agricultural production scenarios.

- Trace elements can be added: When producing BB fertilizer, various trace elements such as zinc, iron, manganese, boron, etc. can be flexibly added according to the needs of soil and crops. These trace elements play an important role in the growth and development, stress resistance and other aspects of crops, and can effectively prevent various physiological diseases caused by the lack of trace elements in crops, and further improve the yield and quality of crops.

- Improve soil structure: The rational use of BB fertilizers can help improve the physical, chemical and biological properties of the soil. For example, an appropriate amount of phosphorus fertilizer can promote the activity of microorganisms in the soil, increase the decomposition and transformation of soil organic matter, and improve soil fertility; potassium fertilizer can enhance the soil's ability to retain water and fertilizer, improve soil aeration and water permeability, and make the soil structure looser, which is conducive to the growth and development of crop roots.

Disadventages:

- Problems with uniform nutrient distribution: BB fertilizer is made by physically mixing single-element fertilizer particles of different particle sizes. During production, transportation and storage, particle separation may occur due to differences in particle size, shape and density, resulting in uneven nutrient distribution in the fertilizer. For example, during loading and unloading and transportation, larger particles may gradually sink, while smaller particles will be relatively concentrated at the top, causing the fertilizer nutrient ratio in different parts to change, affecting the uniformity of the fertilization effect.

- Insufficient stability and long-term effectiveness: The nutrients in BB fertilizer mainly exist in the form of single-element fertilizers. After encountering water in the soil, they will quickly dissolve and release nutrients. Compared with some fertilizers with slow-release or controlled-release functions, BB fertilizer has a faster nutrient release rate and a relatively short fertilizer effect duration. This requires multiple fertilizations according to the growth stage of the crop, which increases the workload and cost of fertilization. Moreover, if the fertilization time is not properly controlled, it may lead to insufficient nutrient supply of crops at certain growth stages, affecting growth and development.

- High requirements for production and use: In terms of production, the formula of BB fertilizer needs to be precisely designed according to the soil fertility, crop types and growth stages in different regions, which requires manufacturers to have professional soil testing and formula design capabilities. At the same time, the mixing process in the production process also needs to be strictly controlled to ensure the uniformity of fertilizer nutrients. In terms of use, farmers need to have a certain understanding of the soil fertility status and crop nutrient requirements in order to reasonably select and use BB fertilizer. If the formula is not properly selected or the fertilization method is incorrect, it will be difficult to give full play to the advantages of BB fertilizer, and it may even lead to poor fertilization effect and affect crop yield and quality.

- Easy to absorb moisture and agglomerate: Some ingredients in BB fertilizer, such as urea and potassium chloride, have strong hygroscopicity. In an environment with high air humidity, BB fertilizer easily absorbs moisture in the air and deliquesces, causing the surface of fertilizer particles to become moist, and then stick to each other and agglomerate. The agglomerated BB fertilizer is not only difficult to spread evenly during fertilization, but also affects the air permeability and nutrient release performance of the fertilizer. Moreover, fertilizers with severe agglomeration may need to be crushed before use, which increases the difficulty and cost of use.

- The quality of market products varies: Since the production process of BB fertilizer is relatively simple and the market entry threshold is low, some small production companies or workshops may use inferior raw materials or not strictly follow the formula to reduce costs, resulting in unstable product quality. In addition, some companies may have illegal behaviors such as falsely labeling nutrient content and selling inferior products as good ones, making it difficult for farmers to distinguish the quality of products when purchasing BB fertilizers, and they are prone to buying poor quality products, which affects the fertilization effect and agricultural production.

What are the BB Fertilizer Formulation Techniques?

How to Create an Effective BB Fertilizer Formula?

1. Soil testing and analysis

- Collecting soil samples: In the target farmland, soil samples are collected multiple times according to certain collection rules, and generally a mixed soil sample is collected every 10-15 mu. The collection depth is usually 0-20 cm to collect typical samples of the plough layer soil.

- Laboratory analysis: Comprehensive nutrient analysis of soil samples, including determination of the content of macroelements (nitrogen, phosphorus, potassium), medium and trace elements (calcium, magnesium, sulfur, iron, zinc, manganese, copper, boron, molybdenum, etc.) in the soil, and analysis of soil acidity (pH value), organic matter content, contaminant exchange capacity (CEC) and other indicators.

2. Understand the nutritional needs of crops

- Differences in the needs of different crops: There are large differences in the variety and quantity of nutrients required by different crops. For example, leafy crops have a relatively prominent demand for potassium to promote crop growth; fruit and vegetable crops have an increased demand for phosphorus and potassium during the fruiting period, which is conducive to the growth and quality improvement of crops; while root and tuber crops have a relatively prominent demand for potassium, which is conducive to the growth of underground rhizomes.

- Changes in the needs of crops at different growth stages: Crops also have different needs for nutrients at different growth stages. Generally speaking, in the seedling stage, crops have a relatively increased demand for nutrients, and are more sensitive to phosphorus. The phosphorus of crops helps the growth and growth of the root system; in the vigorous growth period, crops have a sharp increase in demand for macronutrients such as nitrogen, phosphorus, and potassium; in the reproductive growth stage, such as the flowering and fruiting period, the demand for phosphorus, potassium and some trace elements is more critical.

3. Determine the raw materials of fertilizers

- Macronutrient fertilizers: Commonly used nitrogen fertilizers include urea, ammonium chloride, potassium sulfate, etc.; phosphorus fertilizers include diammonium phosphate, superphosphate, etc.; potassium fertilizers include potassium chloride, potassium sulfate, etc. Appropriate single-element fertilizers can be selected according to soil nutrient conditions and crop needs. For example, if the soil is acidic, alkaline phosphate fertilizers such as calcium magnesium phosphate fertilizers can be preferred to adjust the soil alkalinity; for chlorine-sensitive crops such as tobacco and grapes, potassium sulfate should be used as a source of fertilizer potassium.

- Medium and trace element fertilizers: Select the corresponding fertilizers according to the soil test results and the crop's needs for medium and trace elements. For example, zinc sulfate can be used to supplement zinc, borax can be used to supplement boron, etc. Compound fertilizers or foliar fertilizers containing some multiple medium and trace elements can also be used according to actual conditions.

4. Calculate the formula ratio

- Determine the target yield: Refer to the average yield of similar crops in the local area and the fertility of the farmland to determine a reasonable target yield. The determination of the target yield should take into account a variety of factors, such as variety characteristics, planting density, management level, etc.

- Calculate nutrient requirements: According to the target yield and the nutrient absorption law of the crop, calculate the outline of various nutrients required for the crop to achieve the target yield. Generally speaking, for every 100 kg of wheat produced, about 3 kg of nitrogen, 1.25 kg of phosphorus, and 2.5 kg of potassium need to be absorbed; for every 100 kg of corn produced, 2.5 - 3 kg of nitrogen, 1 - 1.5 kg of phosphorus, and 2 - 2.5 kg of potassium need to be absorbed. The nutrient absorption of different crops and varieties will vary. You can refer to relevant agricultural technical information or local fertilization experience.

- Consider the soil fertility supply capacity: calculate the amount of nutrients that the soil can provide for crops based on the content of various nutrients in the soil and the effective utilization rate of soil nutrients. Generally speaking, the utilization rate of nitrogen in the soil in the current season is 40% - 60%, the utilization rate of phosphorus fertilizer is 10% - 25%, and the utilization rate of potassium is 40% - 50%. The nutrients of high-yield plants and the amount of fertilizer supplied by groundwater can be obtained through the nutrients supplemented by fertilization.

- Determine the fertilizer formula: calculate the application amount of various fertilizers based on the nitrogen nutrients to be supplemented and the nutrient content of the selected fertilizer. For example, if 15 kg/mu of nitrogen is required and urea (nitrogen content 46%) is used as the source of nitrogen fertilizer, the application amount of urea is 15÷0.46≈32.6 kg/mu. According to the above method, the application amount of phosphate fertilizer, potassium fertilizer and medium and trace element fertilizer is calculated to determine the formula of BB fertilizer.

5. Formula adjustment and optimization

- Field test verification: The initially determined fertilizer formula is tested in a small field, and different fertilization treatments are set, including control treatment (no fertilization or frequent fertilization), to observe the growth, yield performance, and quality indicators of crops. By analyzing the test data, the rationality and effectiveness of the formula are evaluated. If problems are found, the formula is adjusted in time.

- Long-term monitoring and dynamic adjustment: Soil fertility and crop requirements will change with time and changes in planting systems, so long-term monitoring of soil and crops is required. Soil tests are conducted every year before fertilization, and the fertilizer formula is dynamically adjusted according to the changes in soil nutrients and the growth of crops to ensure the moisture and fertilizer of the formula. At the same time, pay attention to the development of agricultural production technology and the promotion of new varieties, promptly incorporate new technology and variety information into the formulation considerations, and continuously optimize the BB fertilizer formula.

5 Key Considerations for Uniform Blending

1. Choose the right mixing equipment

- Double-shaft paddle mixer: It has the characteristics of multi-directional stirring blades, which can make the materials form a complex motion trajectory in the mixing barrel, with both non-axial convection mixing and axial tumbling mixing, good mixing effect, high uniformity, and can effectively ensure the full mixing of various raw materials in BB fertilizer.

- V-type mixer: Its unique V-shaped structure enables the materials to produce strong convection and diffusion effects when mixing. The materials alternately tumble in the two conical barrels, flowing from one barrel to the other, achieving rapid and uniform mixing, which is often used in BB fertilizer production with high requirements for mixing uniformity.

2. Optimize mixing process parameters

- Determine a reasonable mixing time: If the mixing time is too short, the materials cannot be fully mixed, resulting in poor uniformity; if the mixing time is too long, it will not only increase energy consumption and equipment wear, but also may cause segregation of the mixed materials. Generally speaking, depending on different mixing equipment and production scales, the mixing time is usually controlled between 10 and 30 minutes.

- Control the appropriate filling rate: The filling rate refers to the filling degree of the material in the mixing equipment. If the filling rate is too high, the movement space of the material during the mixing process is limited and it cannot be fully turned over, which affects the mixing effect; if the filling rate is too low, the equipment utilization rate is low, and the material is prone to excessive throwing and segregation during mixing. Generally, it is more appropriate to control the filling rate of the mixing equipment at 40% - 60%.

3. Strictly control the particle size of raw materials

- Screening raw materials: Before production, various raw materials are strictly screened to ensure that their particle size distribution is within a certain range. For example, for major raw materials such as urea, potassium chloride, and diammonium phosphate, the particle size should be kept consistent as much as possible, generally controlled between 2-4 mm, to reduce the separation phenomenon caused by particle size differences and improve mixing uniformity.

- Crushing and screening: For raw materials with larger particle sizes, they are crushed by a crusher and then screened by screening equipment such as a vibrating screen to ensure that the particle size of the raw materials meets the mixing requirements. For raw materials with too small particle sizes, granulation treatment can be appropriately performed to ensure the fluidity and uniformity of the raw materials during the mixing process.

4. Adopt a reasonable order of adding materials

- Add basic fertilizer first: Add the basic fertilizers that account for a large proportion, such as urea and potassium chloride, to the mixing equipment first, so that they form a uniform bottom material layer in the equipment, providing a stable mixing basis for the subsequent addition of other fertilizers.

- Add trace element fertilizers later: Since trace element fertilizers are used in small quantities, in order to ensure their uniform distribution in BB fertilizers, they should be added after the basic fertilizers are mixed for a period of time. This can avoid the concentration of trace element fertilizers in local areas and ensure that they are evenly dispersed in the entire fertilizer system.

5. Set up quality inspection method

- Regular sampling and testing: During the production process, samples are regularly taken from the mixed fertilizers for nutrient content and uniformity testing. Through chemical analysis and other methods, the content of major nutrients such as nitrogen, phosphorus, and potassium in the samples is determined and compared with the formula requirements. At the same time, the uniformity of the fertilizer particles is checked to promptly discover possible problems in the mixing process.

- Adjust mixing parameters: Based on the test results, if it is found that the fertilizer uniformity does not meet the requirements, timely analyze the reasons and adjust the mixing process parameters, such as extending the mixing time, adjusting the filling rate or checking the raw material particle size, to ensure that the quality of the fertilizer produced subsequently meets the standards.

Quality Control and Testing in BB Fertilizer Production

Essential Quality Standards for BB Fertilizer

1. Appearance

- Particle uniformity: High-quality BB fertilizer particles are uniform in size and regular in shape, without obvious large or small particle aggregation. Such particles can be evenly distributed during fertilization, which is conducive to the balanced absorption of nutrients by crops.

- Color: Under normal circumstances, the color of BB fertilizer is uniform. If the surface color of the fertilizer is gray, has variegated colors, or the color is too bright and unnatural, it may be that inferior raw materials or pigments were added during the production process to cover up quality problems.

2. Nutrient content

- Total nutrient content: According to national standards, the total nutrient content of BB fertilizer (N + P₂O₅ + K₂O) should not be lower than the marked value. For example, the actual test value of BB fertilizer marked with a total nutrient content of 45% should be 45% or above.

- Single nutrient content: The content of each single nutrient (nitrogen, phosphorus, potassium) must also comply with the product marked value, and the deviation should be within the allowable range. Generally speaking, the allowable deviation of the single nutrient content of nitrogen, phosphorus, and potassium is ±1.5%. For example, if the product indicates that the nitrogen content is 15%, the actual test value should be between 13.5% and 16.5%.

- Trace element content: For BB fertilizers with added trace elements (such as zinc, boron, iron, etc.), the trace element content should also meet the requirements of the product labeling to ensure that the fertilizer can provide comprehensive nutrition for crops.

3. Physical properties

- Moisture content: Excessive moisture content will cause BB fertilizers to agglomerate and have poor fluidity, affecting the fertilization effect and may also cause nutrient loss. Generally, the moisture content of BB fertilizers should be controlled between 2% and 5%.

- Particle strength: High-quality BB fertilizer particles have high strength and are not easy to break and pulverize. During transportation and storage, the integrity of the particles can be maintained, reducing nutrient loss and dust pollution. The particle strength can be preliminarily judged by a simple extrusion or friction test, such as gently pressing the particles with your fingers. If they are not easy to break, it means that the strength is good.

4. International Fertilizer Industry Association (IFA) Standards

- Nutrient content labeling: requires clear and accurate labeling of the content of nitrogen (N), phosphorus (P₂O₅), potassium (K₂O), and other important nutrients such as medium-sized elements (calcium, magnesium, sulfur, etc.) and trace elements (zinc, iron, manganese, copper, boron, molybdenum, etc.). For example, the product label is "N - P₂O₅ - K₂O = 15 - 15 - 15 + TE", where "TE" indicates the presence of trace elements.

- Particle characteristics: There are certain requirements for the size distribution, shape and strength of the particles. Generally, the particle size is required to be uniform, and the particle size range is usually between 2-5 mm to ensure uniform fertilization and good fluidity. The particle shape should be as regular as possible to reduce agglomeration during storage and transportation. The particle strength should be high enough to withstand a certain amount of pressure and friction to avoid breakage and pulverization during transportation.

- Moisture content: The moisture content of BB fertilizer is generally not more than 2% to prevent the fertilizer from caking due to excessive moisture, reducing nutrient effectiveness or causing other quality problems.

5. European Committee for Standardization (CEN) Standard

- Heavy metal limit: Strictly limit the content of heavy metals in fertilizers, such as lead (Pb), cadmium (Cd), mercury (Hg), arsenic (As), etc. To protect the soil environment and crop safety, and prevent heavy metals from accumulating in the soil and causing harm to the ecosystem and human health. For example, the content of cadmium is usually limited to no more than 10 mg/kg.

- Nutrient uniformity: It is required that the distribution uniformity of each nutrient in BB fertilizer is good throughout the product. Through specific detection methods, such as multi-point sampling analysis, ensure that the difference in nutrient content in fertilizer samples from different parts is within the allowable range, and the general coefficient of variation does not exceed 5%.

6. AOAC Standards

- Analysis methods: A series of accurate and reliable fertilizer nutrient analysis methods are provided, including Kjeldahl nitrogen determination method for nitrogen content, quinoline phosphomolybdate gravimetric method for phosphorus content, and potassium tetraphenylborate gravimetric method for potassium content. These methods provide unified technical specifications for accurate detection of nutrient content in BB fertilizers, ensuring the accuracy and comparability of test results.

- Packaging labeling: It is required to clearly mark the product name, nutrient content, manufacturer, production date, shelf life and other information on the fertilizer packaging. At the same time, it is also necessary to indicate the applicable crop types, fertilization methods and precautions, so that users can use fertilizers correctly.

7. Other aspects

- Chloride ion content: For crops that avoid chlorine (such as tobacco, potatoes, grapes, etc.), low-chlorine or chlorine-free BB fertilizers should be used. Generally speaking, the chloride ion content in BB fertilizers should be controlled according to crop needs and soil conditions. For crops that avoid chlorine, the chloride ion content is usually required to be less than 3%.

- Water solubility: BB fertilizer should have good water solubility and be able to dissolve quickly in the soil, releasing nutrients for crops to absorb. Put an appropriate amount of BB fertilizer into water, stir it and observe the dissolution. High-quality fertilizer should dissolve quickly without obvious precipitation or insoluble matter.

Best Practices for Quality Assurance

- Raw material selection: Select high-quality basic fertilizer raw materials, such as high-purity urea, diammonium phosphate, potassium chloride, etc. Ensure that the nutrient content of the raw materials meets the standard, has few impurities, and meets the relevant quality standards. At the same time, the raw materials are strictly tested for quality, including nutrient analysis, moisture content determination, heavy metal content detection, etc., to ensure the quality of the fertilizer from the source.

- Formula design: According to the needs of different crops, soil conditions and target yields, a scientific and reasonable fertilizer formula is formulated. Accurately calculate the proportion of various nutrients to ensure that the content of nitrogen, phosphorus, potassium and trace elements meets the needs of crop growth, while avoiding nutrient waste or excessive application to pollute the environment.

- Production process control: During the production process, the process parameters of each link must be strictly controlled. For example, in the mixing process, the fertilizer particles must be mixed evenly, and efficient mixing equipment and reasonable mixing time, speed, etc. can be used; in the granulation process, the temperature, humidity and pressure conditions must be controlled to obtain fertilizer products with uniform particle size and appropriate strength; in the drying process, ensure that the appropriate amount of water is removed so that the moisture content of the fertilizer meets the standard requirements.

- Quality inspection and monitoring: Establish a complete quality inspection system and conduct regular inspections on semi-finished products and finished products during the production process. Inspection items include nutrient content, moisture content, particle size, strength, pH, etc., to promptly discover and solve quality problems that occur during the production process. At the same time, use advanced testing equipment and technology to improve the accuracy and efficiency of inspections.

- Packaging and storage: Select appropriate packaging materials, such as moisture-proof, sun-proof, and pressure-resistant packaging bags to protect fertilizers from moisture, agglomeration, and nutrient loss during storage and transportation. The storage environment should be kept dry and ventilated to avoid contact between fertilizers and humid air, water sources, or other harmful substances to prevent the quality of fertilizers from deteriorating.

- Traceability system construction: Establish a product traceability system to record the entire process information of fertilizer production, including raw material procurement, production batches, production time, quality inspection results, sales destinations, etc. In this way, when quality problems occur, the source of the problem can be quickly traced back and effective measures can be taken to deal with it. At the same time, it also helps to improve the management level of the enterprise and the controllability of product quality.

- Personnel training and management: Strengthen the training of production personnel, quality inspection personnel, and management personnel to improve their professional quality and quality awareness. Make them familiar with the production process, quality standards and operating specifications, and be able to strictly carry out production and quality control in accordance with the requirements to ensure that each link meets the requirements of quality assurance.

- Continuous improvement: Regularly evaluate and analyze product quality, collect user feedback information, and understand the effects and problems of fertilizers in actual use. Based on this information, optimize and improve the production process, formula, etc., and continuously improve product quality to meet the needs of the market and users.

Application of BB Fertilizer in Agriculture

How to Apply BB Fertilizer Correctly?

1. Fertilize according to crop needs

- Nutrient demand characteristics of different crops: Different crops have different proportions and quantities of nitrogen, phosphorus, potassium and other trace elements. For example, leafy crops such as cabbage and spinach require a large amount of nitrogen to promote leaf growth; fruit and vegetable crops such as tomatoes and cucumbers have a higher demand for phosphorus and potassium during the fruiting period, which helps the development and quality of the fruit; root crops such as radishes and potatoes have a relatively high demand for potassium, which is conducive to the expansion of underground rhizomes.

- Adjust the amount of fertilizer according to the growth stage of the crop: The demand for nutrients of crops also changes at different growth stages. Generally speaking, in the seedling stage of crops, the demand for nutrients is relatively small, but the supply of nutrients is more sensitive. At this time, an appropriate amount of quick-acting nutrients should be provided to promote the root development of seedlings and the growth of the aboveground parts. As the crops grow, they enter the vigorous growth period and reproductive growth period, and the demand for nutrients gradually increases, and the amount of fertilizer needs to be increased to meet the needs of crop growth and development. For example, rice has a greater demand for nitrogen, phosphorus, and potassium during the tillering and booting stages, and appropriate topdressing should be applied according to soil fertility and seedling conditions.

2. Fertilize according to soil fertility

- Soil nutrient content determination: Before fertilization, the soil nutrient content should be determined to understand the content levels of nitrogen, phosphorus, potassium and other trace elements in the soil. Through soil testing, it is possible to determine which nutrients in the soil are in sufficient supply and which are lacking, so as to select the formula and amount of BB fertilizer in a targeted manner. For example, if the content of quick-acting phosphorus in the soil is high, the proportion of phosphorus fertilizer can be appropriately reduced when selecting BB fertilizer to avoid waste and environmental pollution caused by excessive application of phosphorus fertilizer.

- Soil texture and fertilizer retention: Soils of different textures have different fertilizer retention and supply capabilities. Sandy soil has good air permeability, but poor fertilizer and water retention capabilities, and fertilizer is easy to lose. Therefore, when fertilizing, a small amount of multiple fertilization methods should be adopted, and BB fertilizers with faster nutrient release should be selected to reduce nutrient loss. Clay soil has strong fertilizer and water retention capacity, but poor air permeability. When applying fertilizer, attention should be paid to increasing the application amount of organic fertilizer, improving soil structure, and selecting BB fertilizer with larger particles and better air permeability to improve fertilizer utilization. Loamy soil has the advantages of both sandy soil and clay soil, and is a more ideal soil texture. When applying fertilizer, you can choose the appropriate BB fertilizer and fertilization method according to crop needs and soil nutrient conditions.

3. Determine the reasonable amount of fertilizer

- Calculate the amount of fertilizer based on the target yield: According to the target yield of the crop and the soil fertilizer supply capacity, calculate the amount of nutrients that need to be supplemented, so as to determine the amount of BB fertilizer. Generally speaking, the higher the target yield, the greater the nutrient supply required. For example, to produce 1,000 kg of rice, it is necessary to absorb approximately 16-25 kg of nitrogen, 5-10 kg of phosphorus, and 14-20 kg of potassium. In actual fertilization, factors such as soil fertilizer supply capacity and fertilizer utilization rate need to be considered, and the specific amount of fertilizer should be determined by the fertilizer amount calculation formula.

- Recommended dosage of reference fertilizer: Fertilizer manufacturers usually give recommended fertilizer dosage ranges on product packaging or in product instructions according to different crops and soil types. These recommended dosages are based on a large number of field tests and production practices and have certain reference value. In actual fertilization, the recommended dosage can be appropriately adjusted in combination with local soil fertility conditions, crop varieties, and planting density.

4. Choose a suitable fertilization method

- Application of base fertilizer: When BB fertilizer is used as base fertilizer, it should be applied to the soil before sowing or transplanting crops. Generally, the method of strip application or hole application is adopted to evenly apply the fertilizer to the planting ditch or planting hole, and then fully mix it with the soil before sowing or transplanting. The application amount of base fertilizer generally accounts for 50% - 70% of the total fertilization amount, and the specific proportion depends on the type of crop and soil fertility. For example, for gramineous crops such as wheat and corn, the application amount of BB fertilizer in the base fertilizer can account for 60% - 70% of the total fertilizer application; for economic crops such as vegetables, the application amount of base fertilizer can account for 50% - 60% of the total fertilizer application.

- Topdressing: Topdressing is the supplementary fertilization during the growth period of crops according to the growth conditions and nutrient requirements of crops. Topdressing can be applied by furrow application, hole application, broadcast application or foliar spraying. Furrow application and hole application are to apply fertilizer to the soil near the root system of crops and then cover the soil. This method has a high fertilizer utilization rate, but the operation is relatively troublesome. Broadcasting is to evenly spread fertilizer on the soil surface, and then combine intertillage or irrigation to integrate the fertilizer into the soil. It is suitable for large-scale fertilization, but the fertilizer utilization rate is relatively low. Foliar spraying is to spray the diluted BB fertilizer solution on the leaves of crops, and absorb nutrients through the leaves. This method is suitable for supplementing trace elements or when the root absorption capacity decreases in the late stage of crop growth. It can quickly meet the crop's demand for nutrients, but the concentration and time of spraying need to be strictly controlled to avoid leaf burns.

5. Pay attention to the time and environment of fertilization

- Fertilization time: The fertilization time should be determined according to the growth law and climatic conditions of the crop. Generally speaking, basal fertilizer should be applied before crop planting in autumn or spring to provide the nutrients required for the early growth of crops. Topdressing should be applied in time according to the growth stage and fertilizer requirements of the crop. For example, for fruit trees, topdressing before flowering can promote flower bud differentiation and flowering and fruiting, and topdressing during the fruit expansion period can promote fruit expansion; for rice, topdressing during the tillering period can promote tillering, and topdressing during the booting period can increase the number of spikelets and grain weight. In addition, fertilization should be avoided under adverse weather conditions such as high temperature, drought or rainy days to avoid affecting the effect of fertilizers and causing nutrient loss.

- Fertilization environment: When applying fertilizer, you should pay attention to the humidity and temperature of the soil. When the soil is too dry, the fertilizer is difficult to dissolve and be absorbed by the crops. At this time, you should water it before fertilizing; when the soil humidity is too high, the fertilizer is easy to be lost with the water, and the fertilization time should be appropriately postponed. At the same time, temperature will also affect the conversion of fertilizers and the absorption of crops. Generally, within the appropriate temperature range (such as 20-30℃), the effectiveness of fertilizers is higher and crops absorb nutrients better. In addition, you should avoid applying alkaline fertilizers in alkaline soils and acidic fertilizers in acidic soils to avoid reducing the effectiveness of fertilizers.

Factors Influencing BB Fertilizer Efficiency

1. Fertilizer’s own factors

1.1 Nutrient content and ratio:

BB fertilizer is composed of macroelements such as nitrogen, phosphorus, potassium and other macroelements in different proportions, as well as trace elements that may be added. Its nutrient content and ratio need to match the needs of crops and the nutrient status of the soil. For example, leafy vegetables require high nitrogen. If the nitrogen content in BB fertilizer is insufficient, it will be difficult to meet their growth needs, affecting the growth and quality of leaves; and for some fruit trees with high potassium requirements, such as bananas, if the potassium ratio in BB fertilizer is unreasonable, it may lead to poor fruit development, reduced yield and quality.

1.2 Fertilizer particle characteristics:

- The size, shape and uniformity of the particles will affect the fertilizer effect of BB fertilizer. If the particles are too large, the contact area with the soil is small, and the nutrient release rate is slow, which may not be able to meet the nutrient needs of crops in the early stage of growth in time; if the particles are too small, they are easy to agglomerate, and it is easy to cause excessive local nutrient concentration during fertilization, which may cause damage to the root system of crops. In addition, poor particle uniformity will lead to uneven distribution of fertilizer in the soil, affecting the balanced absorption of nutrients by crops.

- Fertilizer stability: BB fertilizer should have good stability during storage and application to avoid moisture, high temperature and other environmental factors that cause nutrient volatilization, loss or chemical reaction, thereby reducing fertilizer efficiency. For example, some BB fertilizers containing ammonium nitrogen are easily converted into ammonia volatilization in a hot and humid environment, thereby reducing the nitrogen content and fertilizer efficiency of the fertilizer.

2. Soil factors

2.1 Soil Fertility:

The nutrient content, texture, pH value, etc. of the soil itself will affect the fertilizer effect of BB fertilizer. If the soil fertility is high and it is rich in nutrients such as nitrogen, phosphorus, and potassium, then the amount of BB fertilizer should be appropriately reduced when applying it, otherwise it may cause nutrient excess, leading to problems such as crop leggy growth and aggravation of pests and diseases, and will also cause fertilizer waste and environmental pollution. On the contrary, poor soil needs to select BB fertilizer with appropriate formula according to its nutrient deficiency, and appropriately increase the amount of fertilizer.

2.2 Soil texture:

Soils of different textures have different adsorption, storage and fertilizer supply capabilities for BB fertilizer. Sandy soil has larger particles, large porosity, good air permeability, but poor water and fertilizer retention capacity. After BB fertilizer is applied, nutrients are easily lost with water, and the fertilizer effect lasts for a short time. Therefore, when applying BB fertilizer on sandy soil, a small amount of multiple fertilization methods should be adopted to improve fertilizer utilization. Clay soil has fine particles, small porosity, strong water and fertilizer retention capacity, but poor aeration, slow diffusion of fertilizer in the soil, and relatively slow nutrient release. When fertilizing on clay soil, attention should be paid to improving soil aeration, and BB fertilizer with larger particles and better aeration can be selected to promote nutrient release and crop absorption.

2.3 Soil pH:

The pH of the soil will affect the effectiveness of nutrients in BB fertilizer. For example, in acidic soil, the solubility of elements such as iron and aluminum increases, which may have a toxic effect on crops. At the same time, phosphorus easily combines with iron and aluminum to form insoluble phosphates, reducing the effectiveness of phosphorus. In alkaline soil, the effectiveness of elements such as calcium and magnesium increases, which may lead to a decrease in the effectiveness of some trace elements in the soil, such as zinc, iron, and manganese. Therefore, it is necessary to select a suitable BB fertilizer formula according to the pH of the soil, or to improve the fertilizer efficiency of BB fertilizer by adjusting the pH of the soil.

3. Crop factors

3.1 Crop types:

Different crops have very different nutrient requirements, quantities, and proportions. For example, gramineous crops such as wheat and corn have relatively balanced requirements for nitrogen, phosphorus, and potassium, and generally have greater nutrient requirements during key growth periods such as the jointing stage and the booting stage. Leguminous crops have the ability to fix nitrogen and have relatively less demand for nitrogen fertilizers, but are more sensitive to trace elements such as phosphorus, potassium, molybdenum, and boron. Therefore, different formulas of BB fertilizers should be selected for different crops to meet their specific nutrient requirements and improve fertilizer efficiency.

3.2 Crop growth stage:

Crops have different nutrient requirements at different growth stages. In the seedling stage, the root system of crops is not fully developed, the ability to absorb nutrients is weak, and the demand for nutrients is relatively small, but the supply of nutrients is more sensitive. At this time, it is necessary to provide an appropriate amount of quick-acting nutrients to promote the growth of the root system and aboveground parts of the seedlings. As the crops grow, they enter the vigorous growth period and the reproductive growth period, and the demand for nutrients gradually increases, and the amount of fertilizer needs to be increased to meet the needs of crop growth and development. For example, the demand for nutrients such as phosphorus and potassium increases significantly during the key growth stages of fruit trees, such as the flower bud differentiation period and the fruit expansion period. At this time, the reasonable application of BB fertilizer can promote flower bud differentiation, fruit expansion and quality improvement.

4. Fertilization methods and environmental factors

- Fertilization time: Fertilization time has an important influence on the fertilizer effect of BB fertilizer. Base fertilizer should be applied before crop sowing or transplanting to provide the nutrients required for crop growth in the early stage and lay a good foundation for crop growth. Topdressing needs to be applied in time according to the growth stage and fertilizer requirement of the crop. If the fertilization time is inappropriate, fertilization too early or too late may cause the crop to fail to absorb nutrients in time, affecting the fertilizer effect. For example, excessive fertilization during the flowering period of fruit trees may cause falling flowers and fruits; and failure to fertilize in time after fruit picking will affect the nutrient accumulation of the tree and the yield in the next year.

- Fertilization methods: Common fertilization methods include strip fertilization, hole fertilization, broadcast fertilization, foliar spraying, etc. Different fertilization methods will affect the distribution of BB fertilizer in the soil and the efficiency of crop nutrient absorption. Strip application and hole application can concentrate fertilizer near the root system of crops, reduce the contact area between fertilizer and soil, reduce nutrient fixation and loss, and improve fertilizer utilization rate, but the operation is relatively troublesome and suitable for small-scale planting or cash crops. Broadcasting is to spread fertilizer evenly on the soil surface, and then combine tillage or irrigation to integrate fertilizer into the soil. This method is easy to operate and suitable for large-scale fertilization, but the fertilizer utilization rate is relatively low and it is easy to cause nutrient loss. Foliar spraying is to spray the diluted BB fertilizer solution on the leaves of crops, and absorb nutrients through the leaves. It is suitable for supplementing trace elements or when the root absorption capacity decreases in the late stage of crop growth. It can quickly meet the nutrient needs of crops, but the concentration and time of spraying need to be strictly controlled to avoid leaf burns.

- Climate conditions: Climate conditions such as temperature, humidity, light, etc. will also affect the fertilizer efficiency of BB fertilizer. Too high or too low temperature will affect the growth of crops and the absorption of nutrients. Within the appropriate temperature range, crops have vigorous metabolism, strong root vitality, and strong ability to absorb nutrients, which is conducive to improving the fertilizer efficiency of BB fertilizer. Humidity has an important influence on the dissolution of fertilizers and the conversion of nutrients. When the soil is too dry, fertilizers are difficult to dissolve and be absorbed by crops. At this time, water should be applied before fertilization; when the soil humidity is too high, fertilizers are easily lost with water, and the fertilization time should be appropriately postponed. Adequate light is conducive to photosynthesis of crops, producing more organic matter, thereby promoting the absorption and utilization of nutrients by crops. If there is insufficient light, crops grow slowly and the demand for nutrients will be reduced accordingly. At this time, excessive fertilization may cause fertilizer waste.

Market Trends and Future Prospects of BB Fertilizer

Current Global Market Trends

According to the research and statistics of the QYResearch research team, the global blended fertilizer (BB fertilizer) market sales reached 45.867 billion yuan in 2023, and is expected to grow to 69.534 billion yuan in 2030, with a compound annual growth rate (CAGR) of about 6.34% during 2024-2030.

International market world-wide:

- In many agricultural countries such as the United States and Brazil, BB fertilizers are favored because they can flexibly match nutrients and meet the soil conditions and crop needs of different regions. The market size of BB fertilizers in the United States in 2023 reached about 12 billion yuan. It is widely used in the planting of crops such as corn and soybeans, and the area of use accounts for more than 40%. The market size of BB fertilizers in Brazil is about 8 billion yuan. In the planting areas of specialty crops such as sugarcane and coffee, the application of BB fertilizers is also expanding.

- In some developed countries, the development of precision agriculture has increased farmers' demand for BB fertilizers. They customize formulas based on soil test results to improve fertilizer utilization and reduce waste and environmental pollution. For example, some European countries, due to strict environmental protection policies, have strict restrictions on indicators such as the content of heavy metals in BB fertilizers, pushing products to develop in a green and environmentally friendly direction.

- For example, Germany limits the content of heavy metals such as cadmium and lead in BB fertilizers to extremely low levels, which makes companies pay more attention to raw material screening and production process optimization in production.

Domestic Market:

- The Chinese market has changed rapidly in the past few years. The market size in 2023 is about 13 billion yuan, accounting for about 28.34% of the world. It is expected to reach 23 billion yuan in 2030, and the global share will also increase to 33.08% by then.

- In major grain producing areas such as the Northeast, BB fertilizer sales are extremely hot. In Heilongjiang and other places, its usage accounts for a high proportion, and in some areas it exceeds compound fertilizer. Taking corn and wheat planting areas as an example, the market share of BB fertilizer has increased year by year, and the sales volume of BB fertilizer in Heilongjiang Province exceeded 1.5 million tons in 2023. This is mainly due to its ability to mix fertilizers according to crop fertilizer requirements, improve yield and quality, and its raw materials are intuitive, low-cost, and easy to apply, which is in line with farmers' fertilizer habits.

- With the country's rectification of the fertilizer market and strengthening of supervision, the market order has been standardized, promoting the healthy development of the BB fertilizer industry. Overall, the global BB fertilizer market is growing, both domestically and internationally, and is moving towards a more precise, green, and efficient direction to meet the needs of sustainable agricultural development.

Innovations and Future Developments in BB Fertilizer

1. Innovations in BB Fertilizer Technology

- Precision Blending TechnologyModern BB fertilizer production lines integrate automated blending systems that ensure uniform nutrient distribution. Advanced weighing and mixing technology minimize segregation and nutrient imbalances, enhancing product consistency.

- Coating and Granulation ImprovementsRecent developments include anti-caking agents and specialized coatings to improve nutrient release efficiency and storage stability. Polymer and sulfur coatings help control the release of nutrients, reducing leaching and improving absorption by crops.

- Smart Fertilizers and AdditivesThe integration of microbial inoculants, biostimulants, and controlled-release elements enhances nutrient uptake and soil health. Smart BB fertilizers with slow-release properties improve efficiency and minimize environmental impact.

2. Future Trends in BB Fertilizer Development

- Digitalization and AI in Fertilizer FormulationAI-driven analytics and digital platforms enable precision agriculture by formulating BB fertilizers tailored to specific soil conditions and crop needs. Sensors and remote monitoring systems enhance on-site nutrient management.

- Sustainable and Eco-friendly ProductionFuture BB fertilizer production will emphasize sustainability by incorporating organic and bio-based nutrients. Reducing chemical dependency through circular economy principles, such as recycling agricultural waste, will gain prominence.

- Customization and On-Demand BlendingThe demand for highly customized fertilizers is driving the development of on-demand blending systems. Mobile blending units and localized production hubs will offer farmers greater flexibility in nutrient management.

What are the main factors affecting the growth of BB fertilizer market size in the future 2025?

1. Demand for precise Fertilization:

With the continuous expansion of the area of moderately scaled land management, the concept of precision fertilization has been deeply rooted in people's hearts. BB fertilizer is easy to produce, highly targeted, and has flexible formulas. It can customize formulas according to different soil fertility conditions and crop growth needs, meeting the requirements of precision fertilization and being favored by various large-scale new agricultural operators, thus promoting the growth of the market scale.

2. Technological progress:

The iterative upgrade and process popularization of urea coating technology have solved the problems of traditional BB fertilizers, such as short fertilizer effect, low utilization rate, and late fertilizer loss due to the rapid water solubility, easy loss, and volatilization of nitrogen, as well as fertilizer segregation and stratification caused by uneven particle size of large urea particles, which has improved the product performance of BB fertilizers, making them more competitive in the market and helping to expand the market scale.

3. Cost and cost-effectiveness advantages:

When food prices are low, farmers prefer products with high cost-effectiveness when purchasing fertilizers. The cost of BB fertilizer is transparent and controllable. BB fertilizer with slow-release effect and various nutrient enhancement additives meets the needs of farmers in terms of ensuring long-lasting and stable fertilizer effect, saving labor and energy, and high cost performance. This will increase its market demand and promote the growth of market scale.

4. Environmental protection advantages: